Addition £eat res

Electrical Shock Hazard

Disconnect power before making

electrical connections,

Failure to do so can result in death

or electrical shock.

ForWARM RINSE:

o Remove screws from each end of

the console bottom,

Pull the console bottom forward;

lift and tilt back,

Connect J] to J2

ToSAVEWATER:

o Locate water level switch on

back of washer, (See Back Page,)

Turnshaft 45° counterclockwise,

Check I{st {bt washer

opeta[{on

CBeck the following if the washer is

not operating properly:

1. Power supply cord is plugged in,

2. Circuit breaker is not tripped or fuse

blown,

3. Timer has been advanced to start

of a cycle,

4. Water faucets are turned on,

5. Inlet and drain hoses are not

kinked,

5. Washer lid is closed,

7. Inlet valve isfrozen if not protected

from the weather,

8. Suds level, Excess suds will slow the

spin and cause poor rinsing,

Operate the washer through a

complete cycle with no detergent,

Use less detergent or a controlled

suds type detergent in future loads,

If need

a$$1$tance...

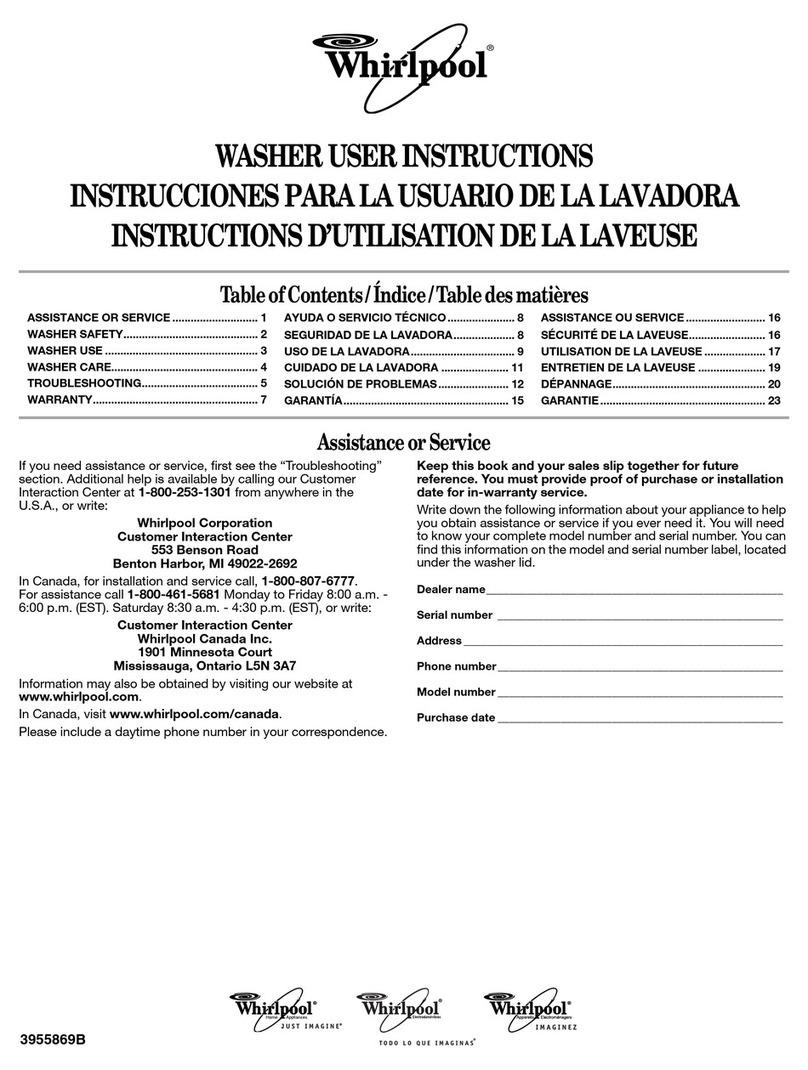

The Whirlpool Consumer Interaction

Center will answer any questions

about operating or maintaining your

washer not covered in the Installation

Instructions, The Whirlpool Consumer

Interaction Center isopen 24 hours

a day, 7 days a week, Just dial

1-800 NO BELTS(1-800-662-3587) --

the call is free,

When you call, you will need the

washer model number and serial

number, Both numbers can be found

on the serial-rating plate located on

your appliance,

PAGE 6

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the riskof fire, electric shock, or injury to persons

when using your washer, follow basic precautions, including the following:

oRead all instructions before using

the washer,

o Do not wash articles that have

been previously cleaned in,

washed in, soaked in, or spotted

with gasoline, dry-cleaning

solvents, other flammable or

explosive substances as they give

off vapors that could ignite or

explode,

• Do not add gasoline, dry-cleaning

solvents, or other flammable or

explosive substances to the wash

water, These substances give off

vapors that could ignite or

explode,

o Under certain conditions,

hydrogen gas may be produced in

ahot water system that has not

been used for 2 weeks or more,

HYDROGEN GAS ISEXPLOSIVE, If

the hot water system has not been

used for such aperiod, before

using awashing machine, turn on

all hot water faucets and let the

water flow from each for several

minutes, This will release any

accumulated hydrogen gas, As

the gas isflammable, do not

smoke or use an open flame

during this time, SAVE THESE

o Do not allow children to play on or

in the washer, Close supervision of

children is necessary when the

washer is used near children,

• Before the washer isremoved from

service or discarded, remove the

lid,

• Do not reach into the washer if the

tub or agitator is moving,

• Do not install or store this washer

where it will be exposed to the

weather,

• Do not tamper with controls,

• Do not repair or replace any part

of the washer or attempt any

servicing unless specifically

recommended in the Owner's

Manual or in published user-repair

instructions that you understand

and have the skills to carry out,

• See Page 3 of this booklet for

recommended grounding

instructions,

INSTRUCTIONS

Fora grounded, cord-connected

appliance:

GROUNDING INSTRUCTIONS

This appliance must be grounded, In

the event of malfunction or

breakdown, grounding will reduce

the riskof electric shock by providing

a path of least resistance for electric

current, This appliance isequipped

with acord having an equipment-

grounding conductor and a

grounding plug, The plug must be

plugged into an appropriate outlet

that is properly installed and

grounded in accordance with all

local codes and ordinances,

WARNING - Improper connection of

the equipment-grounding conductor

can result in arisk of electric shock,

Check with aqualified electrician or

serviceman if you are in doubt as to

whether the appliance is properly

grounded,

Do not modify the plug provided with

the appliance - if if will not fit the

outlet, have aproper outlet installed

by aqualified electrician,

For a permanently connected

appliance:

GROUNDING INSTRUCTIONS

Thisappliance must be connected

to a grounded metal, permanent

wiring system, or an

equipment-grounding conductor

must be run with the circuit

conductors and connected to the

equipment-grounding terminal or

lead on the appliance,