INSTALLATION

4CVap®Cook & Hold

WARNING: Daily cleaning required or warranty will be voided. See Daily Cleaning instructions in this manual

SHIPPING DAMAGE

All equipment should be thoroughly examined for shipping damage before, during

and after unloading. It has been carefully inspected at our factory and the carrier

has assumed responsibility for its safe arrival. If the equipment is damaged,

either apparent or concealed, a claim must be made to the carrier.

APPARENT LOSS OR DAMAGE

If there is any obvious loss or damage, it must be noted on the freight bill or express

receipt and signed by the carrier’s agent; otherwise, the carrier may refuse the

claim. The carrier will supply the necessary forms.

CONCEALED LOSS OR DAMAGE

When loss or damage is not apparent until after the equipment is uncrated, a claim

for concealed damage must be made. Upon discovering damage, make a request

in writing to the carrier for inspection within 15 days, and retain all packing. The

carrier will supply an inspection report and the required claim forms.

PHYSICAL

Casters are non-marking; back casters are non-locking, front are locking.

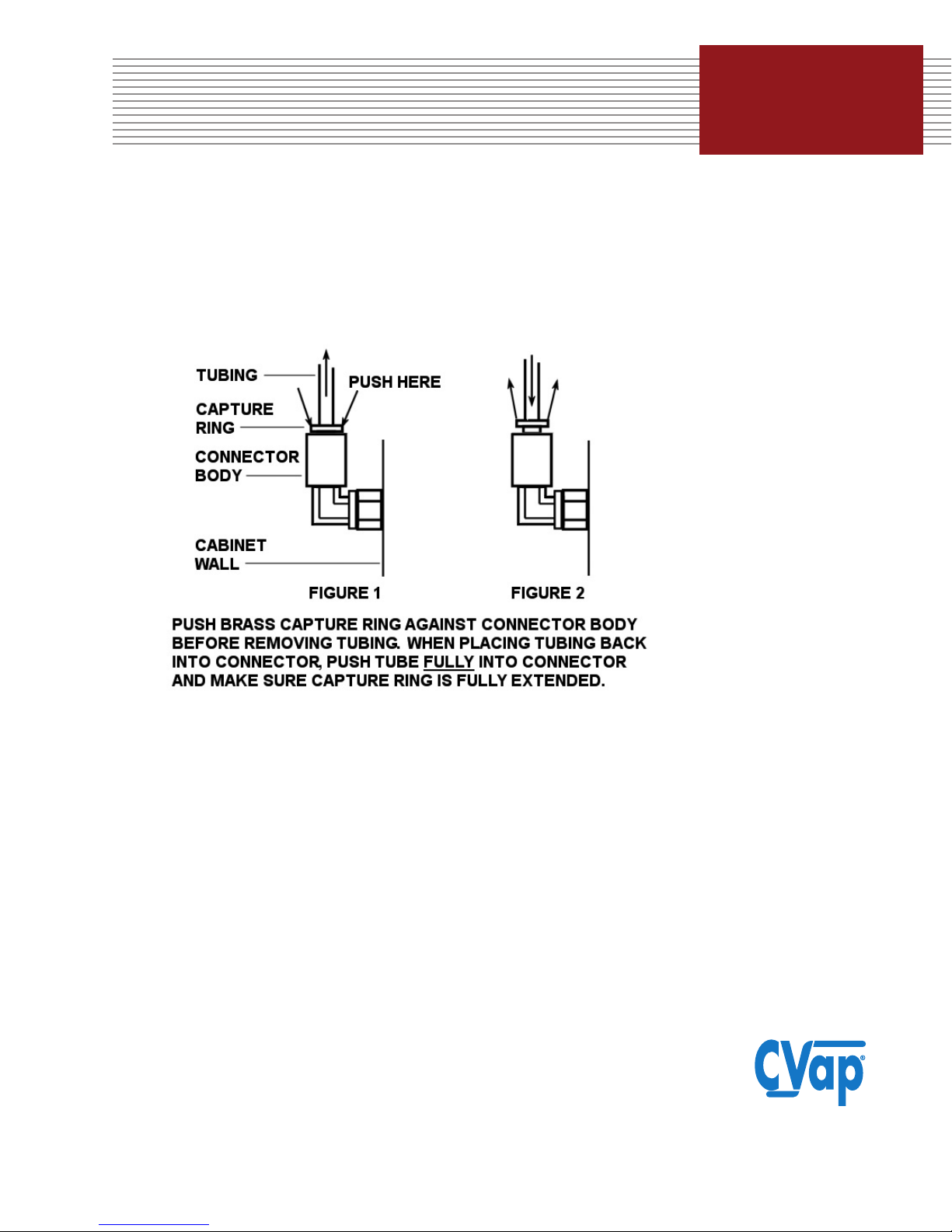

WATER SUPPLY

The evaporator of this appliance must be filled each day and during use from a

potable water supply. In that regard, an automatic fill system is provided that is to

be connected to a potable water supply. Hardware is included with each unit to

allow connection to a copper line.

