EN

10

10

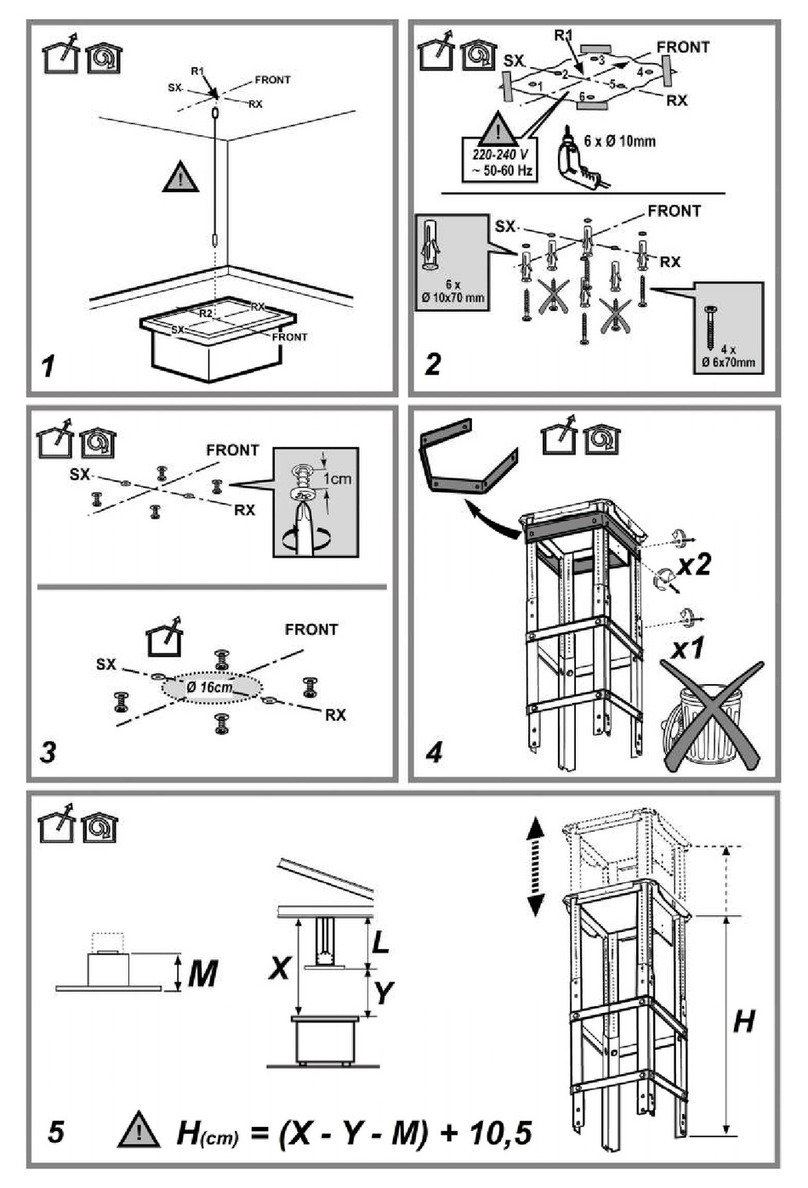

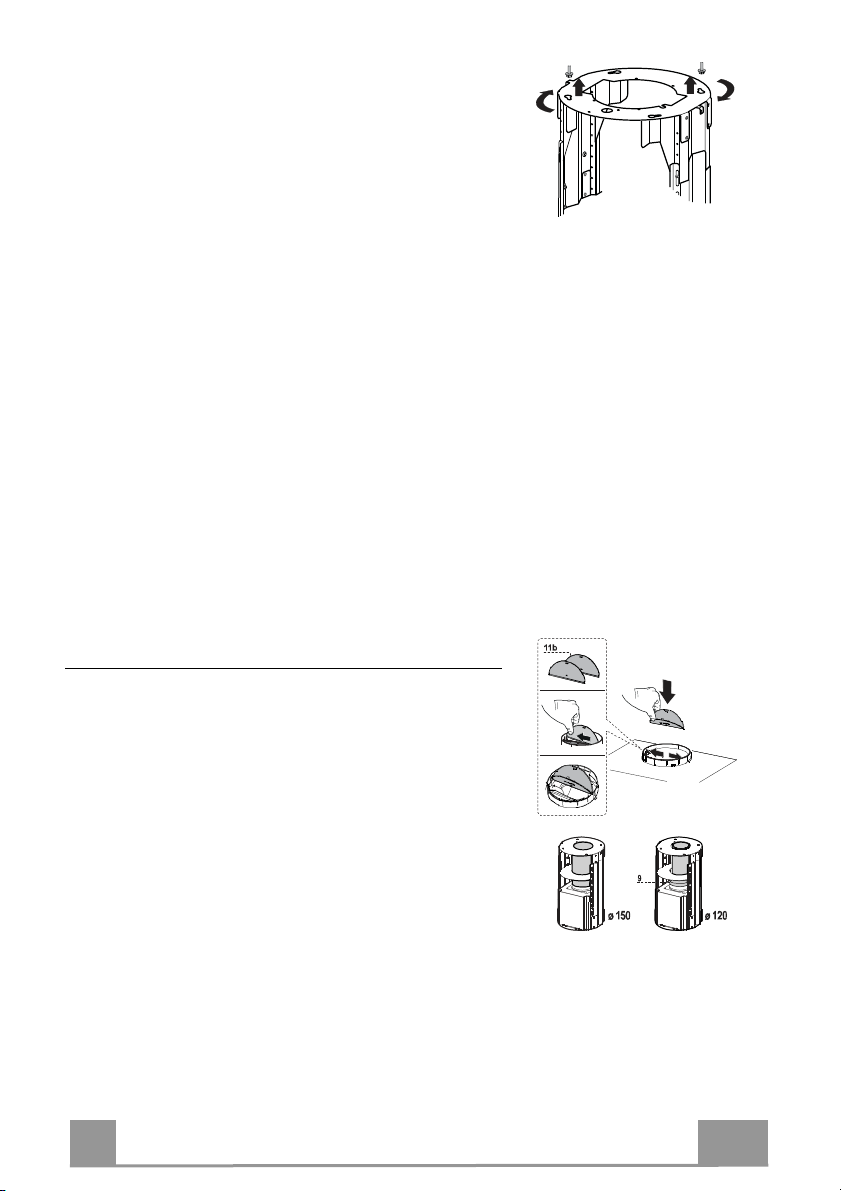

FIXING THE FRAME

• Lift the frame up, making sure that the index over the

frame plate is turned forwards.

• Fit the frame slots onto the two screws inserted in the

ceiling as above, and turn until reaching the centre of the

adjustment slot.

• Tighten the two screws and fasten the other two screws

provided; before locking the screws completely, it is

possible to adjust the frame by turning it, making sure

that the screws do not come out of their housing in the

adjustment slot.

• The Frame must be securely fastened so as to support

both the weight of the Hood and the stress caused by oc-

casional axial pressure against the fitted Appliance. Af-

ter fixing, make sure that the base is stable even when

the Frame is subjected to lateral stress.

• If the Ceiling is not strong enough in the area where the

