Before you start...

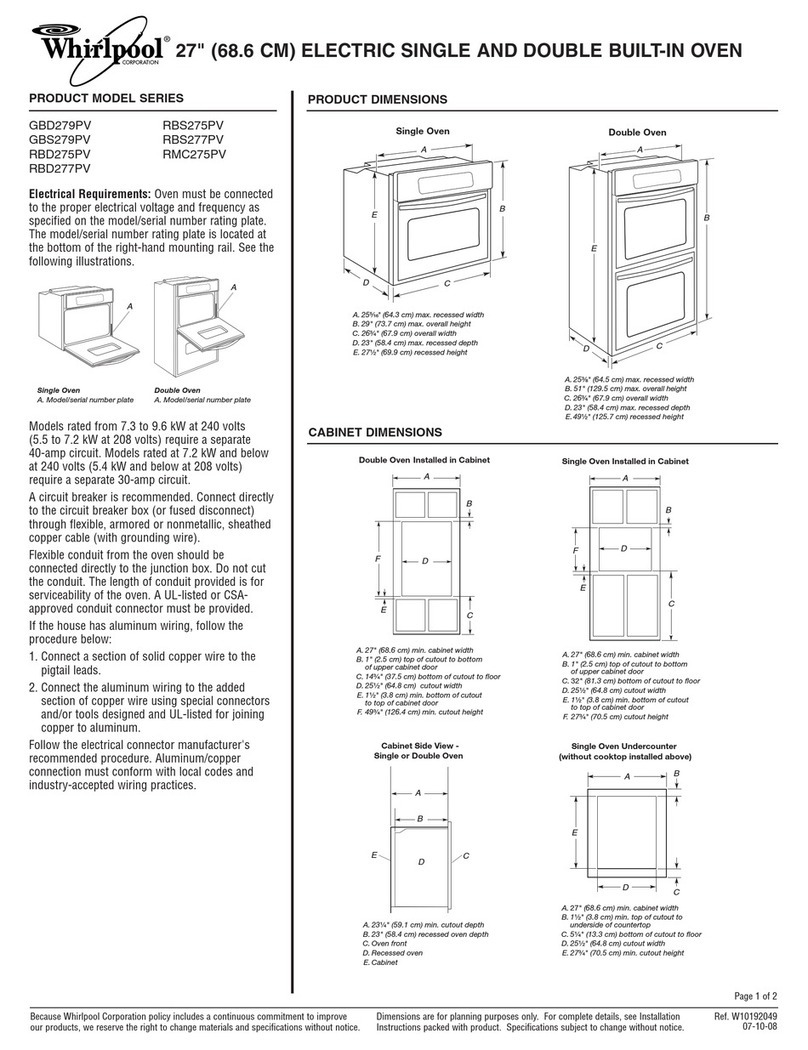

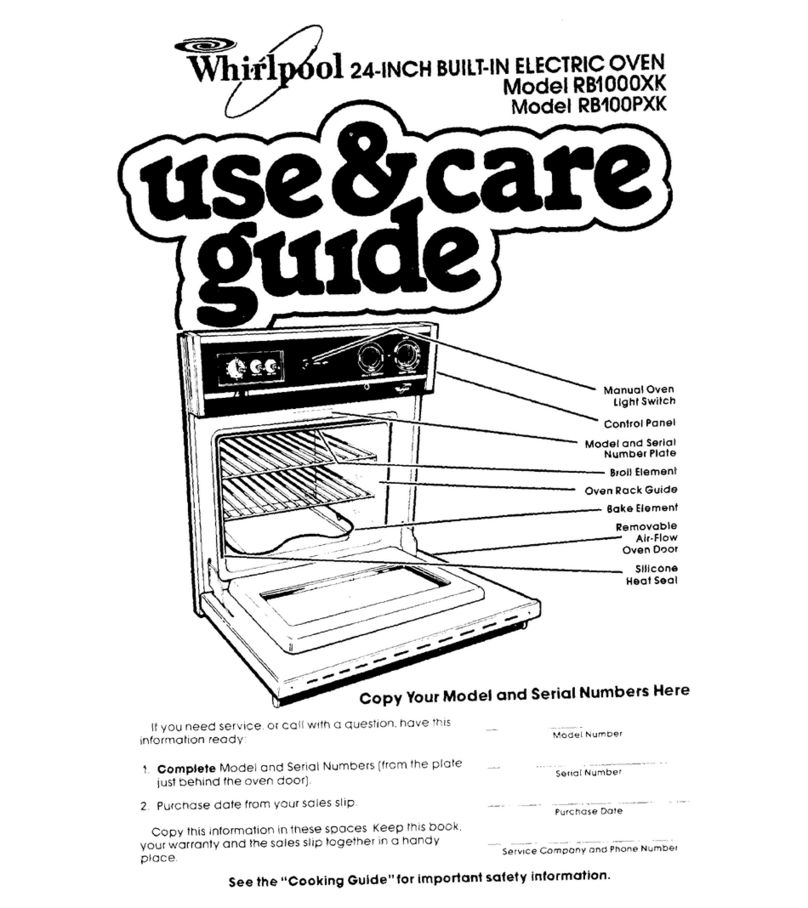

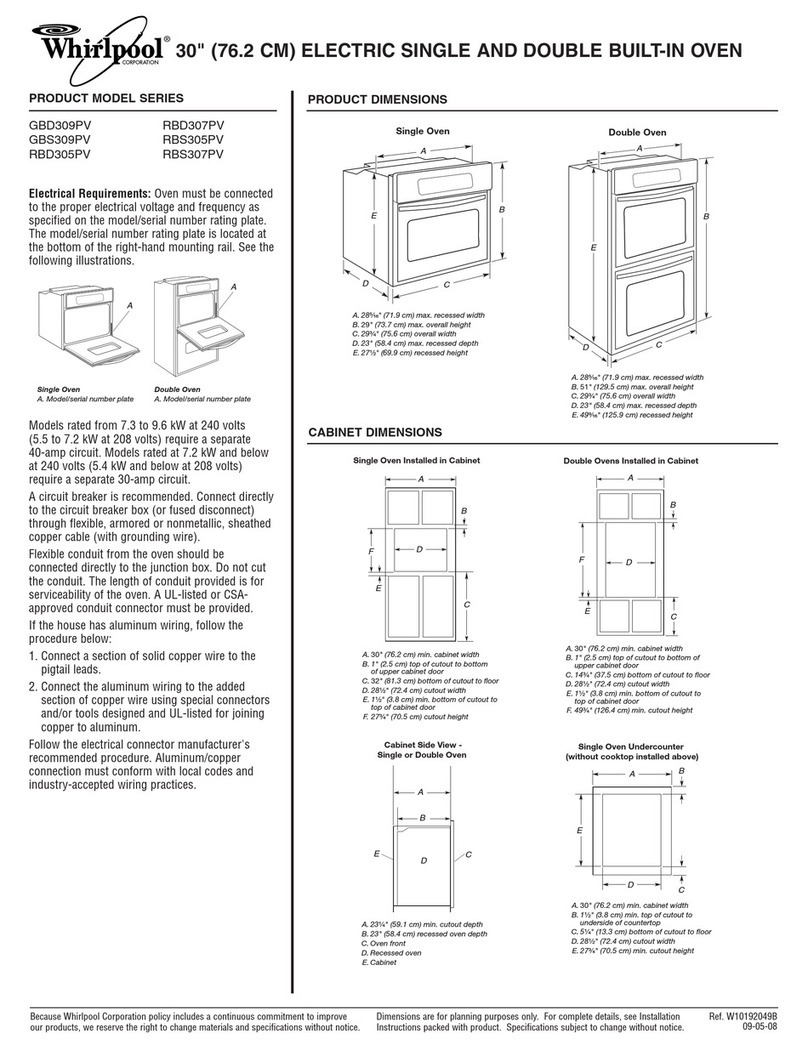

Check locahon where wall oven ALL OPENINGS IN THEWALL

will be installed The location OR FLOOR WHERETHE

Proper Installation isyour responsibility should be away from strong draft WALL OVEN ISTO BEINSTALLED

Make sure YOUhave evervihlna necessarY areas, such as windows. doors. MUST BESEALED.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches

3. Extinguish any open flame.

4. Immediately call your gas

supplier.

for correct /nstallation It ii the &sponsibili$ and strong heating vents of fans.

of the installer to comply with the installation The wall oven should be

clearance specified on the serial/rating located for convenient use Note: Clearances specified

plate. The serial/rating plate can be in the kitchen. are for combustible walls and

?oven frame behind the materlals that have a density Of

found on tht

lower oven ( ( Given dimensions provide 0”

clearance Dlmenslons aiven clearances has been

made for installations

are for wall oven sitting On adjacent to materials that

cabinet floor. Cabinet floor must are lessthan 20 pounds

be solid and level. per cu. ft. or to plastic tiles

and sheeting.