NOTE: When installing the automatic water fill plumbing, make sure to remove the

plastic plug from the water inlet connector before hooking up the water line.

If plastic or galvanized piping is encountered, a licensed plumber should be called

to make the installation. This equipment is to be installed to comply with the

applicable federal, state, or local plumbing codes.

As water evaporates from the dual heat surface of the evaporator, any minerals in

the water will deposit on those surfaces. Consequently, the mineral deposits on the

surfaces inhibit the ability to transfer heat through the deposits, and the stainless

steel on which they are deposited can be degraded and destroyed. The first

protection against this is the daily cleaning procedure. It is also recommended that

your supplier of potable water be contacted for advice to minimize mineral deposit

build-up.

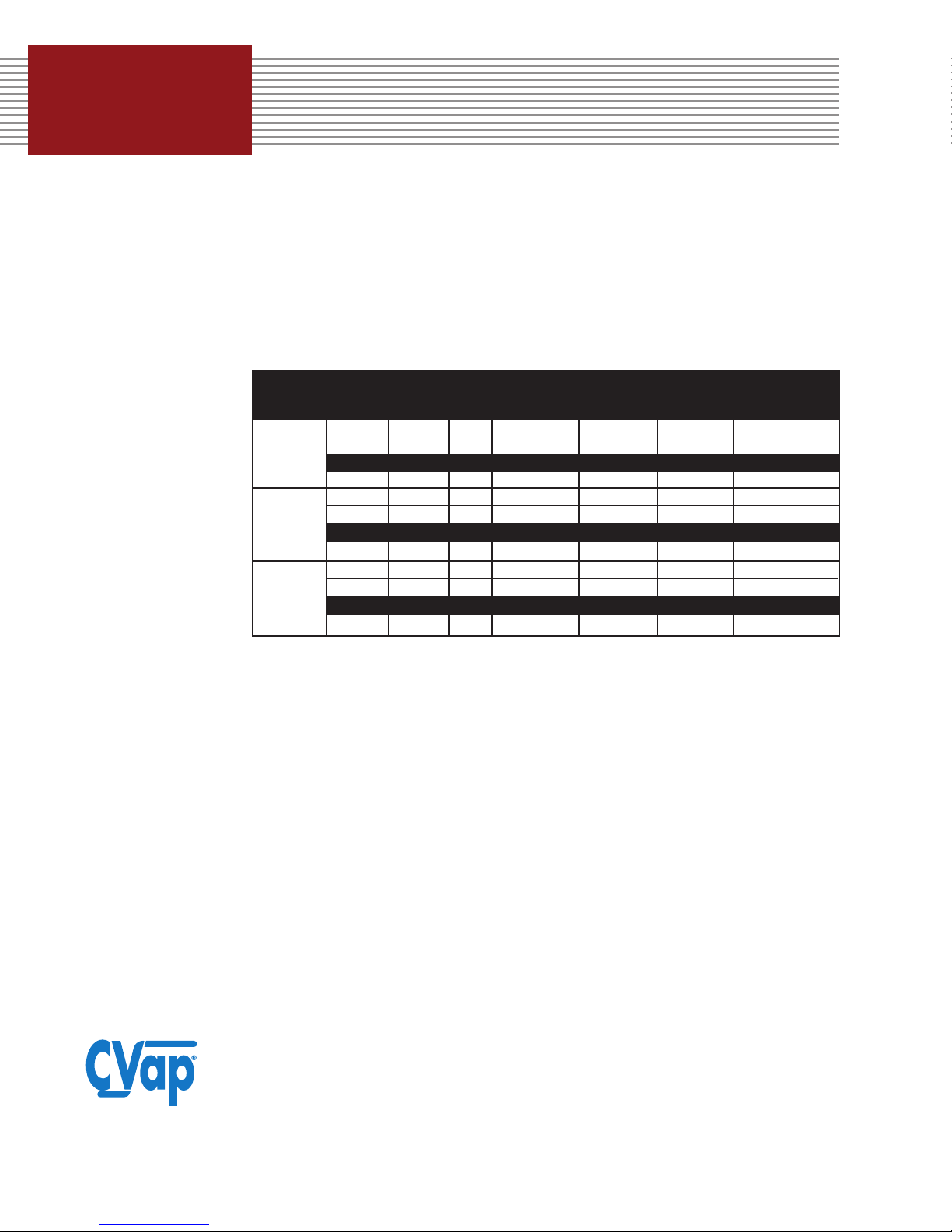

Model Height with 3” Width Depth Weight

Caster (IN/MM) (IN/MM) (IN/MM) (LBS/KG)

CAC503 36.1/917 19.9/505 27.1/688 145/66

CAC507 36.2/919 27.6/701 34.5/876 215/98

CAC509 43.2/1097 27.6/701 34.5/876 235/107