14 15

3730 E. SOUTHERN AVE., PHOENIX, AZ 85040 | USA 800.778.8779 | WORKHORSEPRODUCTS.COM

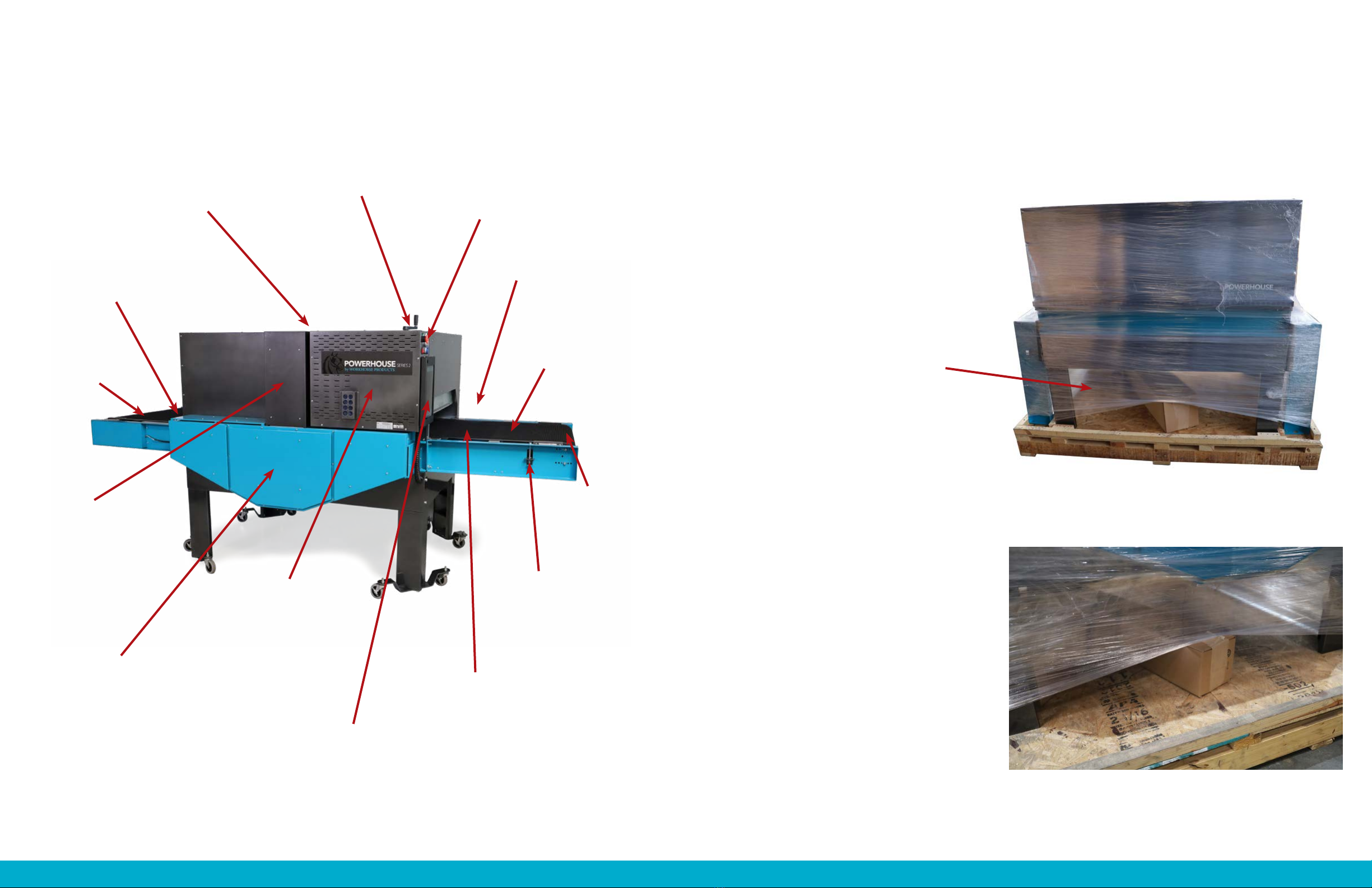

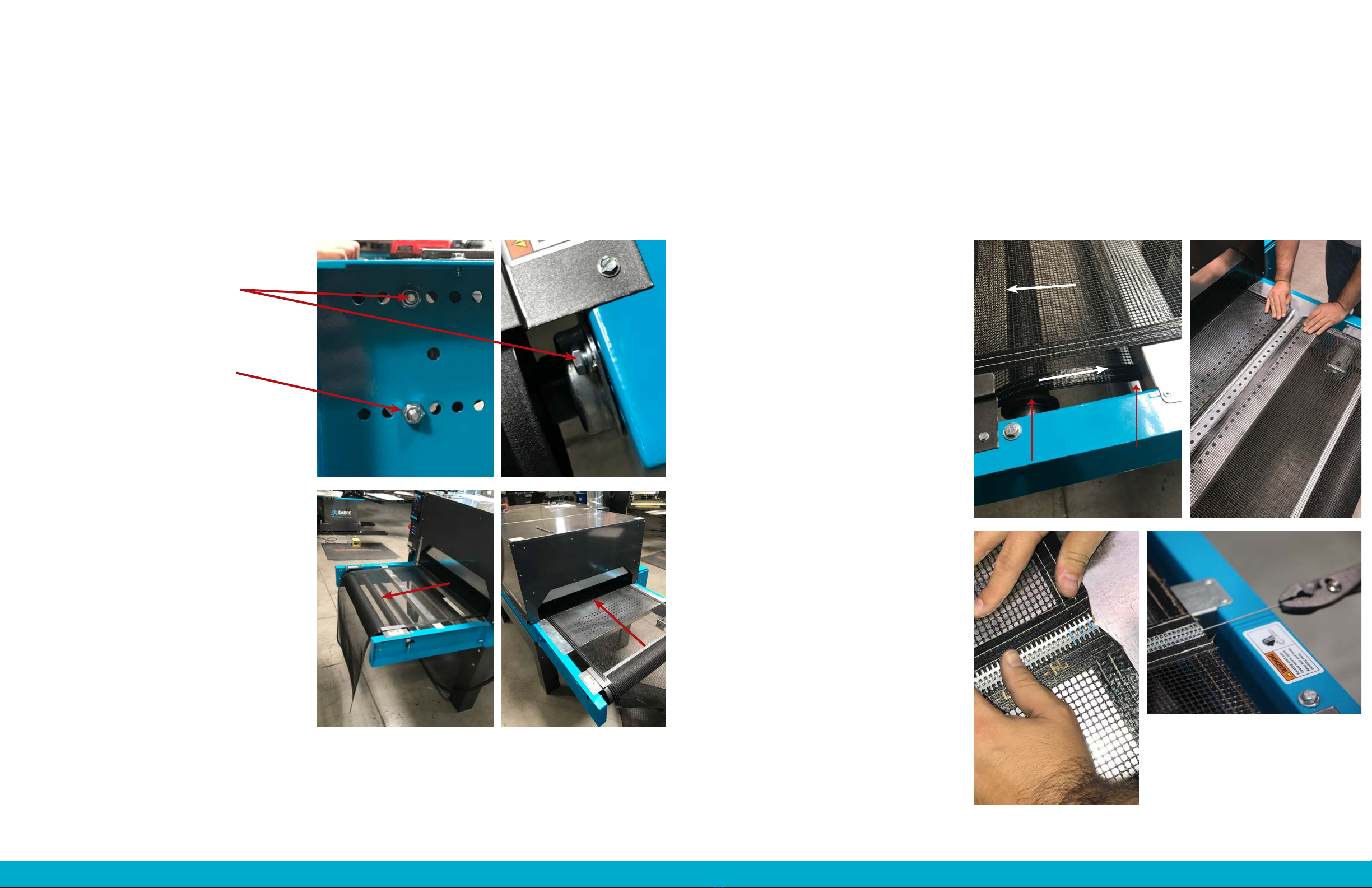

