3

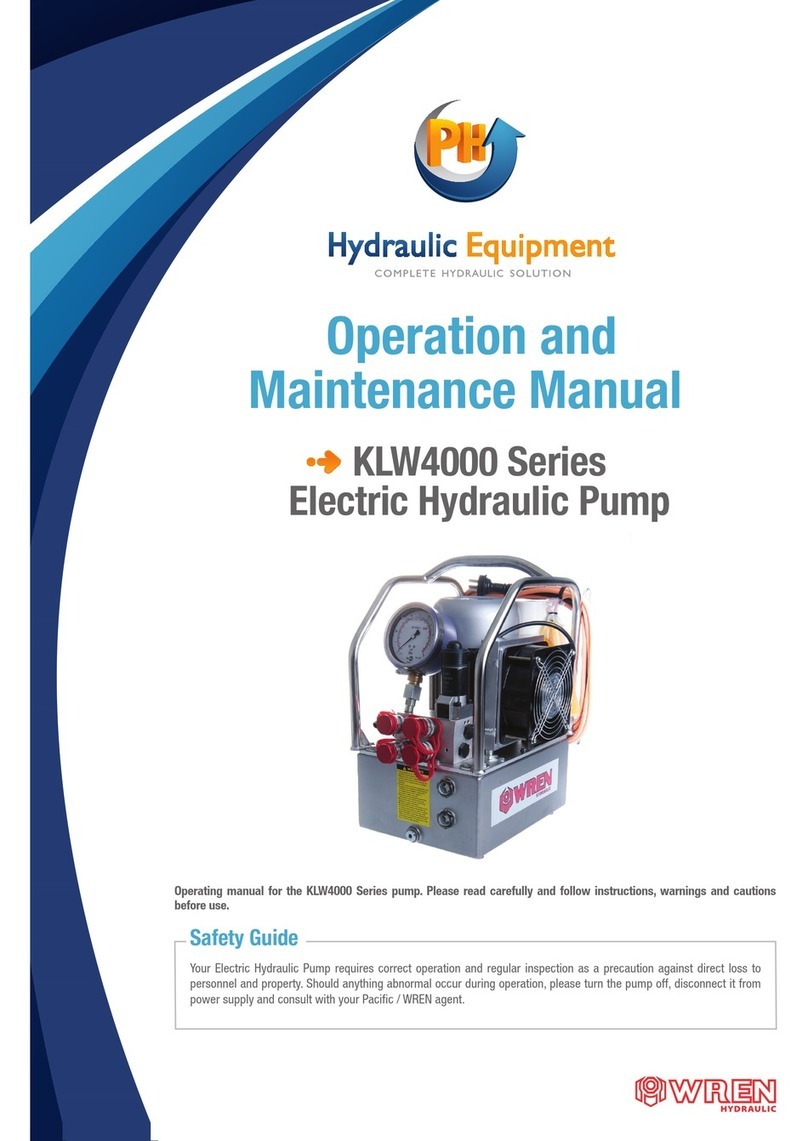

Description

1. The KLW4000N Series air hydraulic pumps utilise an integrated assembly; consisting of an oil pump, control valve, oil reservoir and

air motor to provide an independent and complete hydraulic device. It has the advantages of small volume, light weight, simple robust

structure, convenient operation and high work pressure. The pump utilises high and low oil pressure and can provide a larger oil output than

conventional hand pumps. High pressure and low pressure is controlled by an unloading overflow with automatic no-load return to reduce

power consumption and oil pressure is 70 - 700 Bar (10,000 Psi max).

2. Utilises ISO grade 32 wear-resistant hydraulic oil.

3. Working environment temperature; -10 to +60oC.

4. Always use appropriate high pressure hoses and quick couplers.

5. This pump is designed for use with hydraulic products of equal pressure – please consult with Pacific / WREN or their agent if in doubt about

an application.

6. Please do not use the hydraulic pump near flames.

428

281

16

15 14

448

3

4

2

1

10

12

13

11

6

79

8

5

•

Oil reservoir

•

Bolt

•

Air motor

•

Oil water separator

1

2

3

4

•

Protecting frame

•

Quick coupler

•

Adjustable pressure regulator

•

Oil level gauge

9

10

11

12

•

Oil port

•

Screw

•

Cover plate

•

Oil port

16

15

14

13

•

Air input valve

•

Radiator

•

Air valve

•

Pressure gauge

6

7

8

5

Parts for the KLW4000N Series Pump

Description of Parts

•

Oil reservoir; contains the oil.

•

Bolt; fixings to connect motor and oil reservoir.

•

Air motor; power 4-8 Mpa.

•

Oil water separator; displaces water from oil.

•Air input valve; to control the low pressure air into the system.

•

Radiator; to dissipate heat ensuring longer operating time and

life of the pump.

•

Air valve; to output oil when the pressure is very high and control

the oil flow return. Can be used up to maximum pressure, the

thread type of the port is 1/4 NPT.

•

Pressure gauge; ranges from 0-70 Mpa to 0-10000 Psi .

1

2

3

4

5

6

7

8

•

Protection frame; protects pump assembly and can be used for

carry frame for ease of transportation.

•

Quick coupler; for ease of attachment for both tools and hoses.

•

Adjustable pressure regulator; regulates the high pressure + or – to

the set up pressure to the attached equipment.

•Oil level gauge; indicates the current oil level, when the level is below

1/3rd of the reservoir storage capacity; oil must be added.

•

Oil port; port on base of tank for removal of used oil.

•

Screw; to fix the reservoir to the pump housing.

•

Cover plate; air tight sealing for the oil reservoir.

•

Oil port; includes breather cap which has a pre-filter to prevent

access of dirt into the tank.

9

10

11

12

13

14

15

16