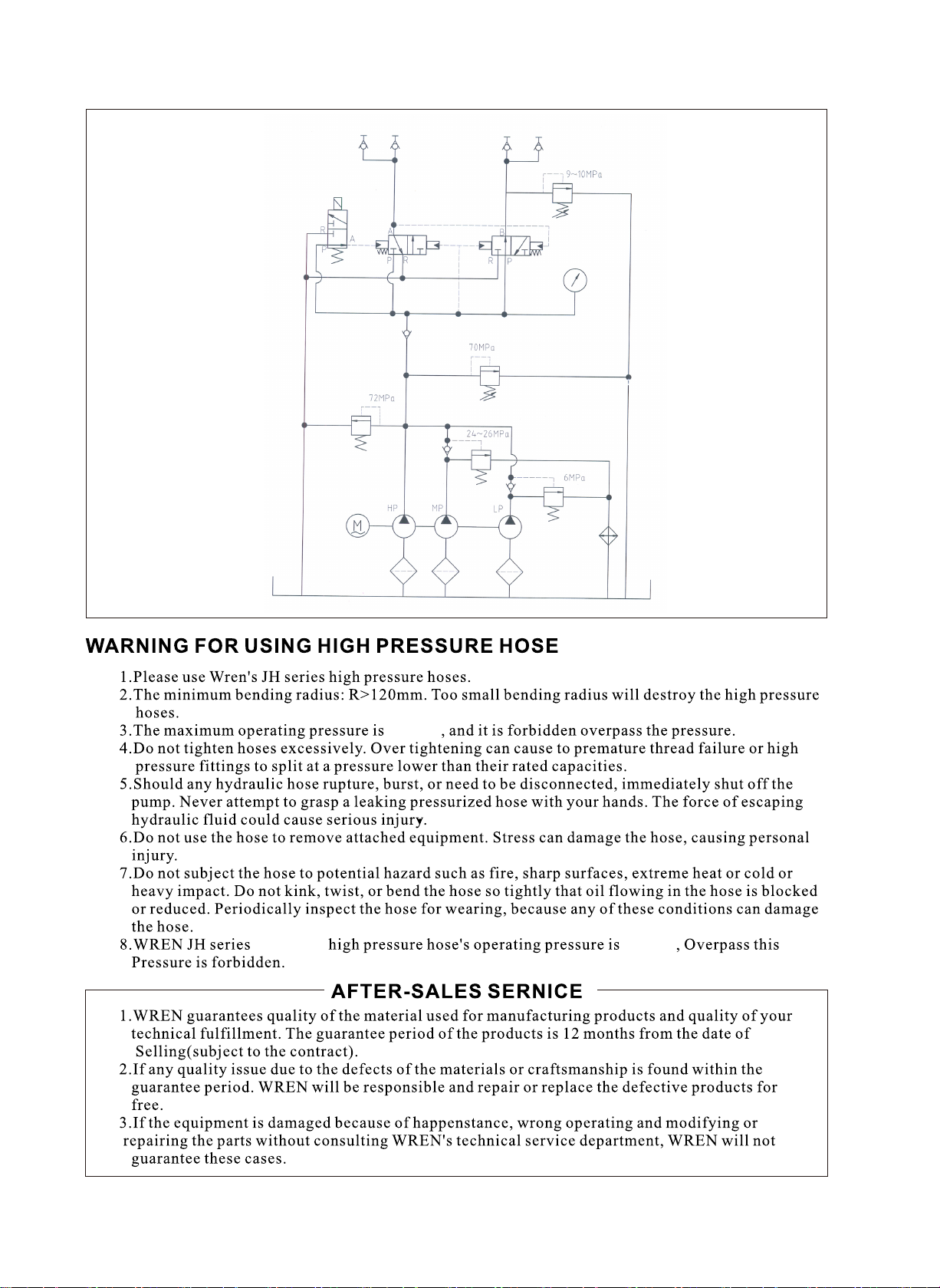

Mal function Reason for caused malfunction Solution

The pump can not be started Un-suitable power source Confirm if the power meets pump’s

