Rev 9.0/1-18 1 STT1: #35151

TABLE OF CONTENTS

TABLE OF CONTENTS ...................................................................................................... 1

SPECIFICATIONS............................................................................................................ 2

WARNINGS ..................................................................................................................... 2

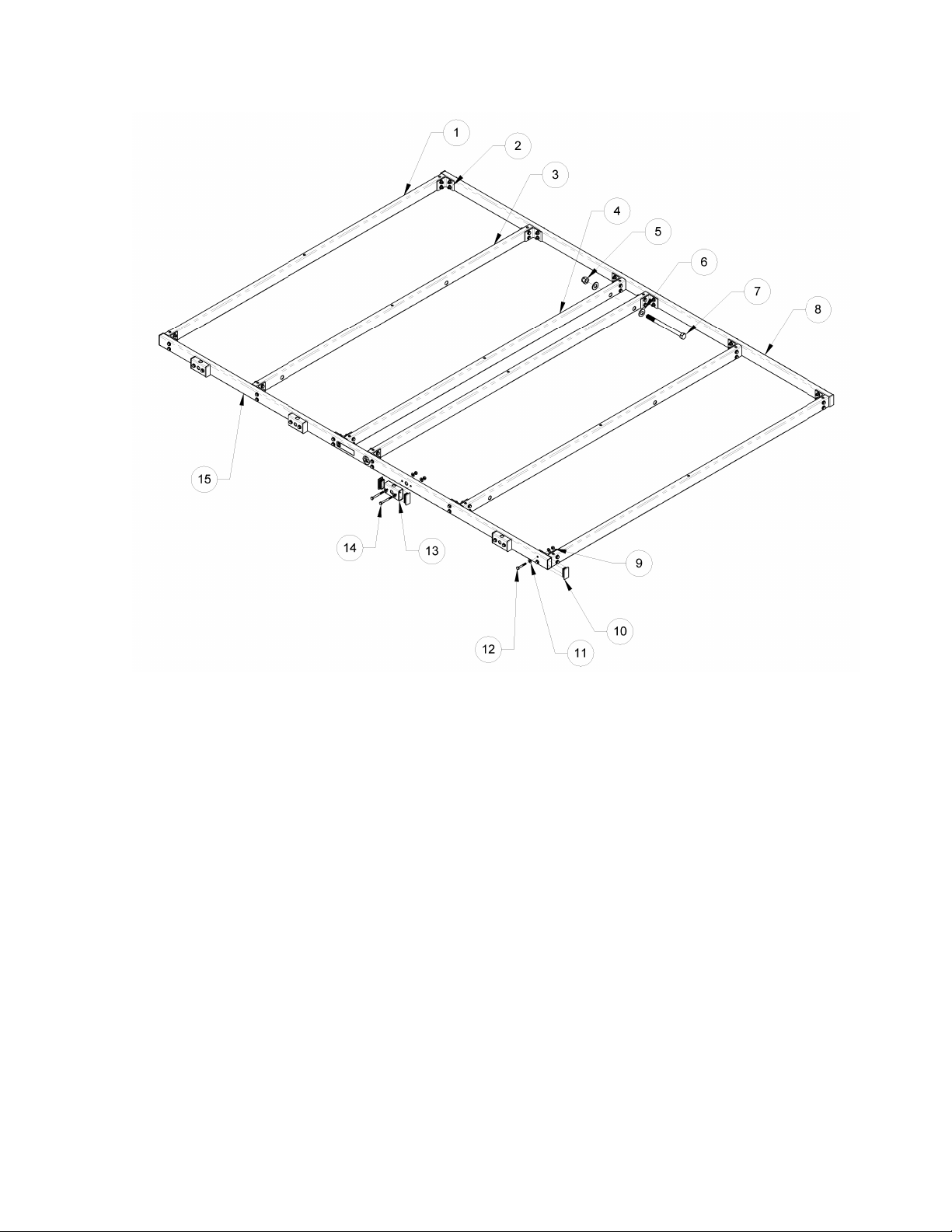

ASSEMBLY....................................................................................................................... 3

USAGE FEATURES ........................................................................................................... 9

USAGE ........................................................................................................................... 10

BEFORE USING THE TABLE ............................................................................................... 10

Taking Safety Precautions ..........................................................................................................................10

Evaluating the Intended Use.......................................................................................................................10

TO FOLD UP OR UNFOLD THE TABLE ................................................................................... 10

TO LOAD THE TABLE........................................................................................................ 11

TO TILT THE LOAD .......................................................................................................... 11

