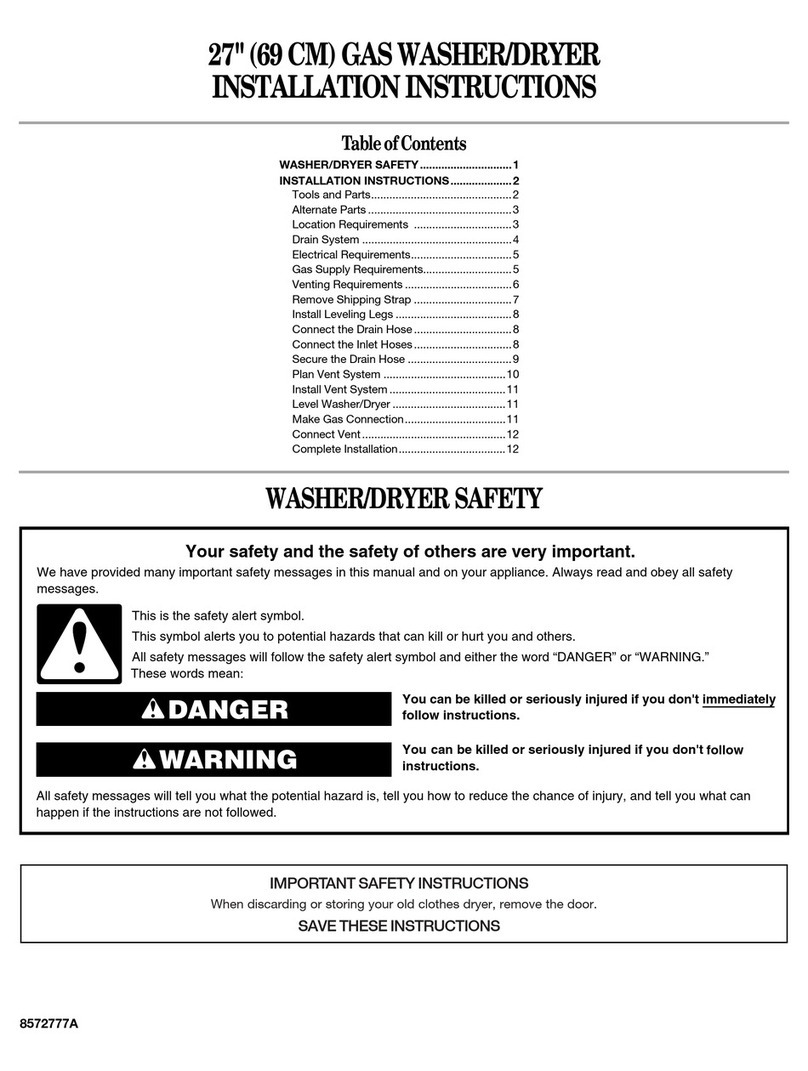

I

Befom you start...

Mark an X across the letter or

number as You complete each step.

