6

INTRODUCTION

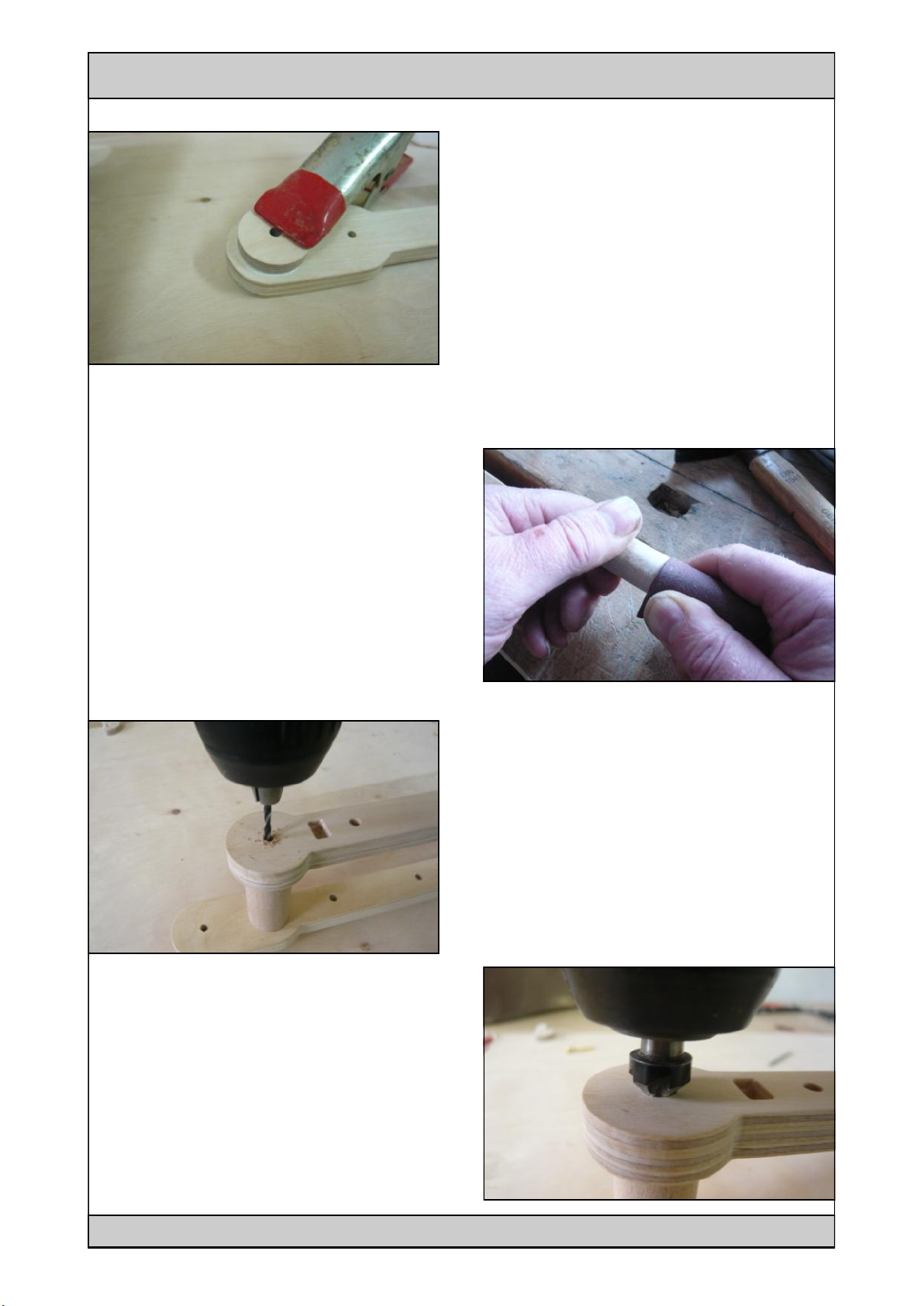

Spring Clamps

You need a minimum of 2, just make sure they have jaws long

enough to span 6cm-2¼.

Screw driver

Standard slot-head medium screw driver.

Needle Files

Not an absolute must, but will be required if you do not have a

belt or disc sander.

Lead Shot

Your lead shot should be of smaller diameter, if the diameter is

too large you will not be able to pack in enough.

Treating

Obviously the treating of your clock is very much a question of

personal preference, you could even make your finish match your

curtains/drapes. You may even have a pet finish, which is why I

will just mention the finished I used.

I used an acrylic, teak coloured, water based varnish, with a

matte finish. The advantages of acrylic are its quick drying time

(hand dry within 5 mins), lack of fumes and the brush can be

cleaned with water.

I sanded all the parts smooth with 180 grade sandpaper, then ap-

plied the first coat. As water will raise the grain, I pretty

much sanded all the varnish off until I got a smooth surface.

Then repeated the process, it will take about 2-3 coats before

the surface remains smooth. It took about 6 layers until I got a

deep lustre with even colouring. And you would have to look

closely to see that it is not solid wood.

I treated just the frame, pendulum bob and hands. Be wary of

treating the cogs as a varnish on the teeth connecting surfaces

will eventually wear off and literally clog the works, if you

want to varnish, mask off the teeth surfaces with masking tape,

and remove any “creeped” in varnish. I never treat the cogs, as I

think they look best untreated and with birch the yellowing is

minimal.

If you do decide to treat the frame, remember to remove the fin-

ish from the inside of frame arbor holes, as this could stop your

clock from working. You could use the supplied ⌀4.2mm drill bit.