8

FIG2

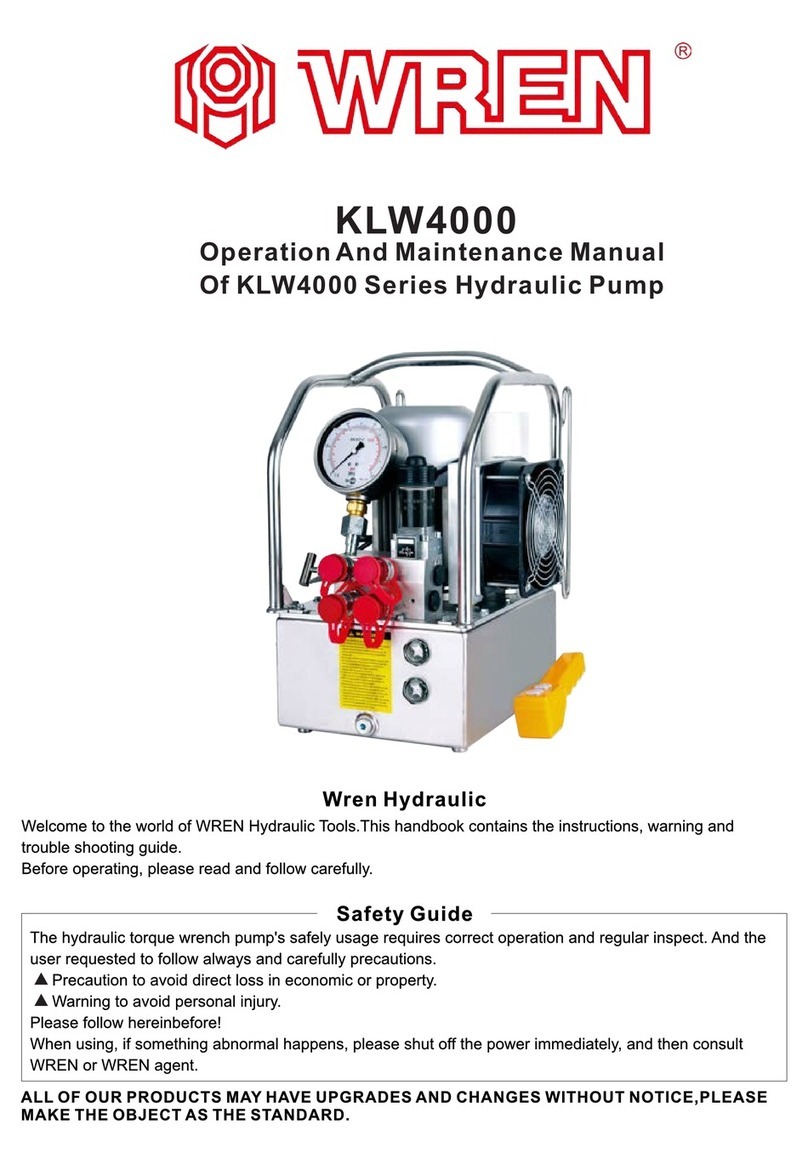

1.KLW4010N hydraulic power pump is designed for hydraulic torque wrench. There is a 2-way,

4-position Air control valve on the pump, port A is high pressure point, it can export the oil at the high

pressure, and port B is low pressure point which can return the oil at the low pressure.