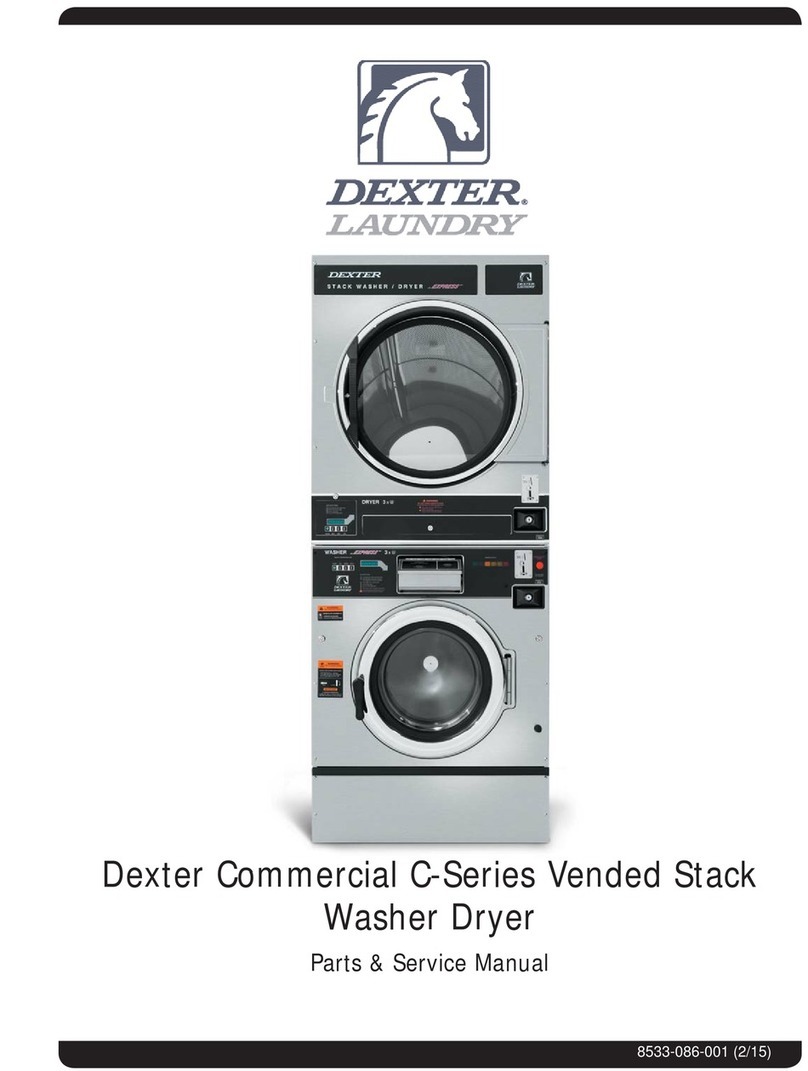

phllllps screwdriver

RECOMMENDED GROUNDING

MErHoD

Electrical ground Isrequired on

lhls appliance.

DO NOT. UNDER ANY

CIRCUMSTANCES, REMOVE THE

POWER SUPPLYCORD GROUND

PRONG

Foryour personal safety. this

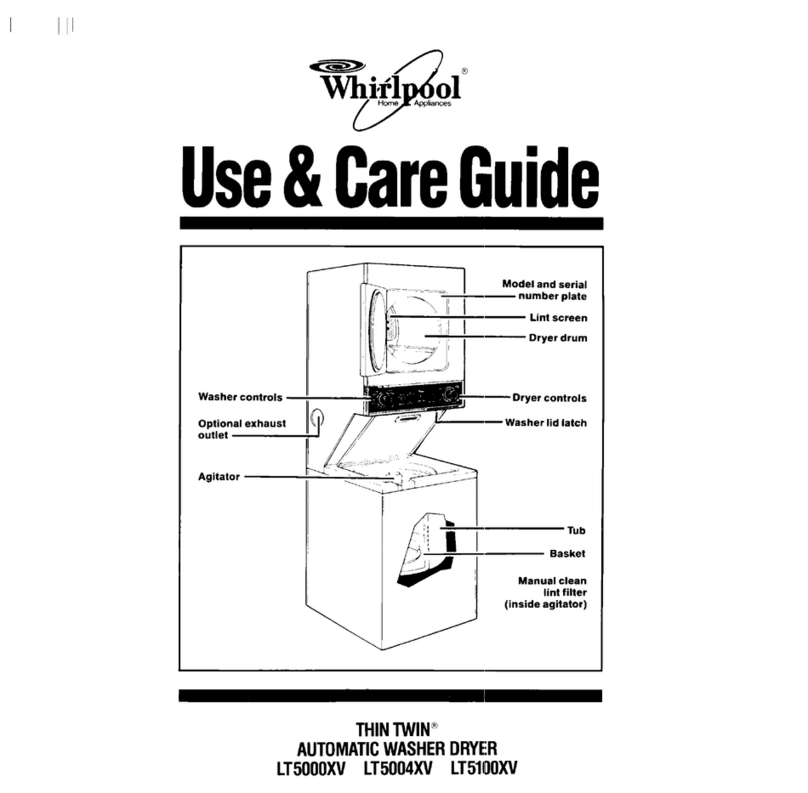

You need these tools to install your

Whirlpool washer/dryer. Get fhem

together in one place to keep

hack of them.

