Contents

1. Safety and Health Precautions ...............................................................................................1

1.1 CAUTION.......................................................................................................................... 1

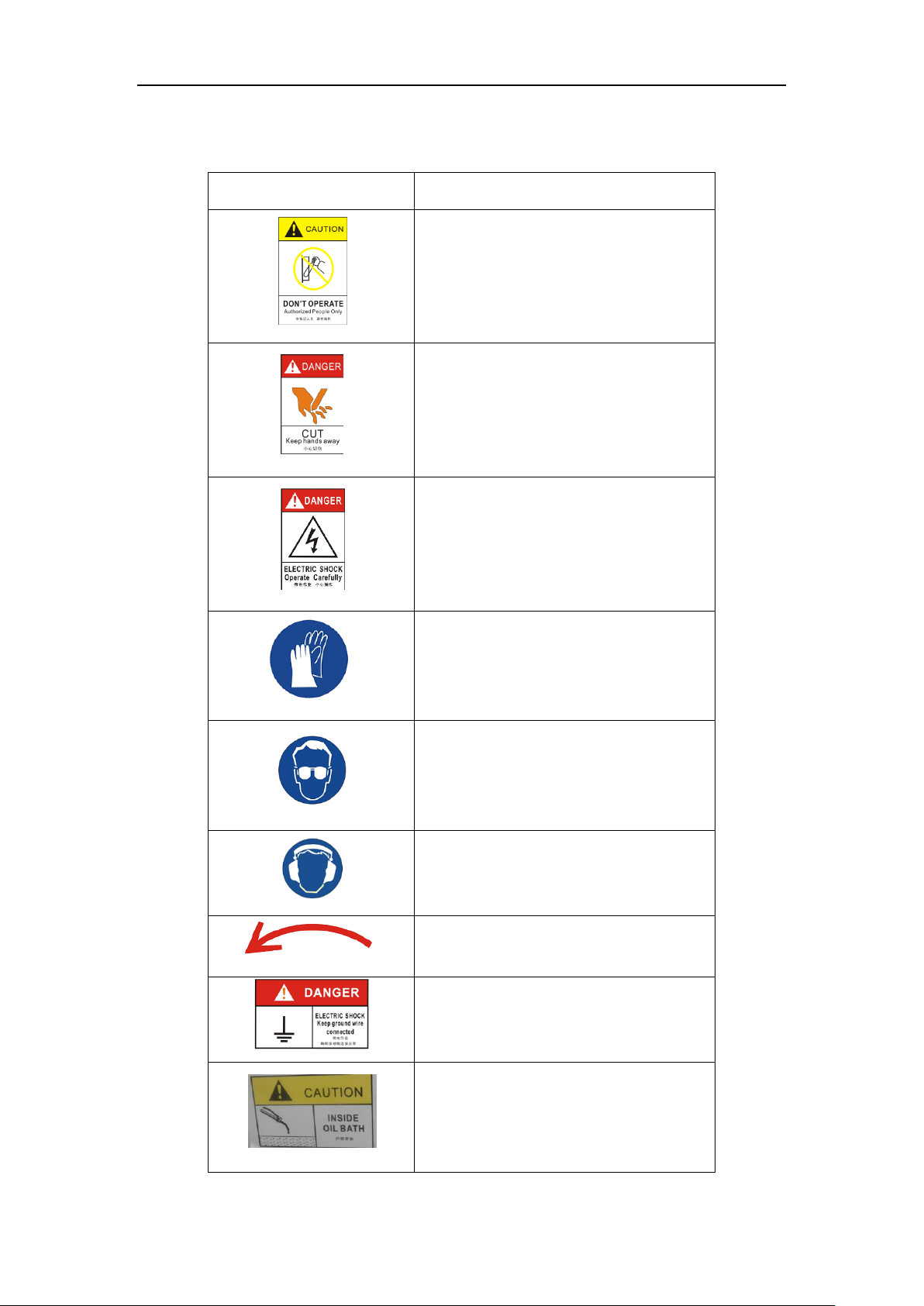

1.2 Graphic Symbols.............................................................................................................. 2

1.3 Technical Data ................................................................................................................. 3

2. Installation..............................................................................................................................4