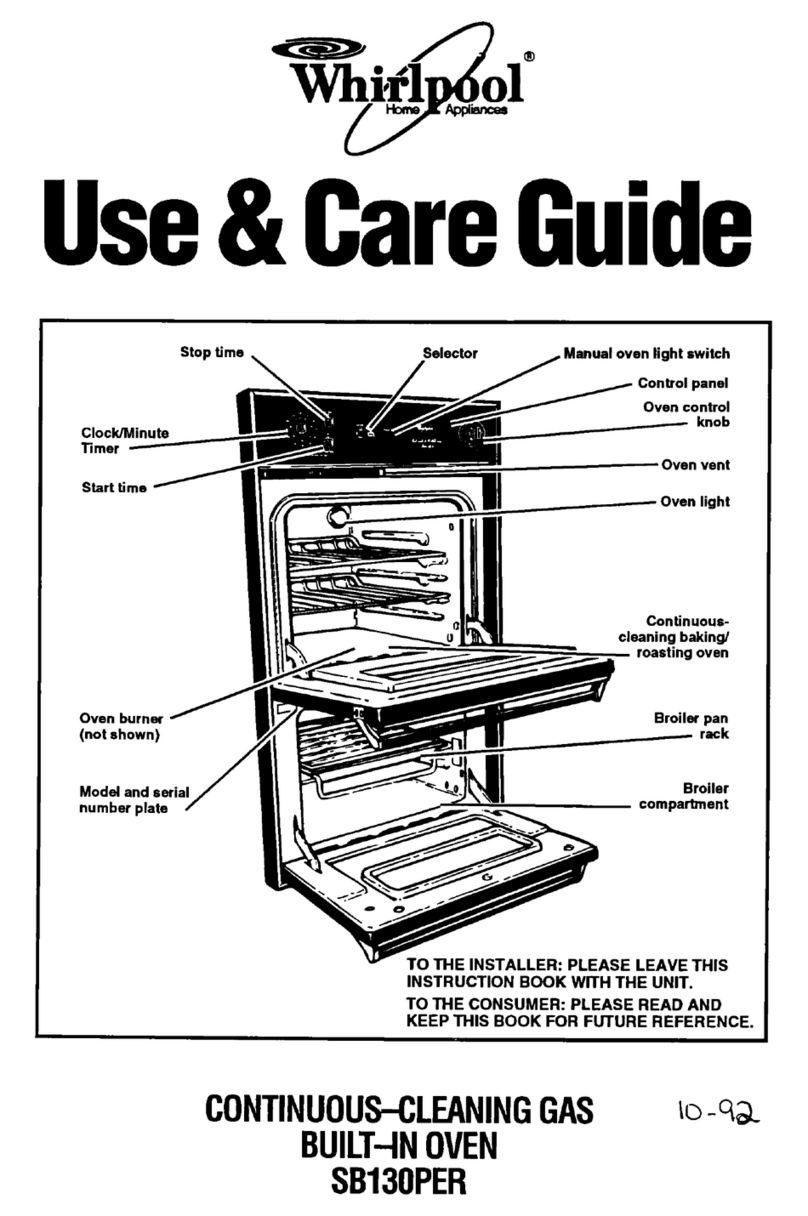

FOR YOUR SAFETY 1

z;EzFd (

liquids in the vlcmlty of this

Depthlo control

1FOR YOUR SAFETY 1

Do not obstruct the flow of

combustion and ventilation air.

IFOR YOUR SAFETY I

The maximum gas suppl

pressure for this

must not exceed

Important: Observe all govemlng

coder and ordlnancesfollure t6 meet

codes and ordinances could lead to

tire or electrical shock hazard.

Moblle Home lnstallatlon

The installation of this wall oven must

conform to the Manufactured Home

Construction and Safely Standards. Title

24 CFR. Part 32-80 (formerly the Federal

Standard foeMobile Home Construction

and Safety, ntle 24, HUD (pail 280)).

Copies of the standard listed above

may be obtained from:

-American

Gas Asoclatlon

1515Wilson Boulewrd

Mlngton.Vlrglnla 22209

l

*Natlonal Fire ProtectIon Awclatlon

Botierymarch Park

Qulncy,

Massachuseftr 02269

Grounded electrical outlet: isrequired

See Electrical Requirements.

Proper gas supply connection must be

me

recessed lnstallatlon area must

available. See Gas Supply provide complete enclosure around the

Requirements. recessed portion of the oven.

Tools needed for installation.