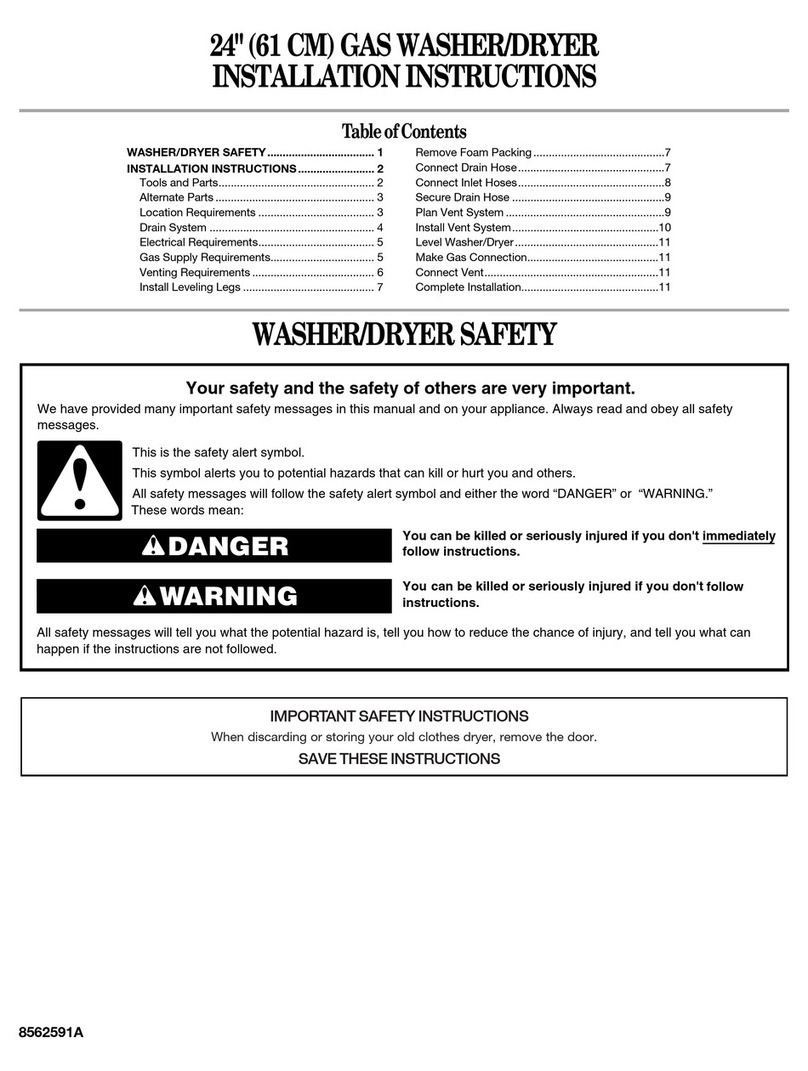

B.

Check

the spot where

you’re going

to install the

wosher/dryer...proper

installation isYour responsibility

Make sure you have everyihing

necessary for proper installation.

You’ll need:

To meet code reaultemenh:

some codes keep from or limit

installation of clothes drvers in

garages, closets. mobile homes

and sleeping quarters. (Check

with your local building inspector.)

Important: observe all

gavemlng codes and

ofdlnances.