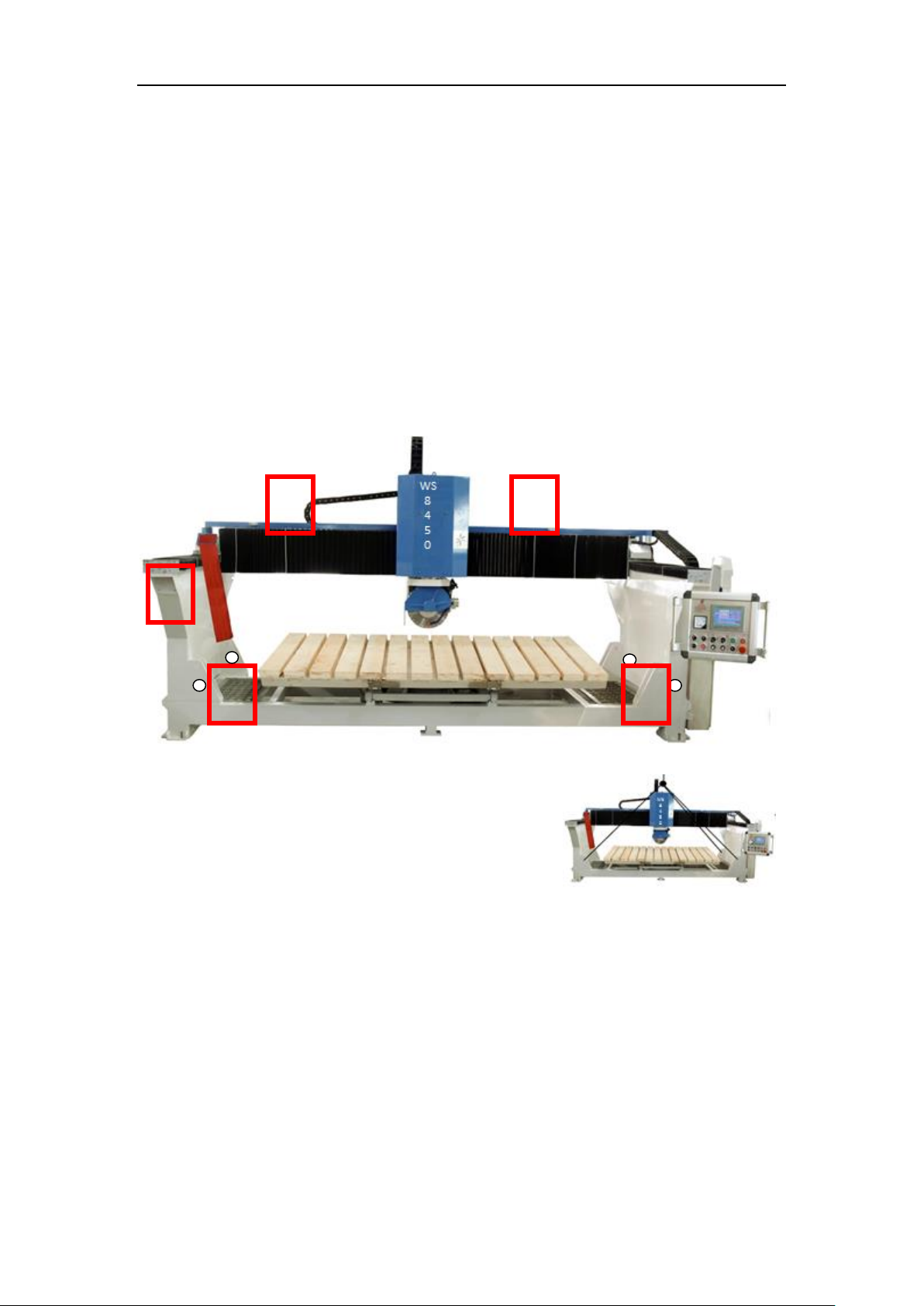

2.1 Lifting and Moving Machine............................................................................................ 4

2.2 Machine Leveling............................................................................................................. 4

2.3 Bridge Installation............................................................................................................ 6

2.4 Lubrification.......................................................................Error! Bookmark not defined.

3. Operation ...............................................................................................................................9

3.1 Axis Reference ................................................................................................................. 9

3.2 Turning on the Machine .................................................................................................. 9

3.3 Panel.............................................................................................................................. 10

3.4 HMI ................................................................................................................................ 12

3.5 Example ......................................................................................................................... 19

4. Adjusts and Maintenance.................................................................................................... 30

4.1 Hydraulic Adjust. ........................................................................................................... 30

4.2 Maintenance.................................................................................................................. 31

5. Attachment.......................................................................................................................... 32

5.1 Parameter...................................................................................................................... 32

5.2 Input/Output ................................................................................................................. 33

5.3 Server Parameter........................................................................................................... 35

5.4 Hydraulic System ........................................................................................................... 36