C

Thiswall oven Isequipped faf

n use with NATURAL gas. It is

certified bv A.G.A. for NATURAL and L.l?

gases with appmpriate conversion. The

serial/rating plate located on the oven

frame behind the broiler door has

information on the type of gas that can

be used Ifthis informatlon daes not

agree with the type of gas avallable.

check with the local gas suppller. See

Backcover for L.F!gas conversion

instructions. -

D

n Provide a gas supply line of

%” rigid pipe to the wall oven

location either thrwah the wall or

cabinet floor. Keep &e near the wall.

The wall oven gas fittIne is Itied al

uaaer left side of aooliance. Pipe lolnt

compounds resistait’to the acti& bf LJ?

gas must be used. with L.F!gas, plplng 0T

tubing size can be Yz”minimum. L.F!gas

supplIers usually determine the size and

materlals used on their system.

Gas Supply

Requirements

Obsek all govemlng codes

and ordinances.

G

If rtgl

n supply line, a combination of

pipe fittings must be used to obtain an

in-line connection to the wall oven. All

strains must be removed ham the suwlv

E

If local codes permlt, A.G.A.

n certified flexible metal tubing

(new) ISrecommended far connecting

this wall oven to the gas supply line. Do

Not kink or damage the flexible tubing

when moving the wall oven. A Y2Nmale

pipe thread isneeded for ccnnectian to

pressure regulator female pipe threads.

A

n This installation must conform

with local cc&s and and fuel lines so wall oven will be leb&l

and in line

H

The inlet pressure to the

n regulator should be as follows

for both operation and checking

regulator setting:

NATURAL GAS:

Mlnlmum pressure5 Inches

Maxlmum pressure 14 Inches

L.F!GAS:

Mlnlmum pressure 11Inches

Maxlmum pressure 14 Inches

ordinances. In the absence of local

codes. installation must conform with

American National Standard, NatIonal

Fuel Gas Code ANSI 2223.14984:

-I

The wall oven and ik Individual

n shut-d valve must be

dIsconnected from the gas supply

piplng system during any pressure

testing of that system at test pressures

in excess of YZpsig (3.5 kPa].

The wall oven must be lkolated from the

gas supply piplng System by closing its

individual manual shutoff valve duting

any pressure testing of the gas supply

piping system at test pressures equal to

or lessthan Yzpsig (3.5 kPa].

The supply line should be

equipped with a shut-off valve.

Thisvalve should be located in the same

rmrn as the wall oven and should be in

a location that allows ease of apenlng

and closing. Do Not block access to

shukff valve.

Thiswall oven isequipped with an oven

burner shut-off valve located on the wall

oven manifold.

the serial/rating

plate ore

for elevations up to 2,aw) feet. For

elevations above 2.ooO feet, ratings

should be reduced al a rate of 4%

for each 1,ooOfeet above sea level.

