Wooden Gear Clocks UK

316 Pickering Road, Hull, East Yorkshire, UK Tel 01482 509277

http://wooden-gear-clocks.co.uk/

The spacers can be inserted onto to the 3mm mandrill supplied and sanded using a battery drill and

abrasive paper. The spacers should be trial fitted to the shafts. They should be tight but not so tight that

they cannot be moved with finger pressure. If they are too tight then enlarge the hole with the 3mm drill.

Twist the spacers onto the drill in a counter clockwise direction so that the faces are not split. If you drill

into the in a conventional direction the faces will be damaged. You can now enlarge the hole by holding

the spacer and sliding the drill bit up and down.

Brass shafts:

The shafts should be cut to the required length (5 in all). I am unable to get brass rod that fits with the

required tolerances to the bearings. The shafts should be a smooth sliding fit in the bearings. This

makes subsequent assembly much easier and prevents damage to the parts.

Put a shaft into the battery drill and sand with 120 grade abrasive for about 5 seconds, moving the

abrasive up and down the shaft. Finish with 180 grade and trial fit to the bearing. Repeat until the

required fit is achieved. Repeat for the other end.

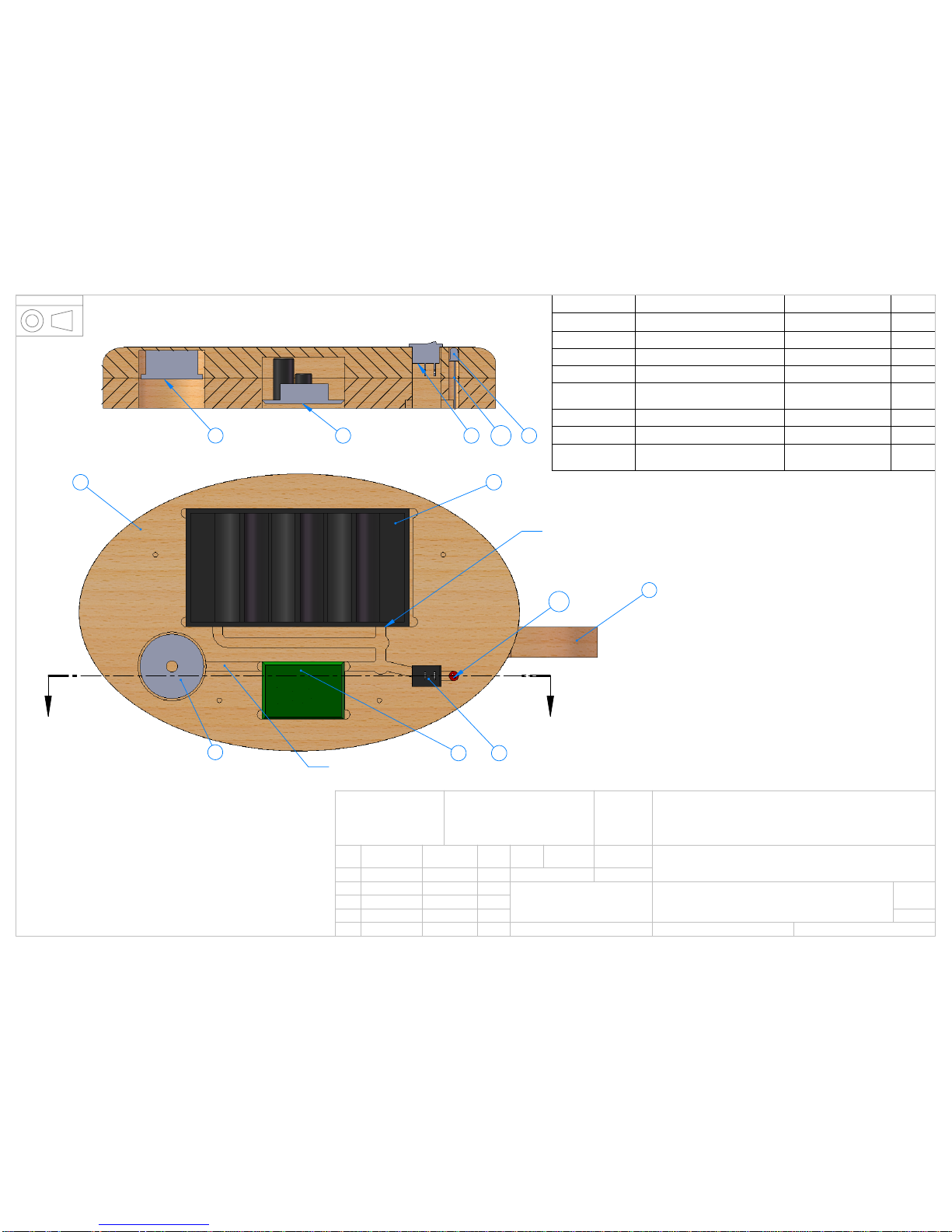

3. Drawing Clockerel-0002

When the desired finish has been achieved the bearings can be fitted into the holes as shown in section

C-C. The bearings should be pressed partly into the holes using finger pressure. If they are too tight then

lightly sand the inside of the holes until the desired fit is achieved. Push the bearings fully home with the

flat side of a 25mm wide steel rule or similar. This ensures that the bearings are square and flush with

the face of the frame.

Stick the pads to the base (ensure it’s the right side) and temporarily attach the base cover to the base

with the 4 screws provided. Carry out instruction 4 before gluing the frame to the base.