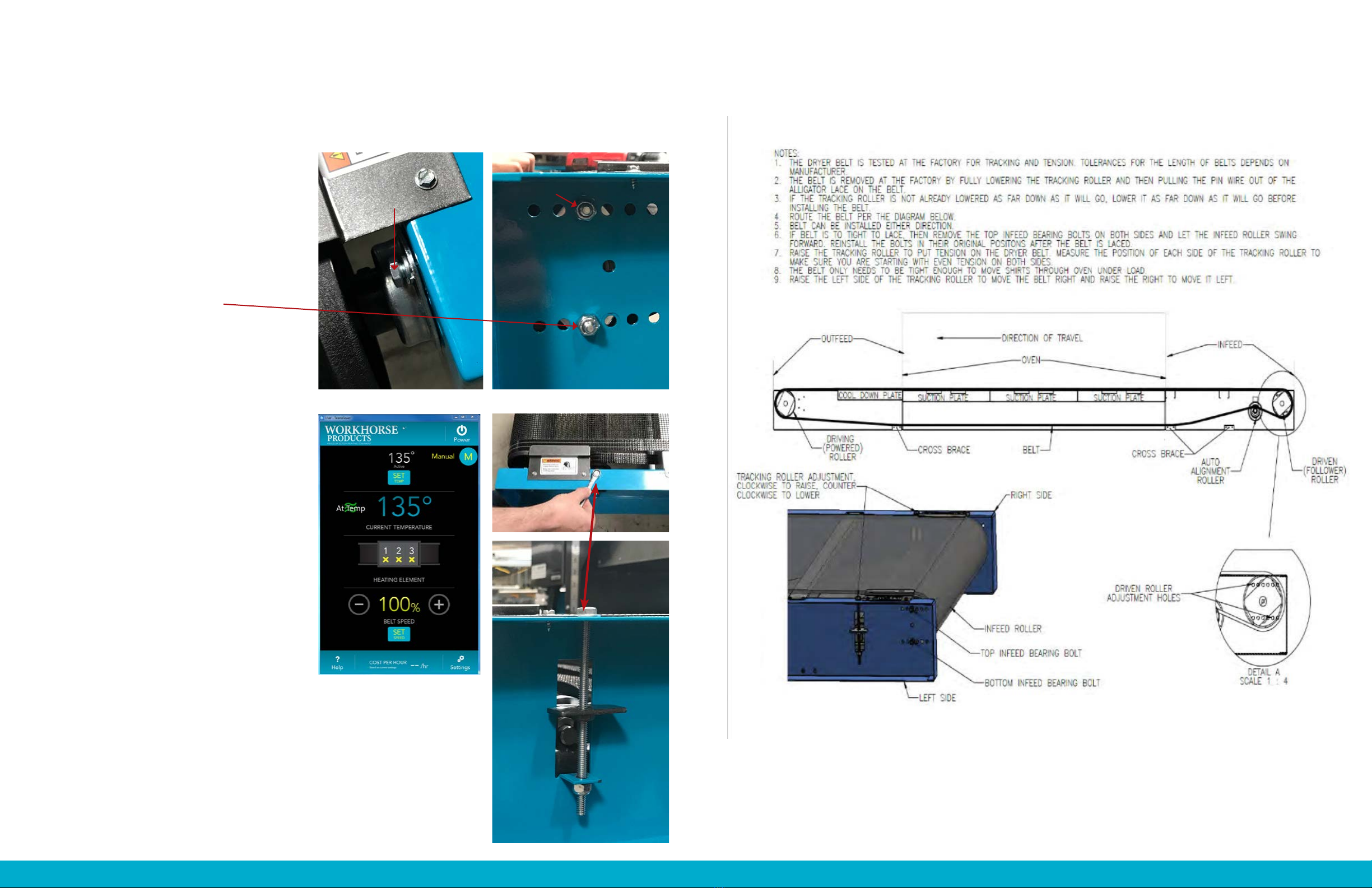

ASSEMBLY

STEP 5: CONNECTING THE BELT DRIVE MOTOR

On the outfeed side, take the

belt drive motor cable and feed it

through the hole located at the edge

of the arm.

Connect the belt drive motor cable

to the motor cable.

Congratulations!

The Powerhouse Series II Dryer is

now fully assembled!

