Electrical

requirements

Electrical Shock Hazard

Electrically ground microwave oven hood.

Do not use an extension cord.

Failure to follow these instructions could

result in death, fire, or electrical shock.

If codes permit and a separate ground wire is

used, it is recommended that a qualified

electrician determine that the ground path is

adequate.

Do not ground to a gas pipe.

Check with a qualified electrician if you are

not sure microwave oven hood is properly

grounded.

Do not have a fuse in the neutral or ground

circuit.

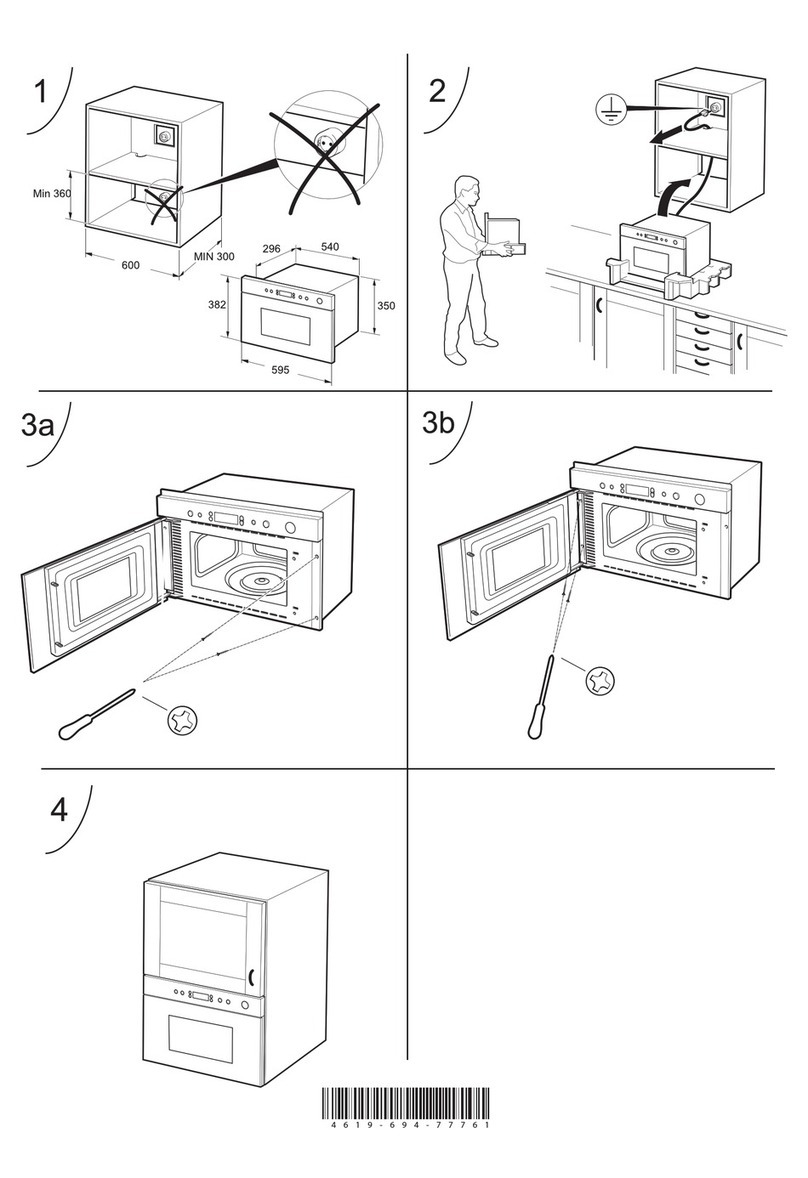

A 12Ovolt, 6OHz AC-only, 15 or 20-ampere,

fused electrical supply (located in the upper

cabinet as close as possible to the microwave

oven hood) is required. A time-delay fuse or

circuit breaker is recommended. It is

recommended that a separate circuit

serving only this appliance be provided.

Recommended ground method

For your personal safety, this microwave

oven hood must be grounded. This microwave

oven hood is equipped with a power supply

cord having a 3-prong ground plug. To minimize

possible shock hazard, the cord must be

plugged into a mating 3-prong ground-type

wall receptacle, grounded in accordance with

the National Electrical Code, ANSVNFPA

70 - latest edition (*, see Panel A), and all local

codes and ordinances. (See Figure 1.)