LOCAOII

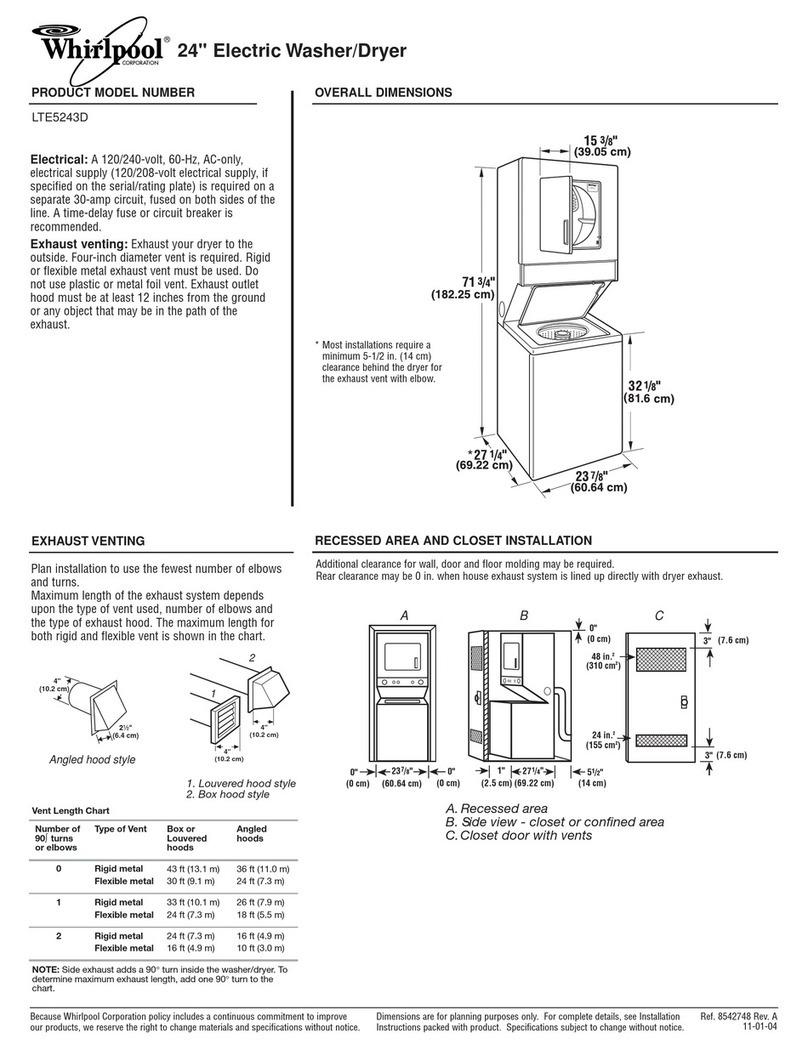

Size: Must be large enough to fully

open dryer door. Fof recessed of

closet installations see Panel Efor

spacing. for product dimensions

see buck page of these

instructions.

Support: The floor must be able

to support the appliance weight

of 375 pounds.

Level Floor: Maximum floor slope

under washer/dryer 1inch

ProteCtIon from the weather:

Proper operation of dryer cycles

requires temperatures above 45°F

As some water remains in the

washer do not store or operate the

washer below 32°F For storaae

below 32°F see Laundry Guize for

“Winterizing:’

CWTION:

l

It isthe person01 responsibility of

the customer to ensure that

gasoline. paint, thinners and

other flammable moteriols are

not used or stored near the

washer/dr/er. Fumes from these

materials could result in fire or

explosion.

l

Never install the washerldryer

up against droperies or curiains

and be sure to keep ony and all

items from falling or collecting

behind the washer/dwer

l

Replace oil access or service

panels before operating

wosher/drYer

Elect&al Requirements

WARNING: Imptaper connection

of the equipment grounding

conductor can result In a risk ot

electdcal shock.

A 120volt. 60 Hz.AC only 15

ampere fused electrical supply

isrequired [time-delay fuse or

circuit breaker isrecommended],

If Your home has a circuit wired

and fused for 20 amperes, this is

preferred. If yourare installing a

new circuit, one wired and fused

for 20 amperes is recommended

It isalso recommended that a

separate circuit serving only this

appliance be provided. DO NOT

use on edension cord.