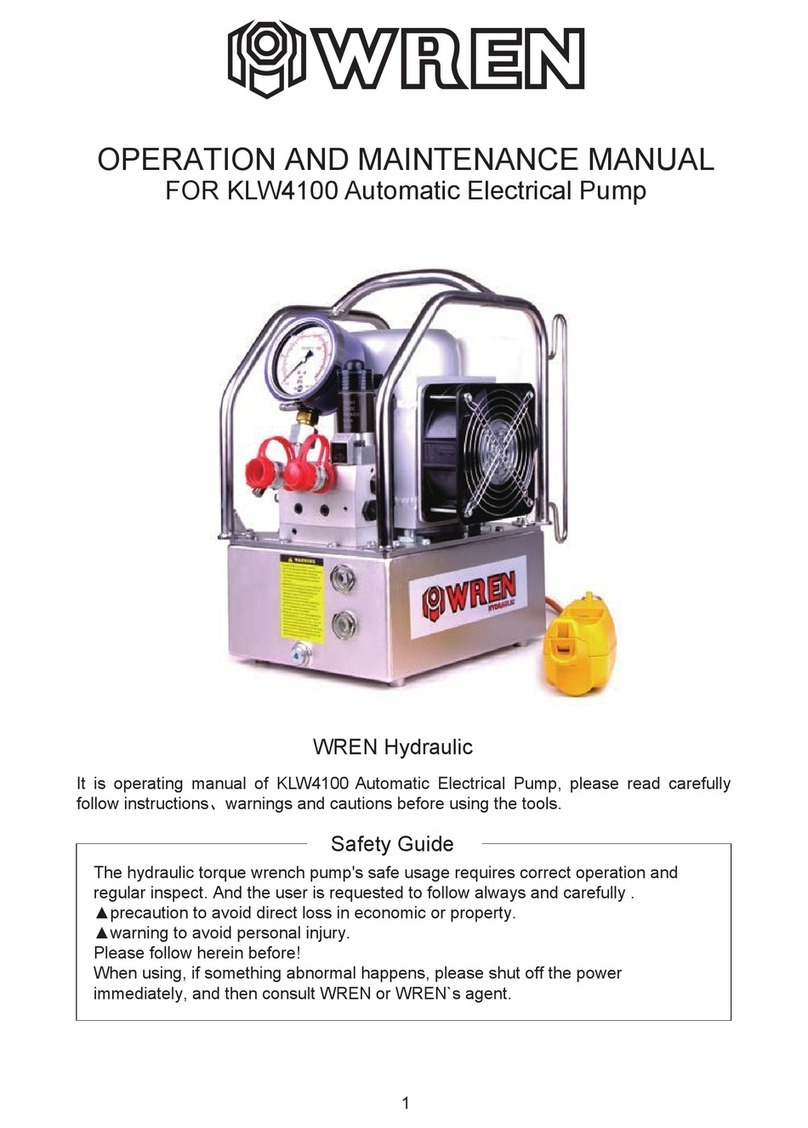

(1)Please loosen the valve for adjusting pressure before operating.

(2)Please connect the air line and press the air input valve on the flank of the pump to make the

pump start working and oil exporting.

(3)Please press the working button on the controller and adjust the pressure unit the working

pressure reach to what you need, and then loosen the working button on the controller.

(4)When the desired pressure is reached, the motor stops working, and the pressure will keep the

same. when the pressure falls down, the motor starts to work again.

(5)When the motor is working, if you press the “off” button on the pump, the motor stops working,

the piston and pressure will also be stopped at the position when the motor stopped working, even

if the pressure fell, the motor would not work again.

(6)After operating, please press the rubber button on the top of the air control valve in order to

release the pressure in hoses and equipments, then you can take down the hose and cover the

Safety cap for the quick couplers.

OPERATION INSTRUCTIONS

TROUBLE SHOOTING GUIDE OF HYDRAULIC PUMP

T Ha ndle

Turn up the preasure

Lock ing Rin g

The pump can't be s tarted

The voltage isn't suitable

Chec k ed the input air, switc h and

distribution box and so on, and

connect the air.

Confirming whether the voltage

is s uitable for the pump's need

The power hasn't be connected

The system has no pres s ure

The quick coupler hasn't be

connected to the correct position Take down and reinstall it

No oil in the oil res ervoir Fill in oil

Not enough oil in the oil reservoir Fill in oil

If the system has a throttle and

hand single-direction valve, please

check if the valve are open

Open the throttle and hand

single-direction valve, and

make sure the system is a circle

After reinstalling the quick

coupler,the system has no

pressure

The quick coupler can't be connected

to the correct position, which causes

no pressure in the system

Take down the quick coupler, check

if the boll is elastic with a rod, if it can't

move, please knock it with a hammer to

eliminate the mist hydraulic oil

Leakage in the quick coupler The o ring and escape have worn out Replace the quick c oupler