hood is to be fixed, the Installer must strengthen the area

using suitable plates and counterplates anchored to re-

sistant structures.

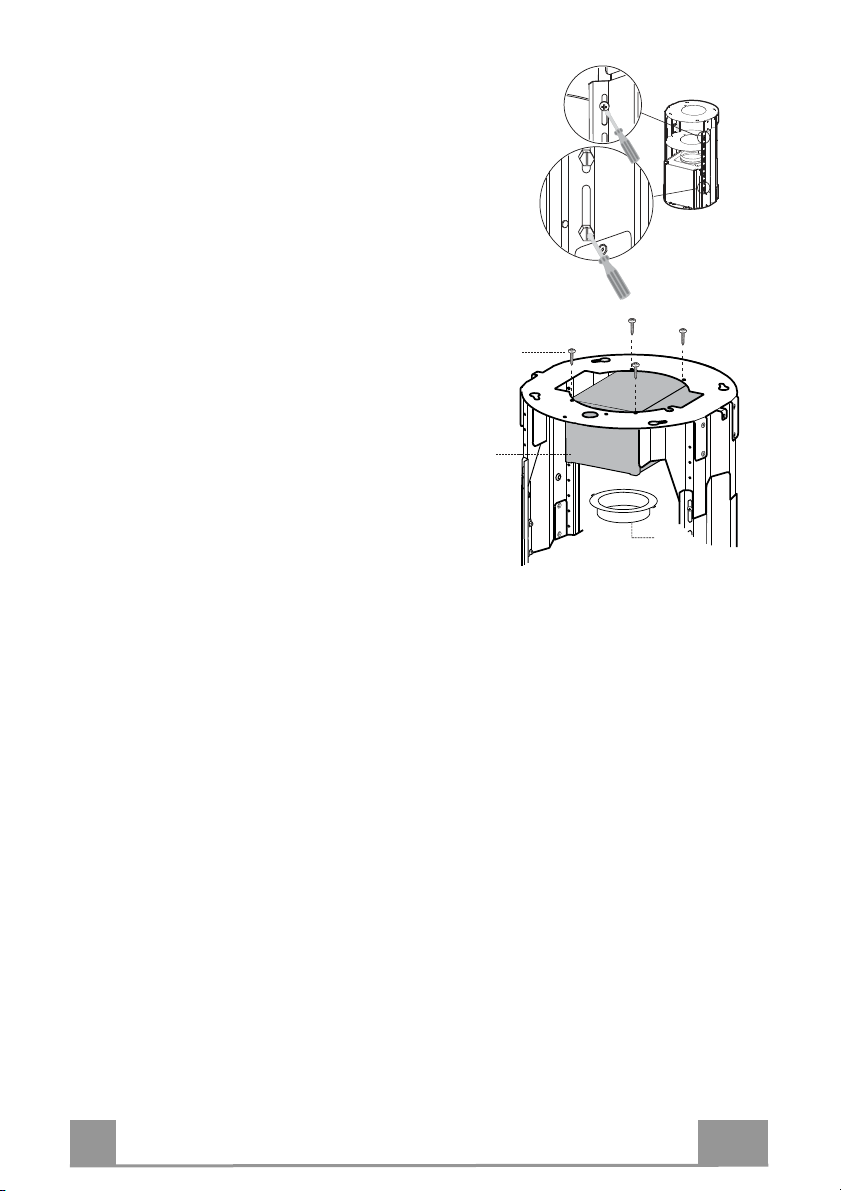

Conn ctions

AIR OUTLET DUCTING VERSION

When installing the Ducting version, join the Hood to the

outlet duct using a rigid or flexible pipe ø150 or 120 mm,

selection of which is at the discretion of the installation

technician.

• Insert flaps 11b on the Hood Canopy Outlet.

Connecting the ø 150 pipe

• Fasten the pipe using suitable pipe clamps. The materials

required to do so are not provided.

Connecting the ø 120 pipe

• To connect using a ø120 mm pipe, insert the reduction

Flange 9onto the Hood Canopy Outlet.

• Fasten the pipe using suitable pipe clamps. The materials

required to do so are not provided.

• In both cases, any Activated Charcoal Filters must be

removed.