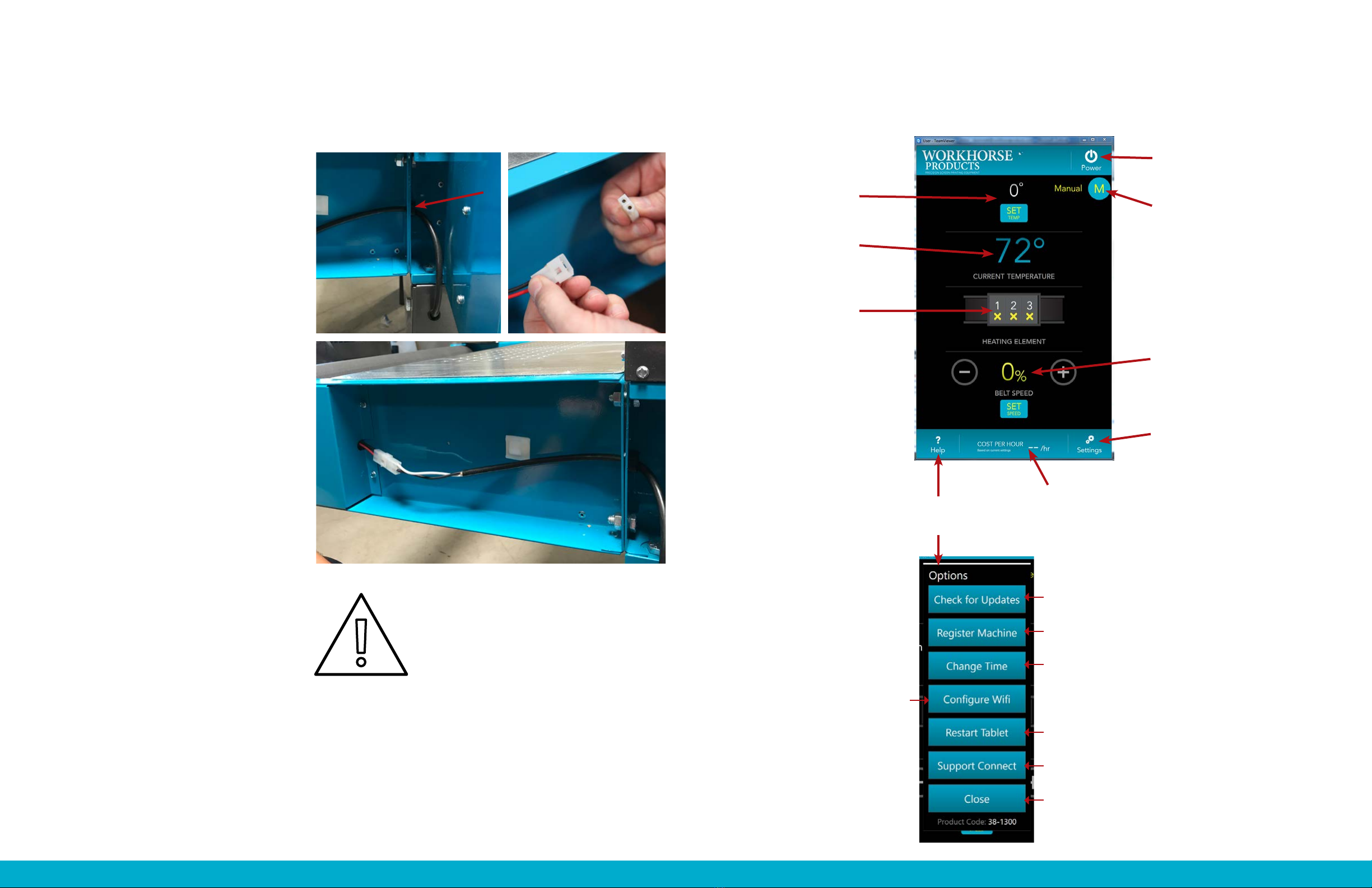

The size and specifications of the electrical connections made during installation MUST BE

DETERMINED BY A LICENSED ELECTRICIAN. FOLLOW ALL LOCAL BUILDING AND PLANNING

CODES. Failure to do so may result in damage to the unit, building, or cause serious injury.

Before any electrical connections are made verify all safety precautions have been taken to ensure

the safety of all shop personnel. The dedicated breaker providing power to the dryer MUST BE

OFF, AND USE OF A SERVICE LOCKOUT TAG IS REQUIRED. This will prevent anyone from turning

on the power as the connections are being made. After all safety precautions have been taken

the electrical connections can be made. All electrical connections must be made by a licensed

electrician. Refer to factory specifications for proper installation.

1.

2.