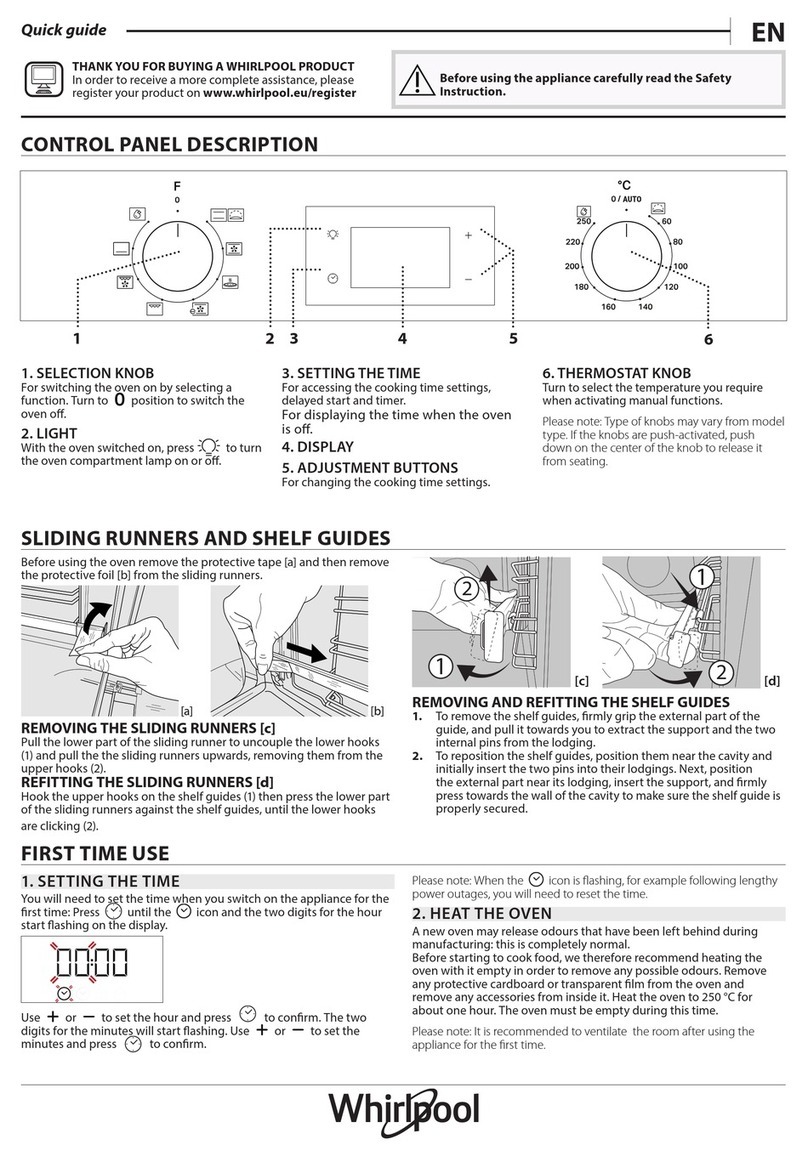

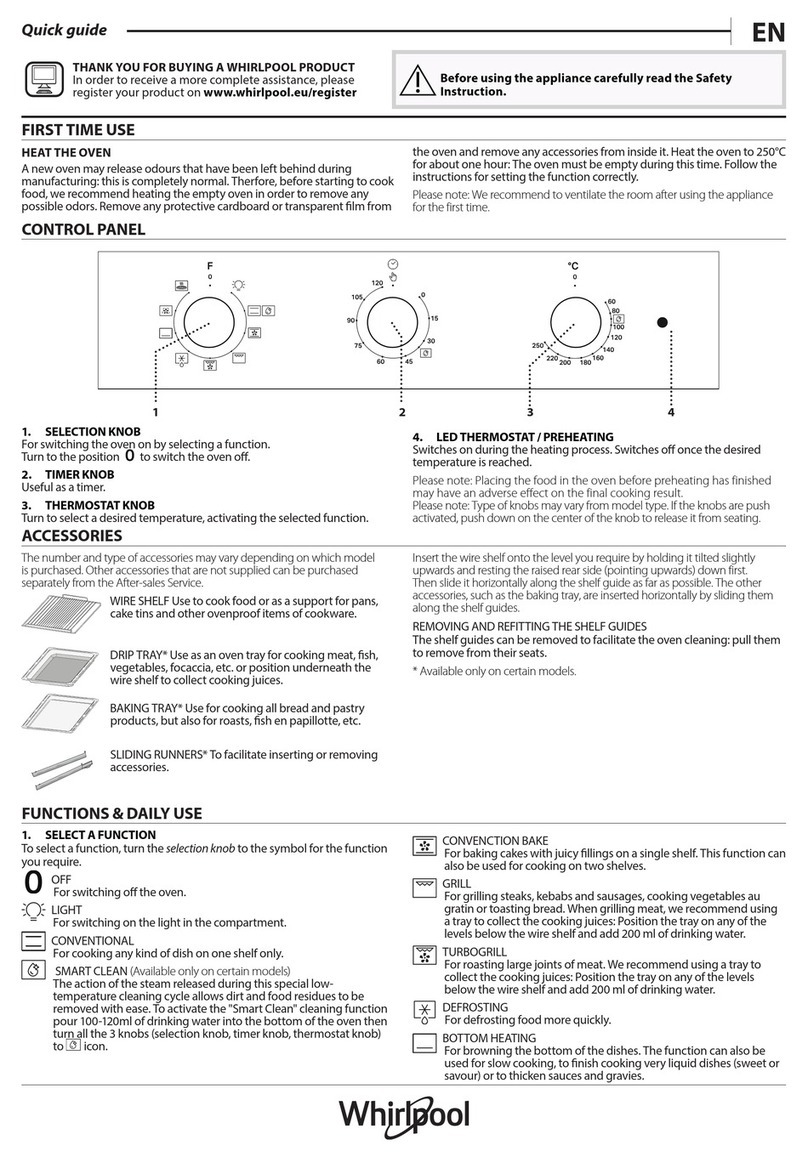

PANELA