TO TRANSPORT THE LOAD ON THE TABLE ............................................................................ 12

TO UNLOAD THE TABLE.................................................................................................... 12

AFTER USING THE TABLE ................................................................................................. 12

MAINTENANCE.............................................................................................................. 13

INSPECTION SCHEDULE ................................................................................................... 13

Every-Use Inspection .................................................................................................................................13

Frequent Inspection ...................................................................................................................................13

Periodic Inspection ....................................................................................................................................13

Infrequent Use ..........................................................................................................................................13

TESTING SCHEDULE ........................................................................................................ 13

MAINTENANCE SCHEDULE ................................................................................................ 13

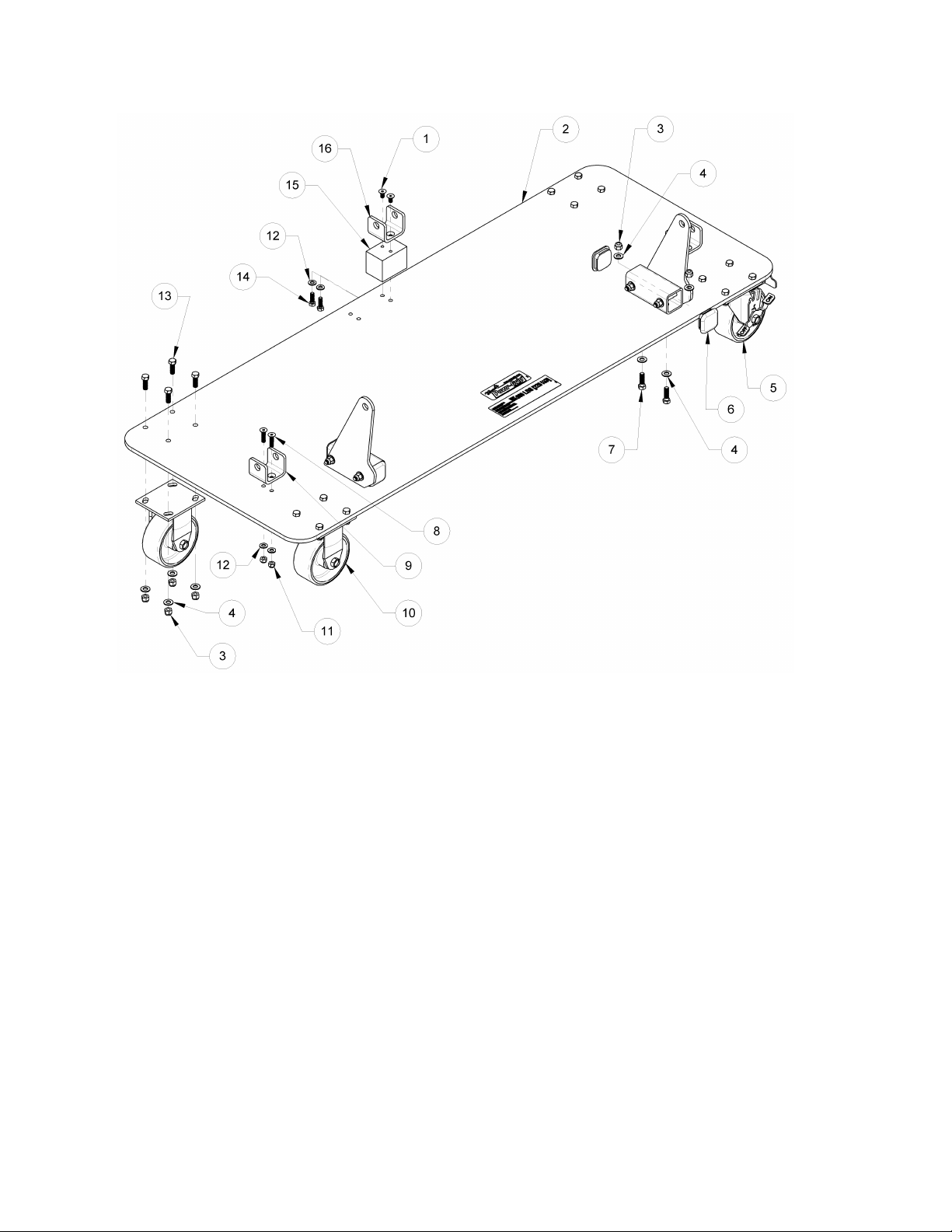

REPLACEMENT PARTS LIST .......................................................................................... 14

LIMITED WARRANTY.................................................................................................... 15