©| Aerservice S.r.l. | 2019 all rights reserved Reproduction, in whole or in part, is not allowed.

Analytical index of the operating and maintenance manual

INDEX ................................................................................................................................... 2

Analytical index of the operating and maintenance manual .................................................... 2

Purpose of the operating and maintenance manual ....................................................... 3

Storage of the instruction manual .................................................................................... 4

Updating of the Instruction Manual .................................................................................. 4

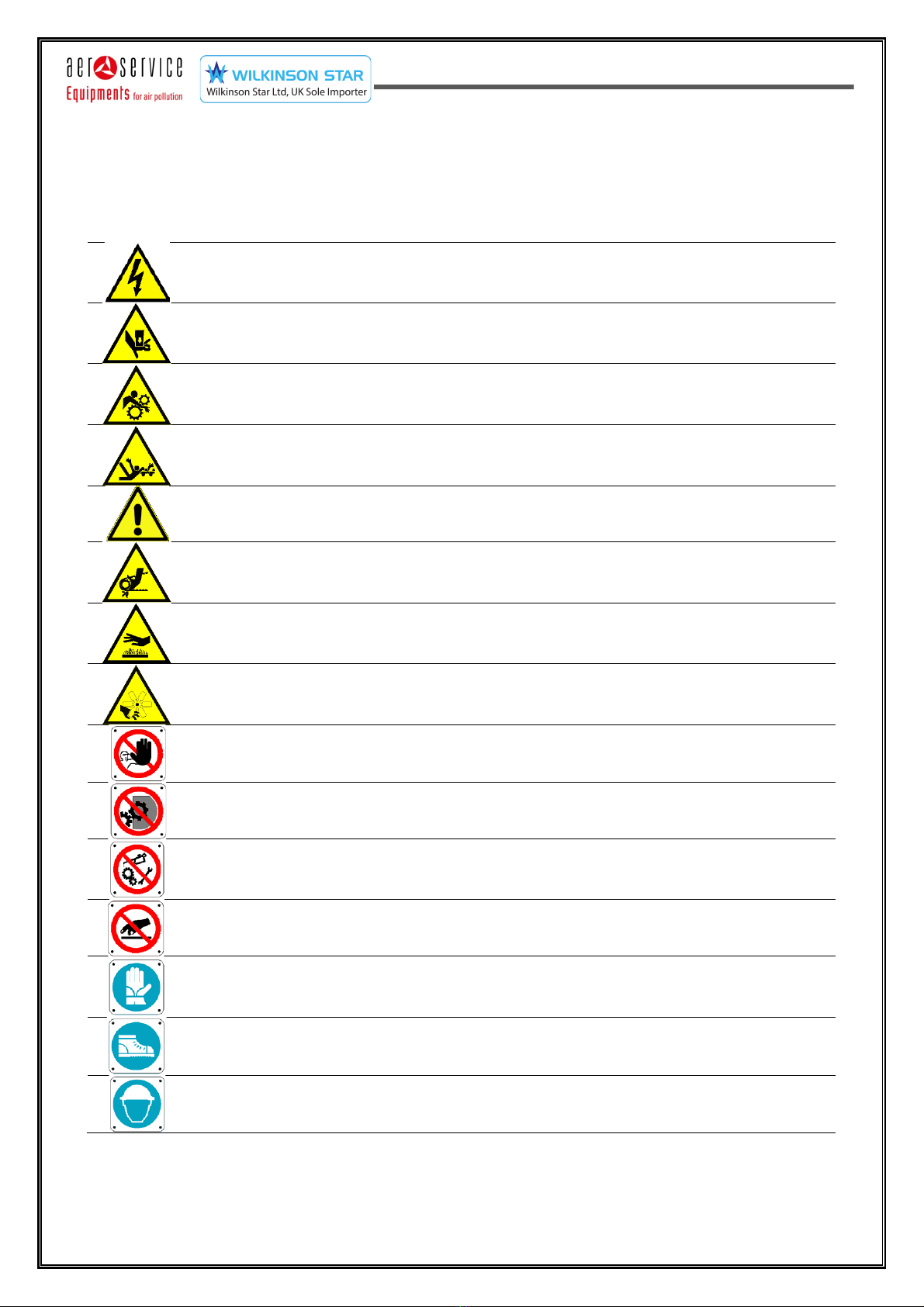

Glossary and pictograms .................................................................................................. 4

Manufacturer’s identification data .................................................................................... 7

