Whirlwind Inc.

4302 Shilling Way Dallas, TX USA 75237

(214) 330-9141 Fax (214) 337-9572

www.whirlwindsaws.com

Whirlwind Model 216 Cut-Off Saw Owner's Manual

Table of Contents

----------------------------------------------------------------------------

----------------------------------------------------------------------------

General Safety Rules .........................................................................................................Page

01

Cover Page ........................................................................................................................Page

02

Set-Up Instructions ..................................................

..

...............

...

..

.........

..

.........................Page

03

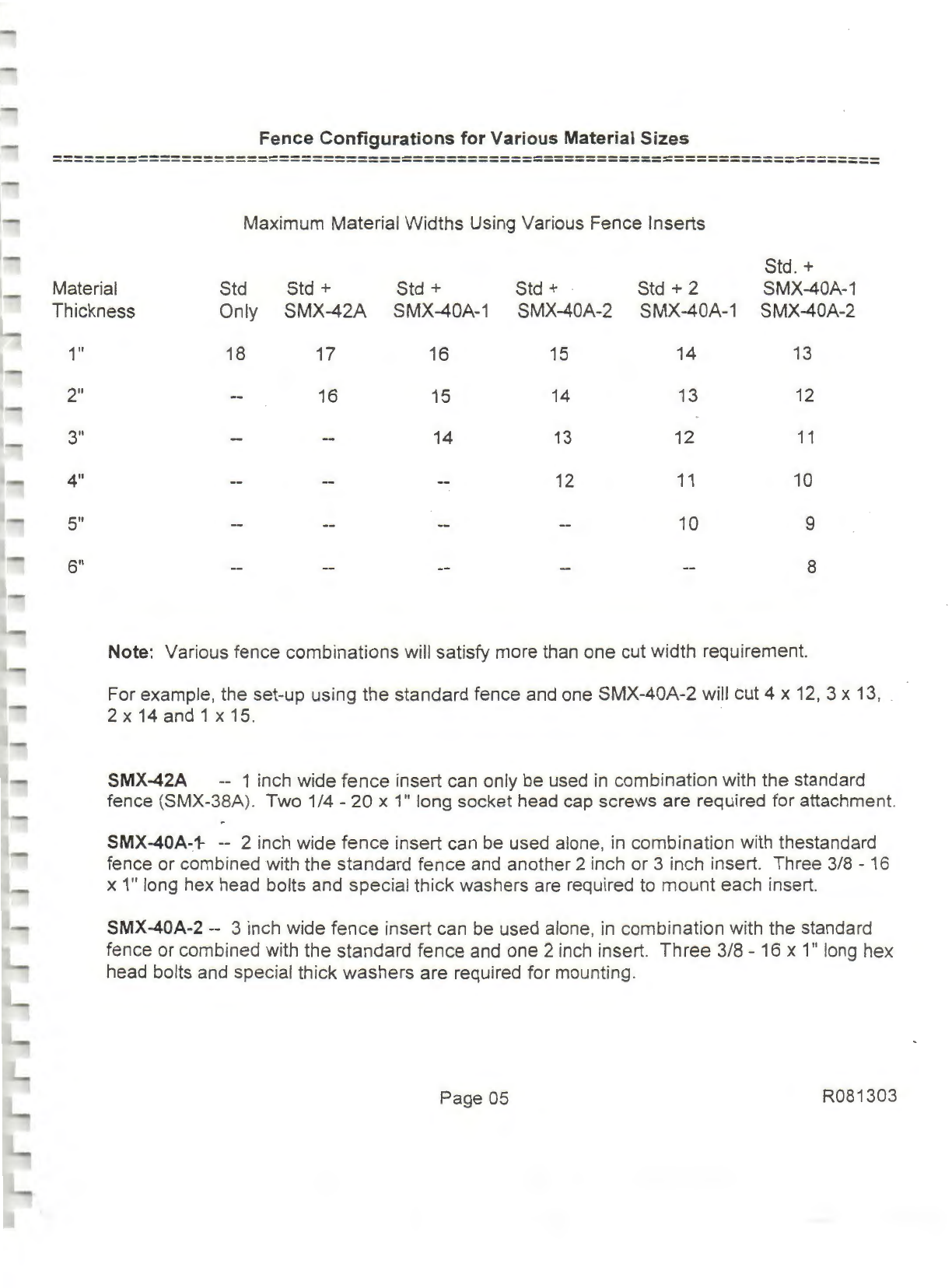

Fence Combination Guidelines

..

......................................

..

.........................................

...

....

Page

05

Trouble Shooting Guide .....................................................................................................Page

06

Adjustment

of

Valves .........................................................................................................Page

07

Instructions for Changing V-Belts .....

....

...........................

...

.............

..

...

...................

..

.....

...

Page

08

Suggested Maintenance ...............................

...

...

......

...

..

.................

..

...........................

..

....

Page

08

Warranty .................................................

..

.........

..

..................................

..

.....

..

.............

..

.

...

Page

09

Assembly Drawing .........

