7

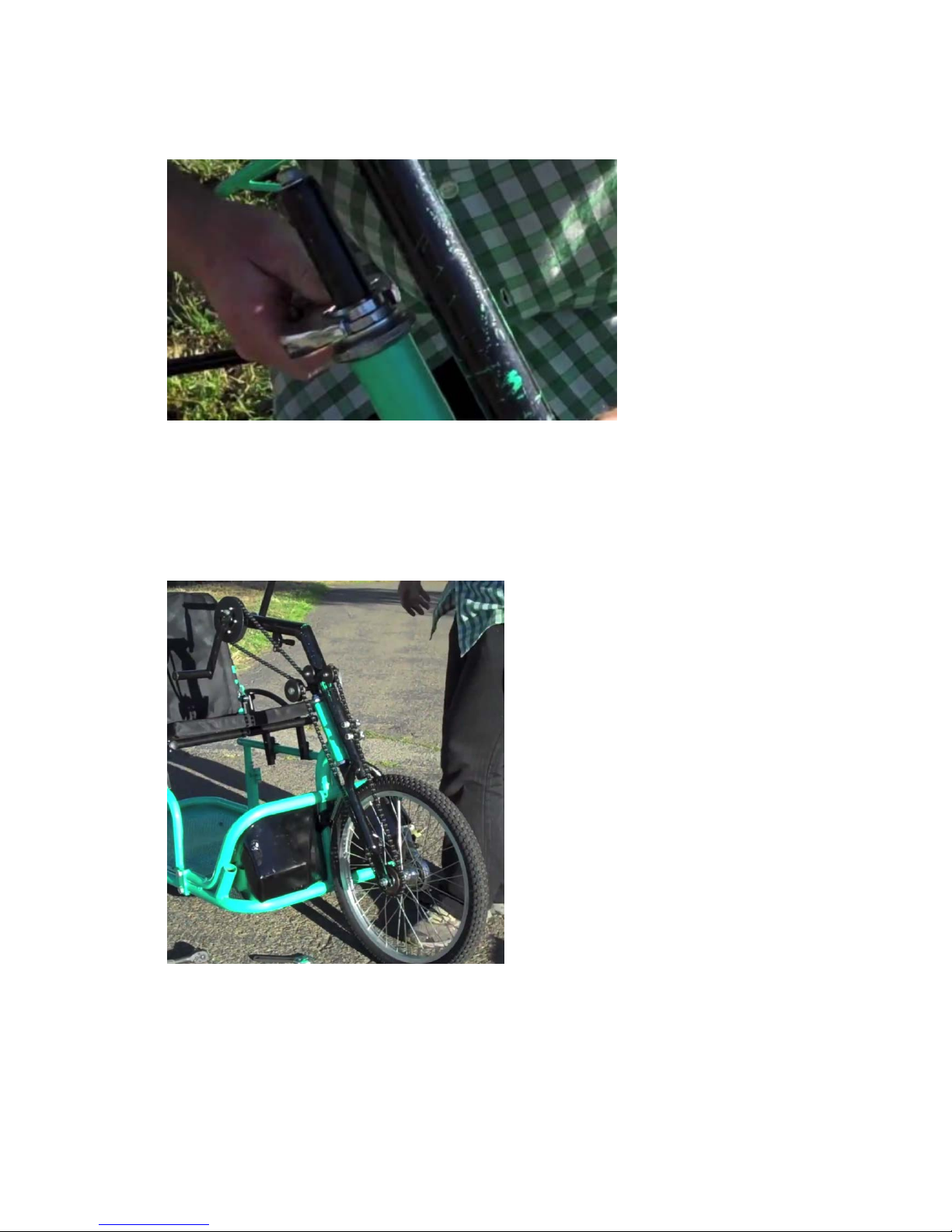

The following components are pre-assembled:

•Bottom bearing cone “crown race” installed on fork steerer tube

•Top and bottom bearing cups are installed in head tube on front of mainframe

•Chain idler wheels (2) installed on rotating bar of chain idler, with torsion spring installed.

•Tensioned chain idler pulley with bearings is installed securely.

•Rear wheel clamp bolt and lock bolt are installed on rear main frame.

•Center spring clamp is installed on front main frame

•Bolt and wedge are installed on stem quill.

•Chain Idler brace is installed on crank boom

•Bottom bracket is installed on Crank Boom, with the long side of the bottom bracket spindle on

the right side when viewed from the back of the trike.

•Handrims, rim strip, tube, and tire are installed on rear wheels. Refer to the RoughRider

wheelchair assembly materials available from Whirlwind. Note: There are different left and right

wheels. The right wheel has the adjustable cup of the hub on the same side as the handrim,

and the left wheel has the fixed cup on of the hub on the same side as the handrim.

•The crank chain ring has chain guards discs installed on both sides of the cog.

•Hand grips are installed onto “pedals”/ crank arms.

•The TAB tension adjustable backrest straps are installed on the backrest posts.

•Brake lock parts are attached to brake arm.

•Brake plastic bushings are installed on brake pivot tubes.

•Foot guards are installed.

•Centering spring clamp protector is installed.

•Fenders are installed on seat.

•Quick release bolts installed on crank boom and idler brace.