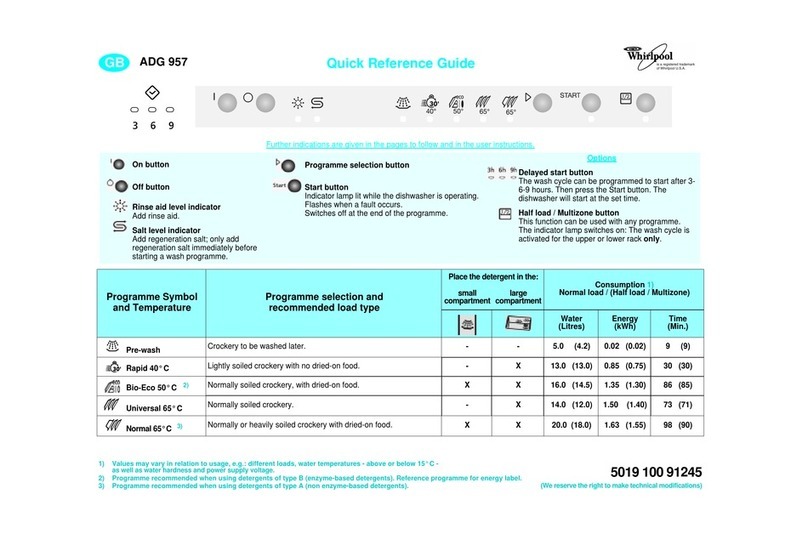

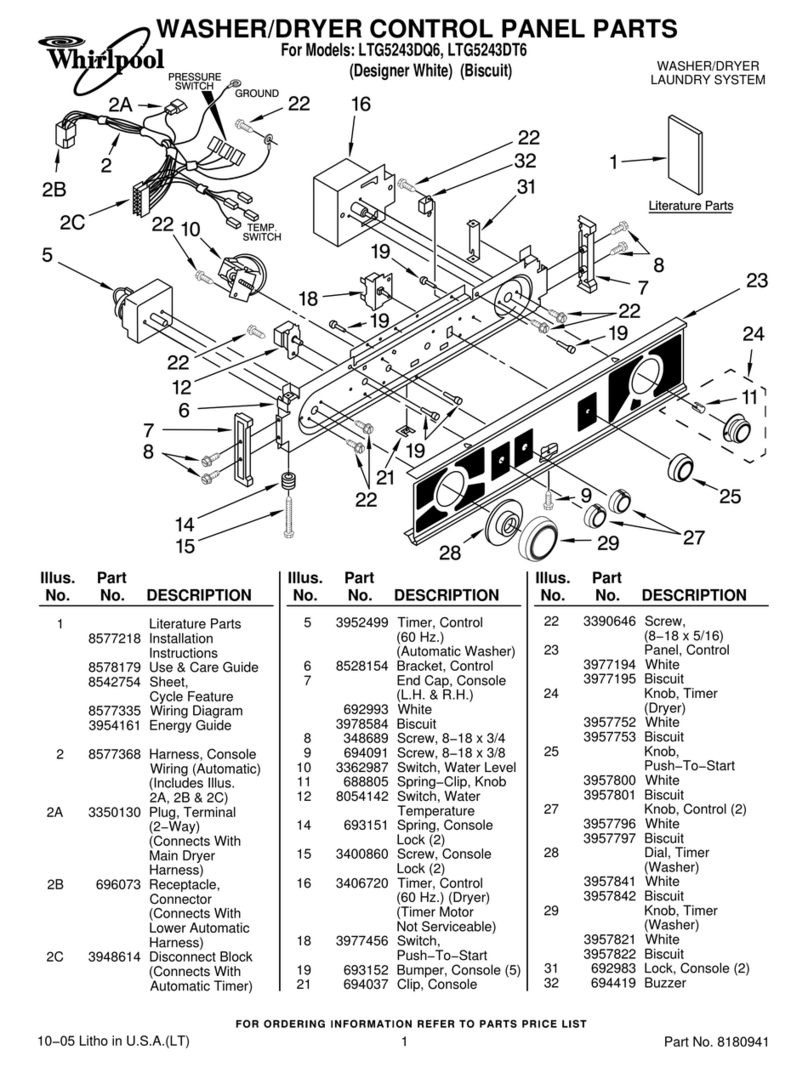

PANEL A

appliance musi be grounded

Thisawliance iseauioaed with

a power supply cord Ii&g a

J-prong grounding plug. To

minimize possible shock hazard.

the cord must be plugged into a

mating 3-prong QrcundinQ tvpe

wall r&eptacle. grounded in

accordance with the National

Electrical Code. ANSI Cl-1984 and

local codes and ordinances.