..

..................................................................................................Page 10

Diagram

of

Cylinder

...

.

...

.............

..

.....

..

.......

...

..

...

..

..........................................................

...

Page

12

Final Assembly Checklist

..

.........

..

......................

..

......................

...

......................

...

...

..

..

.....Page

13

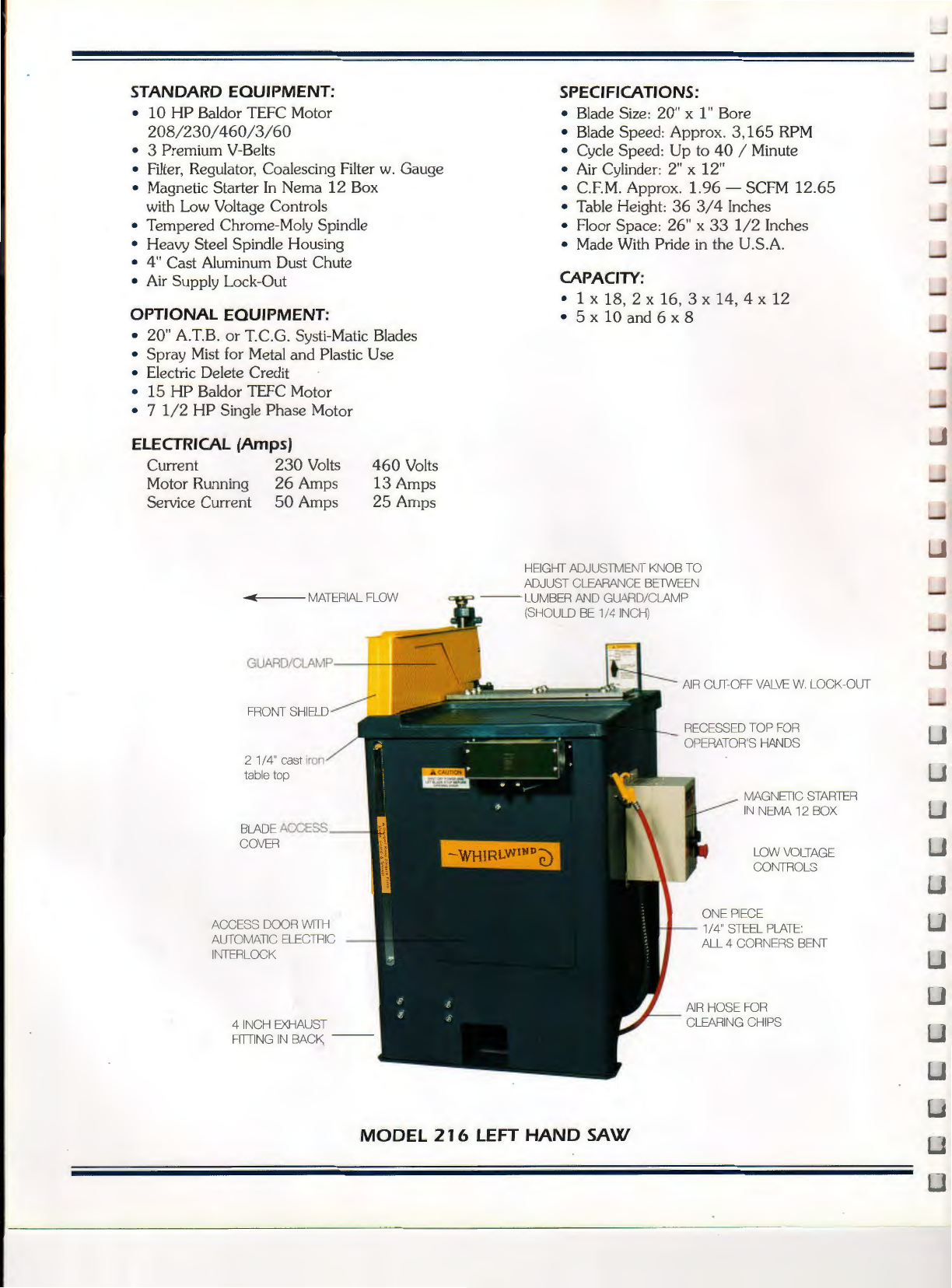

Brochure Model 216 Cut-Off

Saw

..................................

..

.....................................

...

..

...

......Page 15

Material Handling Equipment Flyer ........

...

..

...

...

...........................

..

..........

..

...

.......

..

...

.........Page

16

Safety Guide for-Carbide Tipped Blades ...............................................

..

.........................

..

Page

17

Specifications

on

Compressed

Air

Filter I Regulators ..................................

...

..

.....

...

..

...... Page

18

Specifications

on

Coalescing Filters ................................................................................. Page

19

Whirlwind Return Policy

.. ..

..

..........

..

...

..

......................................

..

.......

..

..

..

........:................Page 20

Double Palm Button Controls .......................

...

..

...

........

..

..........

...

....

..

...

...

..

......

..

................ Page

21

R081303