Contents

1. Overview...............................................................................................................................................................................................................4

1.1. Introduction of the machine....................................................................................................................................................................4

1.2. Introduction of the manufacturer.........................................................................................................................................................4

1.3. Packaging inspection....................................................................................................................................................................................4

2. Safety principles and instructions..........................................................................................................................................................5

2.1. Energy safety classification........................................................................................................................................................................6

2.2. Safety precautions...........................................................................................................................................................................................6

3. Machine general information..................................................................................................................................................................8

3.1. Machine characteristics................................................................................................................................................................................8

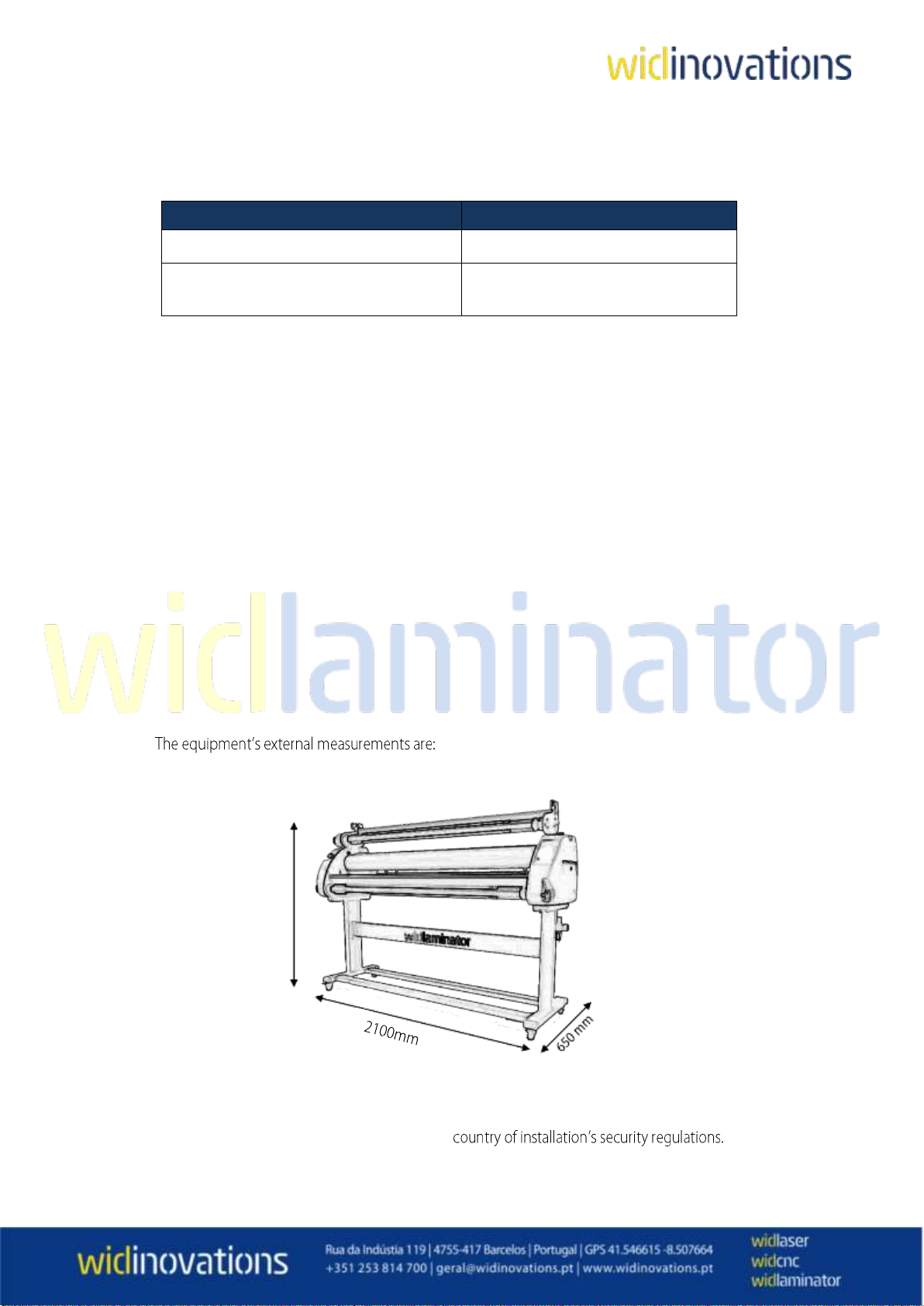

3.1.1. Physical dimensions.......................................................................................................................................................................................8

3.1.2. .......................................................................................................................................................................................9

3.1.3. Warning and information labels.............................................................................................................................................................9

3.1.4. Electrical specifications.............................................................................................................................................................................10

3.1.5. Component specifications......................................................................................................................................................................11

4. Installation and operation.......................................................................................................................................................................12

4.1. Unpacking the machine...........................................................................................................................................................................12

4.1.1. Packaging dimensions...............................................................................................................................................................................12

4.1.2. Unpacking the machine...........................................................................................................................................................................12

4.1.3. Components inside the packaging...................................................................................................................................................13

4.2. Assembling the widlaminator L300..................................................................................................................................................14

4.2.1. Assembling the support...........................................................................................................................................................................14

4.2.2. Placing the main body on the support structure.....................................................................................................................15

4.3. Air compressor...............................................................................................................................................................................................16

4.3.1. Assembling the air compressor...........................................................................................................................................................16

4.3.2. Connecting the compressor to the machine..............................................................................................................................17

4.4. Installing the heating elements...........................................................................................................................................................17

4.5. Installation environment..........................................................................................................................................................................20

4.6. Machine overview........................................................................................................................................................................................20

4.7. Starting the compressor...........................................................................................................................................................................22

4.8. Supplying the pneumatic system with oil....................................................................................................................................23

4.9. Placing the material support axes......................................................................................................................................................23

5. Working with the widlaminator L300..............................................................................................................................................24

5.1. Setting up the equipment......................................................................................................................................................................24

5.2. Turning ON theequipmentand beginning work....................................................................................................................29

5.3. Turning OFF theequipment..................................................................................................................................................................29

6. Maintenance....................................................................................................................................................................................................30