Maintenance & Troubleshooting

Lamp Replacement

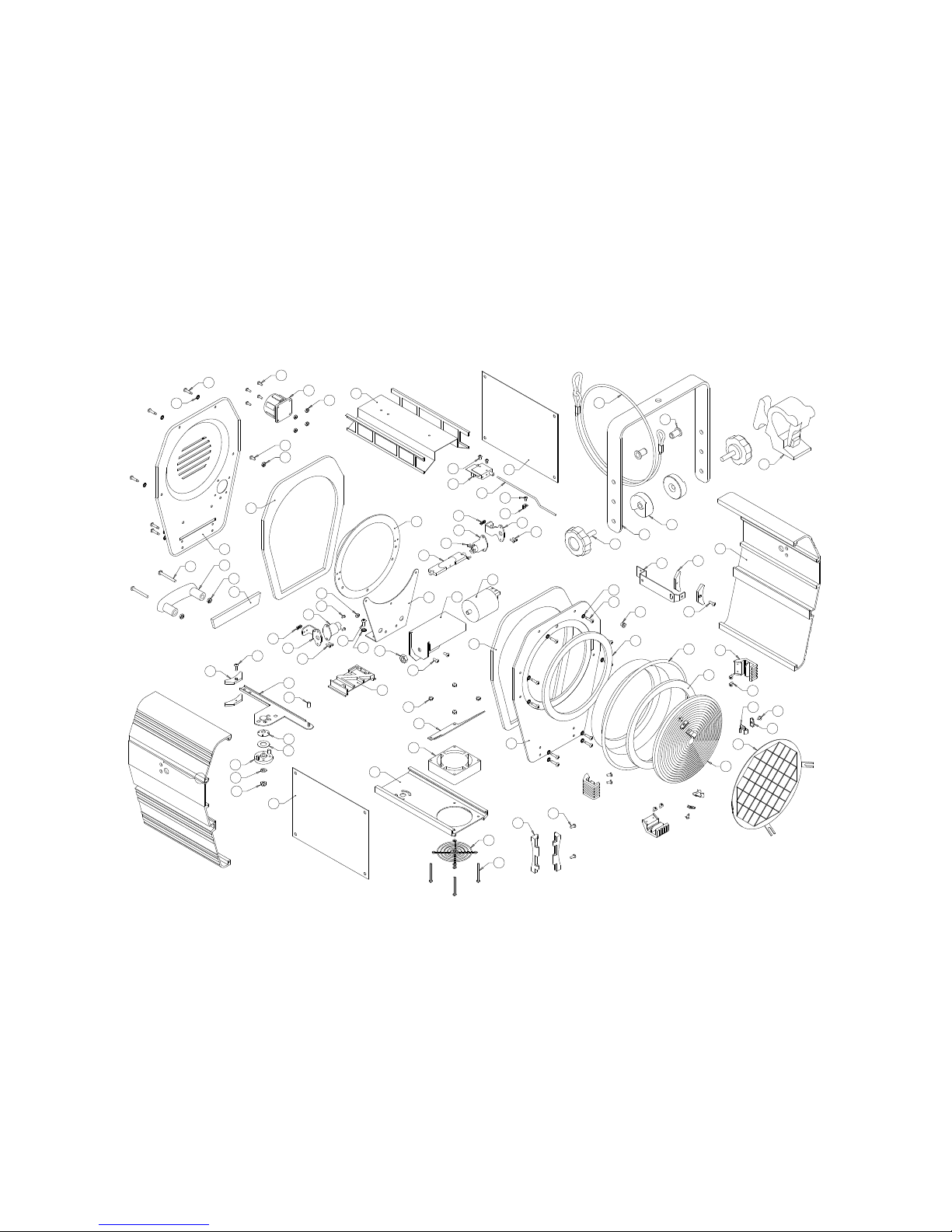

Unplug the fixture. Remove any accessories from the front. Set the focus control to the F position Make sure the

fixture is cool to the touch before opening the lens door. Release the lens door latch by pulling the latch away

from the door. Swing the front lens door open. Grasp the lamp in the center remove it by pushing it gently to one

side sliding the other end forward. Reverse this procedure to install the new lamp. After installing gently rock the

new lamp back and forth to insure the depressions on the ends of the lamp are firmly seated on the posts of the

sockets. If the lamp is not firmly seated arcing could occur melting both the socket and lamp. Care should be

taken not to touch the new lamp directly use a cloth or glove when handling if you have touched the lamp it must

be cleaned with alcohol to remove any oils and fingerprints prior to striking. For maximum UV-A output always

use Wildfire IronArc®lamps, and change the lamp in your fixture every 1000 hours.

Cleaning

For best performance, the reflector, lamp and filter lens should be kept free of dirt and dust. At no time should

any cleaning chemicals or abrasives be used to clean any part of the fixture. Do not spray or apply any liquid

directly to any part of the fixture. Always unplug the unit. before cleaning. For normal cleaning, a dry soft cloth

should be used to wipe any surface free from dust and light dirt. Cleaning the reflector will require that the lamp

be removed. Remove the lamp by following the instructions listed under lamp replacement above. Once the

lamp has been removed, gently wipe off the reflector using a soft dry cloth. In the event the reflector is heavily

soiled, lightly dampen the cloth with a mild window cleaning agent and wipe clean. The filter lens can be cleaned

in the same manner. The lamp should be cleaned with alcohol only.

Troubleshooting

Red LED is flashing display reads 1000 to 9999: -- The lamp has reached the end of its life, reducing UV

output considerably. Replace the lamp in the fixture.

Red LED is on and the display is flashing “O F F”: -- The fixture is attempting to strike the lamp however the

lamp has either not cooled enough to strike or the lamp is bad. Wait 5 minutes for the lamp to completely cool. If

it still won’t strike, replace the lamp.

Green LED is flashing and the display reads “0 0 0”: -- The fixture is set for a valid DMX address however

DMX signal is not being received. Check DMX settings on control board or software as well as cabling to the

fixture.

Display and LED’s are not lit: -- Fixture is operating in dark mode, press the select button to reactivate the

display and LED’s.

The fixture will not strike: – Check to make sure there is power to the ballast. Make sure the power/breaker

switch on the ballast has not been tripped. Unplug the ballast. Check to see if the fixture has a lamp installed

and that it is seated properly in the sockets (see lamp replacement above). Check to see if the safety cutoff

switch is making contact by closing the lens cover and listening for a clicking sound. If the fixture still is not

striking try replacing the lamp. If you have checked all of the above and the fixture still won’t strike contact

Wildfire technical support at (310) 645-7787 or your local distributor.

The effect is not working anymore: – Try changing the lamp. The lamp in your Wildfire fixture is rated at 1000

hours. This does not necessarily mean that the lamp will “burn out” or not light after 1000 hours it may continue

to burn for a much longer period of time however the amount of UV it produces will be reduced considerably

causing the effect to appear as though it isn’t working. Wildfire recommends for maximum effect to change the

lamp every 1000 hours.

7