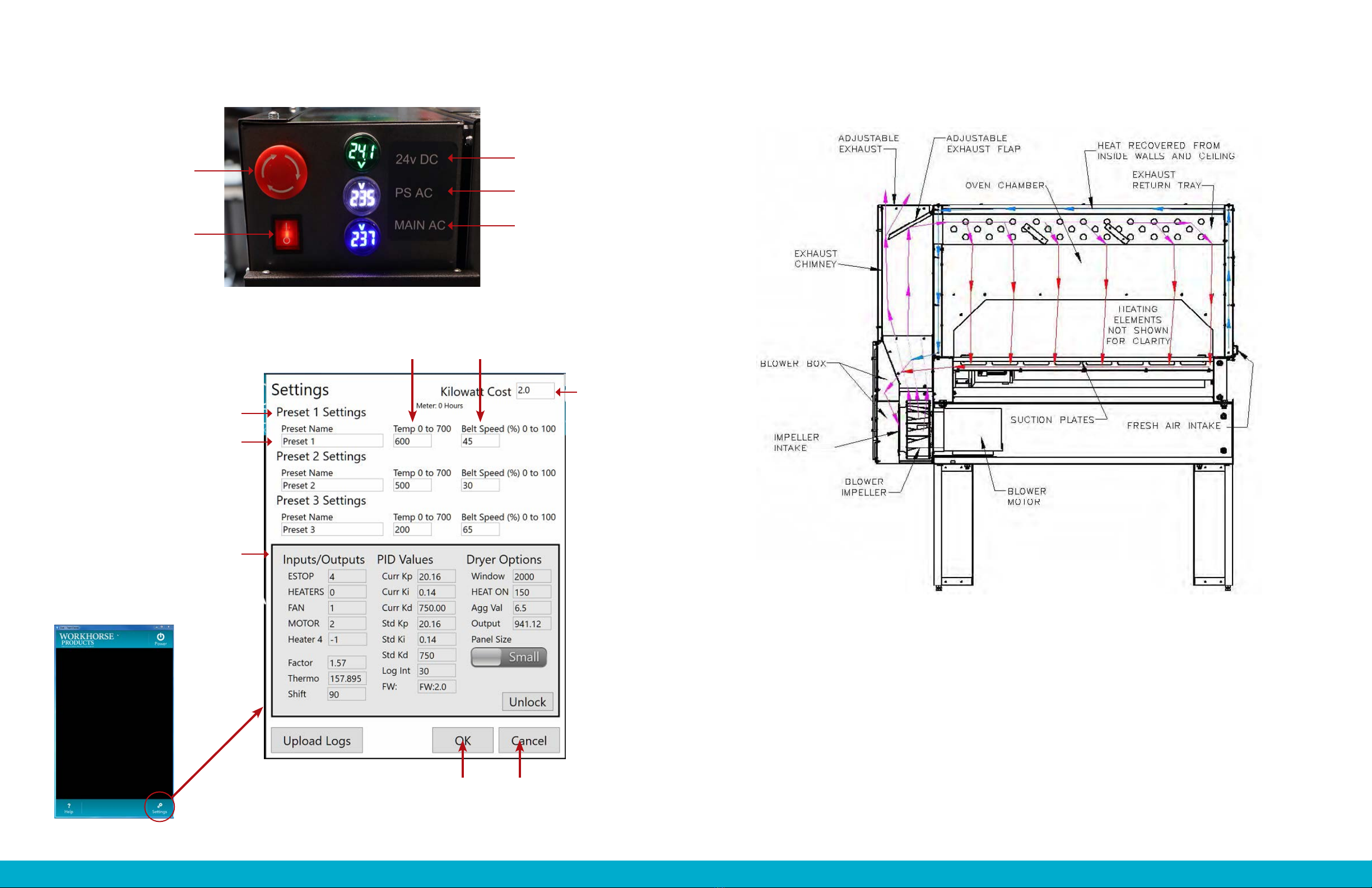

CONTROLS

SET TEMPERATURE

The temperature the

dryer is set to achieve CURRENT MODE

The mode the dryer is on.

For example, if set to a preset,

the preset’s name would be the

current mode. Manual mode

means that the dryer is set to

manual settings without a preset.

BELT SPEED

The speed of the belt

Before turning the dryer on make sure that the belt is empty.

Touch the idle screen so it opens up into the main menu (shown below)

OPERATING COSTS

Based on temperature, airflow, and

exhaust settings the dryer is able to

calculate price per hour for every job.

CURRENT TEMPERATURE

The temperature the dryer

is currently at

HEATING ELEMENTS

Indicates the status of the

heating element. Whether

the heating element is

receiving power or when it

is actually on.

POWER

Turn the dryer on/off

SETTINGS

Opens the Settings

Menu (see pg. 16)

HELP

Opens the

Options Menu

CHECK FOR UPDATES

Checks for system updates (Wi-Fi Connection required).

REGISTER MACHINE

Registering the machine to the portal will allow you to update

the dryer and store machine logs in the service portal

CHANGE TIME

Adjusts the date and time on the machine.

CONFIGURE WI-FI

Opens the Wi-Fi configuration menu

where the machine can connect to Wi-Fi.

When connected to the Wi-Fi the

machine can receive updates,

communicate with the cloud, and allow

for remote troubleshooting.

RESTART TABLET

This will turn the tablet all the way off and reboot back to

the home screen. This may need to be done on occasion.

SUPPORT CONNECT

This will allow a Workhorse Tech to log in to your tablet to

see log files and/or other issues you may be having.

CLOSE

Will close the sub-menu and return to the Main Menu.