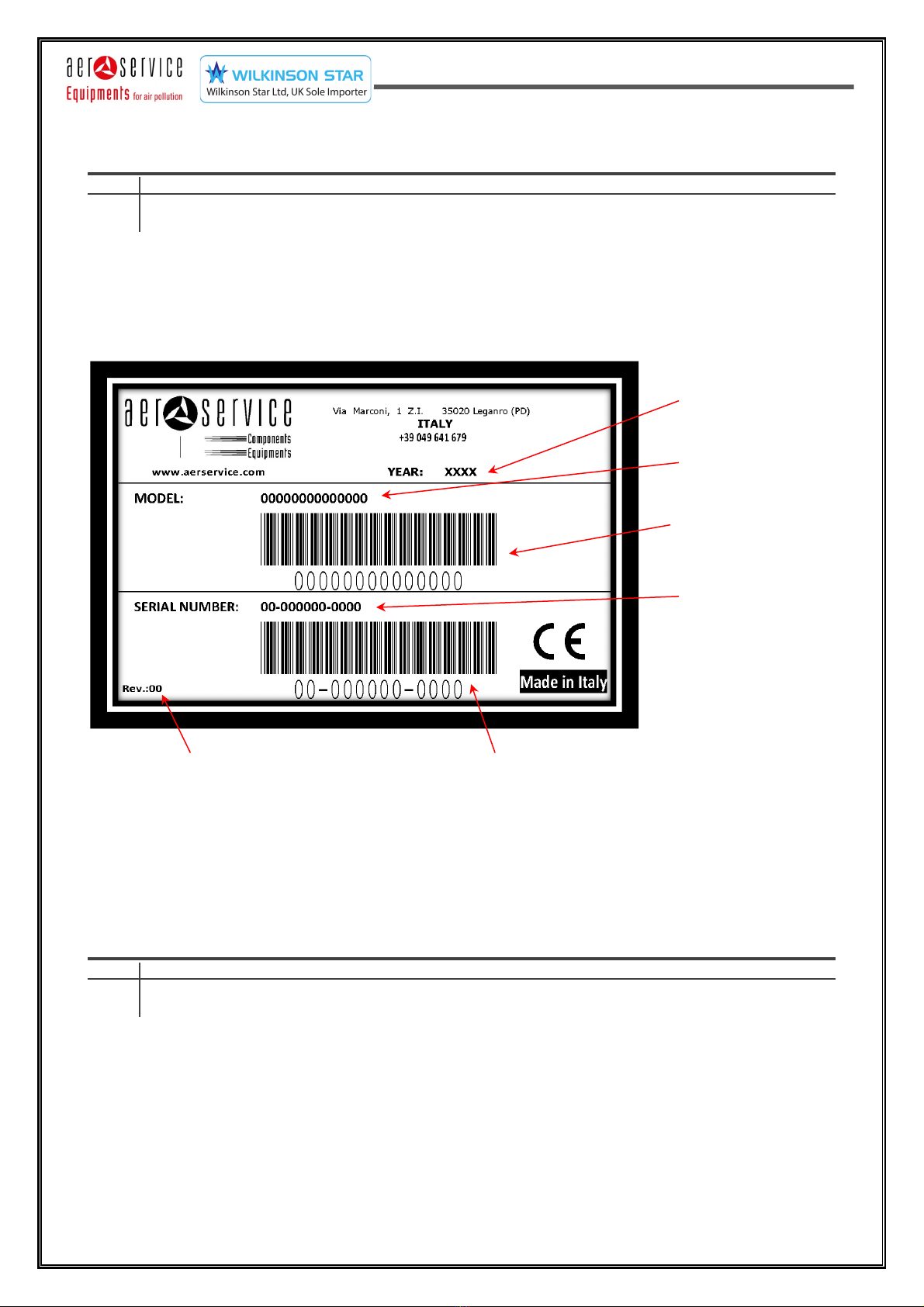

Machine identification and data plates ............................................................................. 8

Declarations ........................................................................................................................ 8

Warranty activation .......................................................................................................... 10

USE AND GENERAL CHARACTERISTICS ..................................................................... 11

FEATURES ........................................................................................................................ 11

Technical data ............................................................................................................................ 13

INSTALLATION, COMMISSIONING AND START-UP ..................................................... 14

FUNCTIONING ................................................................................................................... 14

Normal use .................................................................................................................................. 14

Most frequent problems: causes and remedies ...................................................................... 15

Risks and emergencies ............................................................................................................. 15

MAINTENANCE ................................................................................................................. 16

F-Tech Pocket - Cleaning and change of parts ....................................................................... 16

Inspections ................................................................................................................................. 17

DECOMMISSIONING ......................................................................................................... 18

Dismantling and demolition ...................................................................................................... 18

WIRING .............................................................................................................................. 18

F-Tech Pocket ............................................................................................................................. 18

OPERATOR’S NOTES ...................................................................................................... 19

Details of maintenance operations ........................................................................................... 19