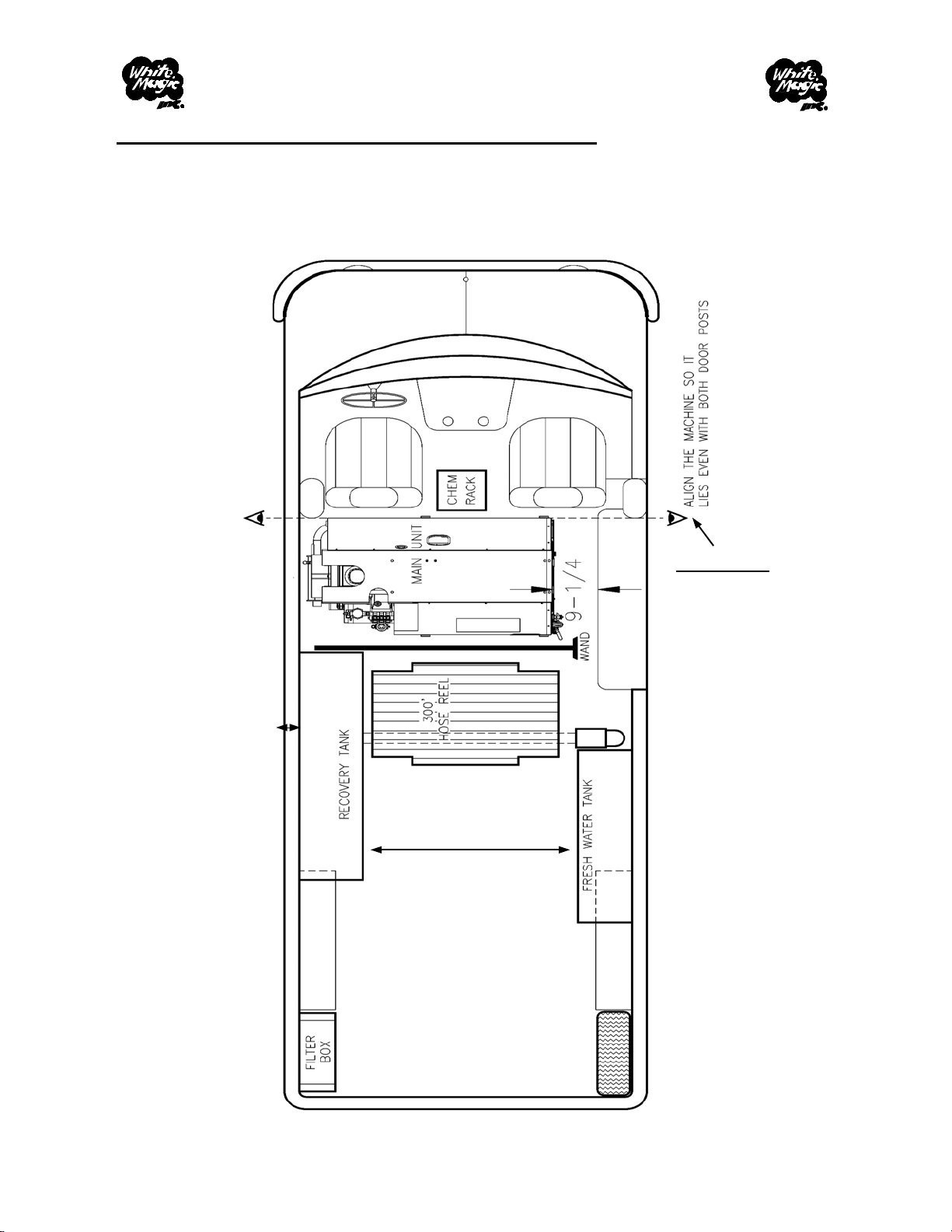

INSTALLING MACHINE INTO TRUCK (continued..)

12. Recovery Tank must be placed as close to the drivers side of van as possible

(especially for hose reel clearance.) It should be placed 2 1/2” from the

side cover of the machine.

13. Drill a 7/16” hole 3” from either end of tank mounting foot. (Always check

to make sure no damage will be done to critical van components before

drilling any holes.) Drop a bolt in each hole as it is drilled to prevent the

tanks from moving. Drill through the mount on the top of the tank. Use a

1-1/2” long 3/8-16 fully threaded bolt, 3/8” flat washer, and a special 1” x 2

1/2” long nut plate supplied for the top. This can be slid into one of the

holes of the frame of the van and held with fingers while starting the bolt.

Use two 3/8-16 x 2” long fully threaded bolts with 3/8” flat washers for the

bottom of the tank. Use fender washers, lock washers, and nuts underneath

the van. It should be noted that where ever a bolt goes through the heat

shielding under the van a hole saw should be used to cut out some shielding

to give access for the hardware. Do not tighten the nuts against the heat

shielding.

14. Water tank must be as close to the passenger side of the van as possible.

Clearance between water and recovery tanks MUST be at least 36” to allow

for placement of hose reel. Front to back placement of water tank is flexible

and depends on van length, customer preference, and accessories such as;

water reels, sprayer racks, ect.

15. Secure water tank in same manner as recovery tank.

16. Install filter box if so equipped.

a.) The filter box is bolted to the floor with (3) 3/8-16 fully

threaded bolts with fender and lock washers underneath. It is positioned in

the rear driver’s side corner of the van with the 3” input toward the van

wall.

b.) A piece of 3” hose is cut to 7’ to go from the input of the recovery tank

to the output of the filter box. It should be tie strapped to the ribs of the van

wall approximately 40” from the floor.

17. Install hose reel if so equipped. Note that the hose reel must be tilted back

to check for clearance before bolting bracket to the floor. The side of the

hose reel should be even with the edge of the recovery tank.

7