If a mating wall receptacle is not available,

it is the personal responsibility and obligation of

the customer to have a properly grounded,

3-prong wall receptacle installed by a qualified

electrician.

power

J-prong ground-type

wall receptacle

Figure 1

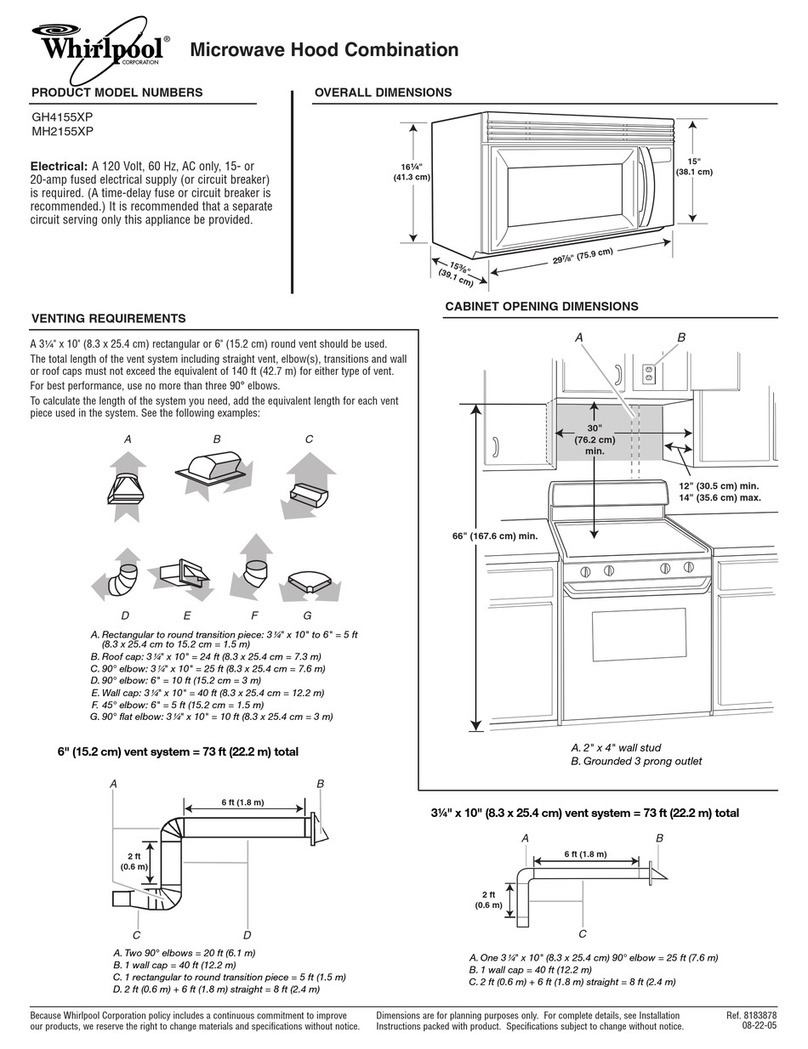

Venting requirements

Fire Hazard

Venting system must terminate to the

outside.

Do Not terminate the duct in an attic or other

enclosed space.

Do Not use four-inch laundry-type wall caps.

Do Not use plastic duct.

Failure to follow recommended venting

procedures may result in a fire.

CAUTION: To reduce risk of fire and to

properly exhaust air, be sure to duct

air outside. Do Not vent exhaust air

into spaces within walls or ceilings or

into attics, crawl spaces or garages.

Duct needed for Installation is not included.

Wall and roof caps used must have back-draft

damper.

Use metal duct only. Rigid metal duct is

recommended.

Flexible metal duct is Not recommended. If

flexible metal duct is used, calculate each foot

of flexible metal duct as two feet of straight

metal duct. Flexible metal elbows count twice

as much as standard elbows.

Determine which venting method (roof-venting

or wall-venting) you need to use.

This microwave oven hood is equipped for

ventless (recirculating) installation.

The length of the duct and number

of elbows should be kept to a minimum to

provide efficient performance. The size of duct

should be uniform. Do Not install two elbows

together. Use duct tape to seal all joints in the

duct system. Use caulking to seal exterior wall

or roof opening around cap. Figures 2-5 show

common venting methods and types of

materials needed.

Note: If the rear exhaust method is chosen, be

sure that there is proper clearance within the

wall for the exhaust duct.

Roof venting Wall venting

Figure 2

roof cap

3-1/&x lo”

duct .

through-the-roof

Figure 3

ewa~~‘-

round duct

3-l/4” x lo” to

round duct transition

transition

Figure 5

Recommended duct length

Use 3-l/4” x lo” or 6” duct. The total length of

the duct system including straight duct,

elbow, transitions, wall or roof caps must not

exceed the equivalent of 140 feet of 3-l /4” x

10” rectangular or 6” diameter round duct. For

best performance, use no more than three 90”

elbows. To calculate the length of system you

need, add the equivalent feet for each duct

piece used in the system. See the following

examples:

3- l/4” x lo” duct system

u

1 - 3-l/4” x 10”

90” elbow = 25 r-t.

1 - wall cap = 40 ft.

8 feet straight = 8ft.

Length of

3-l /4” x lo” system = 73 ft.

6” duct system

tronbtion

1 - transition = 5ft.

2 - 90” elbows = 20 f?.

1 -wall cap = 40 ft.

8 feet straight = 8ft.

Length of 6” system = 73 ft.

Recommended standard fittings

3-l/4” x lo” roof 3-1/4”x 10”

cap= 24ft. 90” elbow= 25ft.

f

If the existing duct is round, a rectangular-to-

round adapter must be used and a

rectangular 3” extension duct between the

damper assembly and the adapter must be

installed to prevent sticking of the exhaust

damper.

3-l/4” x 10” through-the-wall

Figure 4

Panel B