See Figure 1.If a mating Wall

receptacle isnot available. it is

the penonal responsibility and

obligation of the customer to have

o properly grounded J-prong wall

receptacle installed by a

qualified electrician.

For added personal safety. use

clomp and areen colored

cop&r QrOUndinQ wire. Connect the

Qroundlng Wire (#14 minimum] from

the exlernol grounding connector on

the bock of the appliance to 0

Supply Card

ALTERNAlE GROUNDING METHOD

DO NOT, UNDER ANY CIRCUM-

STANCES, REMOVE THEPOWER

SUPPLYCORD GROUNDING PRONG.

If changing and properly

Qroundina the wall receptacle IS

Imble or-d where local codes

permit fconsult vourelectrical

&zsciorl. a ter&ororv adapter

may be plugged into the existing

2-prong wall receptacle to mate

with the 3.prong power supply cord

THIS.HOWEVER. ISNOT

RECOMMENDED.

If this isdone. vou must connect o

separate copper grounding wire

(#I4 minimum] to 0 grounded

cold water pipe’ by means of a

clamp and then lo the external

grounding connector screw. Da

nol ground lo a gas supply pipe.

Do not connect to electrical

supply until appliance is

Exhaust requirements

Pour Inch Metal Exhaust Duel is

required [Do not use 3 inch

exhaust duct.) Melal flexible duct

may be used. Non-metallic

flexible duct isnot recommended

For Safely:

l

Do not exhaust dryer into a

chimney. furnace cold air duct.

attic or crawl space. or any

other duct used for venting.

Accumulated lint could

become a fire hazard or

moisture could cause damage.

. The exhaust system should be

cleaned periodically. ot least

every 2 Years.

. Flexible duct should never be

installed concealed in walls.

ceiling 0Tfloor

use Duct Tape

to seal all joints.

Bhausllng lhe

dryer oulslde is

recommended. If

You cannot exhaust the

V

dryer to the outside. use Exhaust

Deflector Kit LCK4500 available

from Your Whirlpool dealer.

Exhausting Me dryer thrcugh

the side isavailable wlth use

of Side Exhaust Kil LCK46M). Follow

the installation instructions with the

kit for proper exhaust instollotion.

For Moblle Home Exhaust

Requlremenis see Panel E.

Alternate Exhaust Methods. for

detailed instructions.

Metal Flexible Duct must be fully

exiended and supporled when

the dryer isin its final position. Do

NOT KINK OR CRUSHTHEDUCT.

The Exhaust Duct should end

with an exhaust hood to prevent

exhausted oir returning into dryer

The outlet of the hood must be

at least 12inches from the ground

or anYthing else that may be in

the path of the exhaust.

A 2R inch outlet Exhaust Hood

should be used with shoalsystems

only Thisoutlet creates greater

backward pressure than other

hood types.

Exhaust Hoods with magnetic

latches should not be used

The Maxlmum Length of the

exhaust system depends upon the

vpe of duct used. number of

elbows and type of exhaust hood.

The maximum length for both rigid

and flexible duct isshown in chart

Exhaust Systems longer than

specified ~111:

l

Shorten the life of the dryer.

l

Reduce the performance. such

as cause longer drying times

and increase the use of energy

. Accumulate lint.

Hot and Cold water f

within 4 feet of back of the

washer/dryer and enough

pressure (51W PSI)are required

Waler Healer should be set to

deliver 13o’F or above water to

the washer for best results.

ToDmln the Whirlpool washer.

You need either a Atk

20 gallon laundry

tub or a two inch

diameter standpipe

having a minimum

carry-away capucity of

17gallons perminute. ’

The top of the tub or the top of the

standpipe cannot be lower than

28 inches or higherthan 48 inches

from the bottom of the StandpIpe

washer. Use a floor drain

only if o siphon break

[air valve to equalize

pressure] is installed.

[A siphon break, Part No.

285320 isavailable from

Whirlpool authorized

parts distributor.]