Ensure that the hole for the frame is clear and temporarily fit the frame to the base. The hole in the base

is 6mm longer than the adjoining piece of the frame. Therefore the frame requires fitting central in the

hole. Check that the pendulum bearing is approximately 139mm from the base when measured at 90

degrees from the base.

When happy a small amount of epoxy can be put around the hole and the parts fixed permanently.

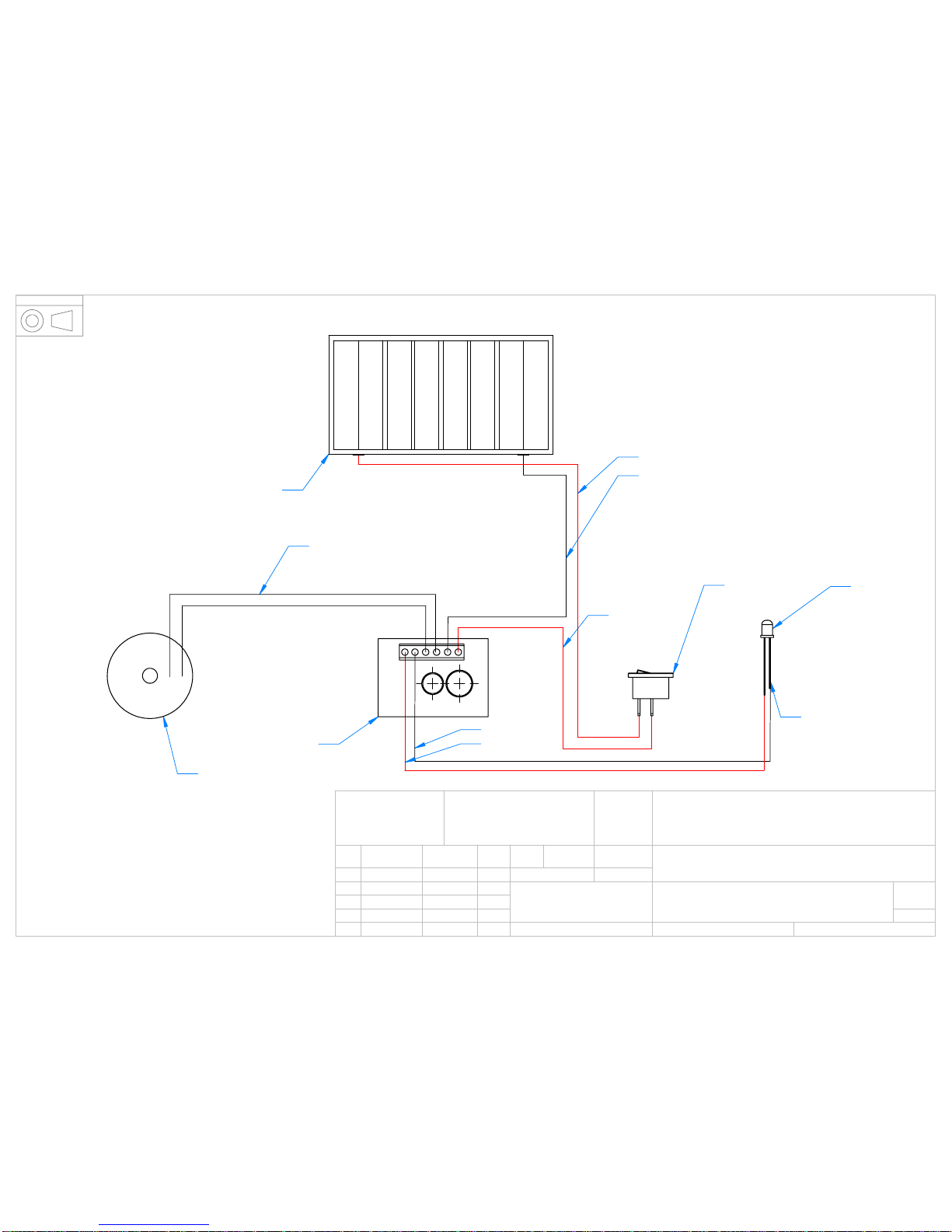

4. Clockerel-0003/0004

The electrical components should now be installed. Remove the base cover and place the base inverted

onto the work surface. Cover the work surface with a towel or similar to protect the base finish and

switch after installation

Cut 1 piece of red wire 165mm long and 1 piece 250mm long. Solder these to the switch terminals and

install into the frame with the wires passing through the hole.

Cut 1 piece of black wire 125mm long and solder this to the negative terminal of the battery box. Ensure

that the wire orientation is such that the wire will be pointing the correct direction when the battery box is

installed.

Cut 1 piece of red wire 100mm long and 1 piece of black wire 100mm long. Solder the red wire to the

longer terminal of the LED and the black wire to the shorter terminal. Push a piece of the heat shrink

material over one of the terminals to prevent a short circuit between the terminals. Shrink this on with a

cigarette lighter, being careful not to burn it.

Insert the switch into the base. Solder the longer wire to the battery box positive terminal ensuring the

correct orientation.

The battery box can now be fitted.

Insert the LED into the hole in the base. This hole may require cleaning as glue can enter it during the

base assembly. Place the LED to the depth you prefer.

Place the coil into the frame recess paying attention to the orientation shown in drawing Clockerel-0004.

Burn or sand the lacquer from the coil terminals and connect these to the 2 center terminals of the circuit

board. Connect the LED wires as shown in the wiring schematic. Connect the black wire from the battery

box and the red wire from the switch to the circuit board as shown. Be careful to get these the correct

way round. The circuit board is not polarity protected due to resistance issues. Incorrect connection

would damage the board.