7

Make Electrical Connection

GROUNDED UNGROUNDED

NEUTRAL NEUTRAL

JUNCTION

BOX \

FROM POWER

S”Y”“’

(p

3r-

GREEN OR

BARE WIRE

APPLIANCE

COPPER GROUNDED COLD

GROUND WIRE WATER PIPE

\ (REMOVE PAINT, ETC.)

JUNCTION FROM POWER

BOX \ FOURCE

EN

FIRMLY ACK

GROUND CLAMP

(MUST BE TIGHT

ON PIPE)

Connect the flexible armored cable that extends from the

surface unit to the junction box using a suitable strain

relief at the point the armored cable enters the junction

box. Then make the electrical connection as follows:

It is the personal responsibility and obligation of the cus-

tomer to contact a qulaified installer to assure that the

electrical installation is adequate and is in conformance

with the National Electrical Code and local code ordi-

nances.

Electrical ground is required on this appliance.

This appliance is equipped with copper lead wires. If con-

nection is made to aluminum house wiring, use only special

connectors which are approved for joining copper and alu-

minum wires in accordance with the National Electrical

Code and local codes and ordinances. This appliance is

manufactured with a white neutral power supply wire and a

frame connected green (or bare) ground wire twisted together.

If local codes permit connection of the frame grounding

conductor to the neutral (white) wire, connect the green

(or bare wire) and white wire from the supply cable of the

appliance together and the neutral (white) wire in the junc-

tion box. Connect the remaining wires from the supply

cable to the wires in the junction box. See Figure 10.

If local codes DO NOT permit frame grounding to the neu-

tral, separate the white (and green or bare wires) that extend

GREEN OR

BARE WIRE

out of the end of the supply cable of the appliance. See

Figure 12. Connect the white wire from the supply cable to

the neutral wire in the junction box. Connect the black (or

brown) and red wire from the supply cable, to the corre-

sponding wires in the junction box. The green (or bare)

wire must now be used to ground the appliance in accord-

ance with local electrical codes. Connect the green colored

copper (or bare) ground wire to a grounded cold water pipe*

(see Figure 11) or to the grounded lead in the service panel.

Do not ground to a gas supply pipe. Do not connect to

electric power supply until appliance is permanently ground-

ed. Connect the ground wire before turning on the power.

(See Figure 11.)

CAUTION - If connecting to a four-wire electrical sys-

tem (MOBILE HOME) the appliance frame MUST NOT

be connected to the neutral wire of the four-wire electri-

cal system. Separate the white (and green or bare wires)

that extend out of the end of the supply cable of the ap-

pliance. Connect the white, red and black (or brown)

wires from the supply cable, to the corresponding wires

in the junction box. Connect the green(or bare) wire from

the supply cable to the ground wire in the junction box.

(See Figure 12)

*Cold water pipe must have metal continuity to electrical ground

and not be interrupted by plastic, rubber or other electrically in-

sulating connectors (including water meter or pump) without

adding a Jumper wire at those connections.

Connectingthe

Vent System

Connect Venting Adapter on bottom of ap-

pliance to installed venting system (refer to

pages 4 and 5 for venting instructions).

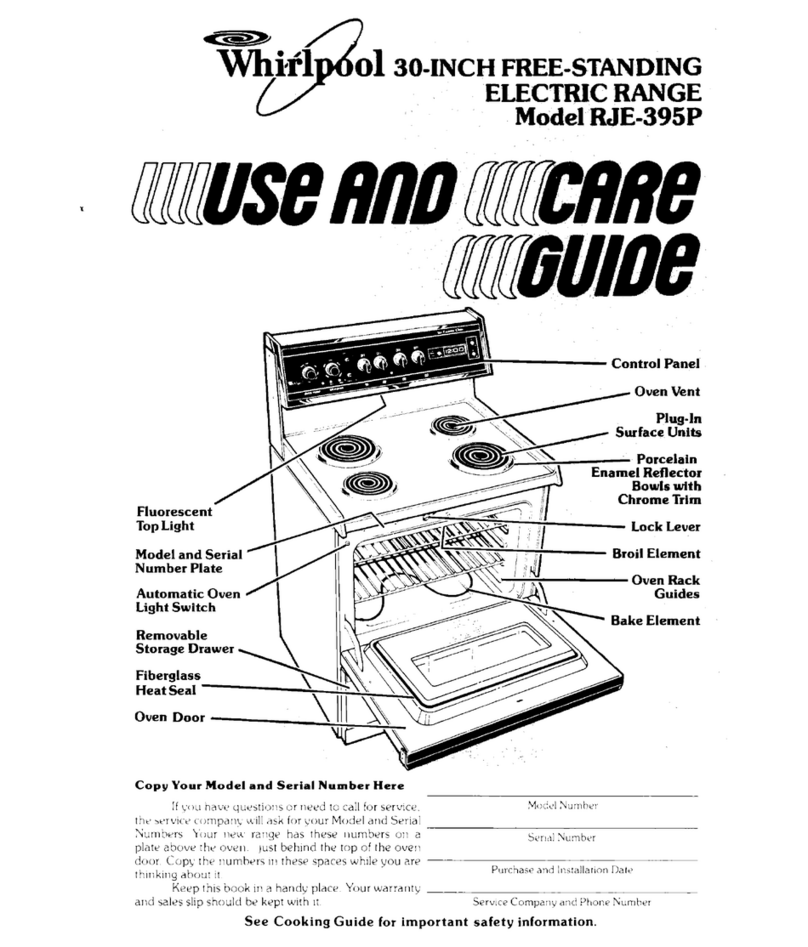

CheckOperation

When all connections for the appliance have

been made, turn each control on to make

sure the components are operating correctly.

For instructions on operating, cleaning and

maintaining this appliance, refer to Use and

Care Guide in the Literature Package.