need

The power is not connected Check the power

The system has no pressure

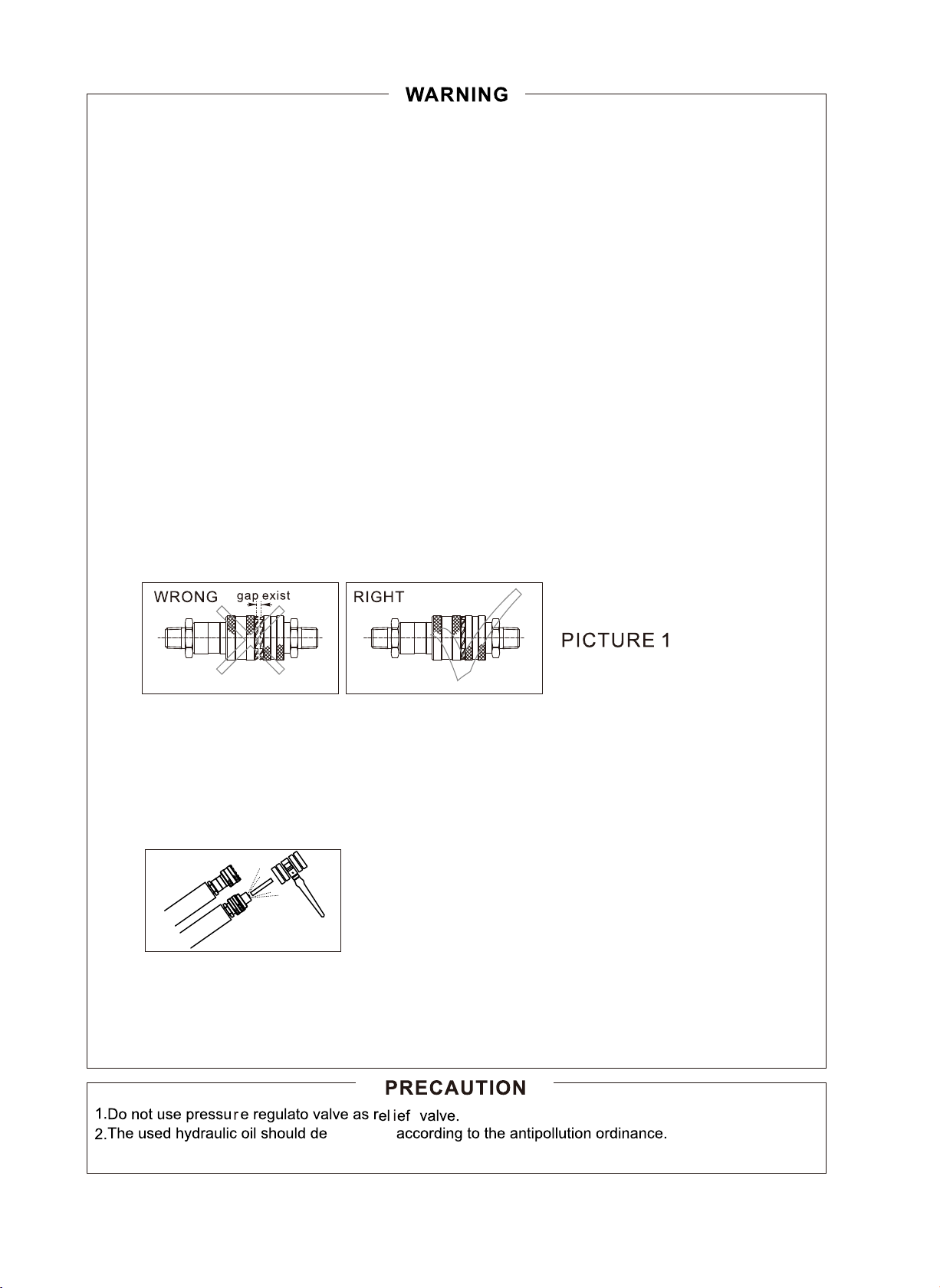

The coupler is not connected

properly Re-install

No oil in the tank Fill oil

Not enough oil Fill oil

Check if flow control valve, single-

direction valve in the system is open

Open the flow control valve to ensure

the system is connected

The system has no pressure

after reinstall the couplers

The couplers is not connected in

the properly position

Uninstall the couplers, check if the steel

roll is elastic with a rod, if it can not move

please knock it with hammer to elimina

te the mist hydraulic oil.

Leaking in the couplers The o-ring, retaining ring worn

out in the couplers Replace the couplers

The pressure for high-pressure

leaking valve is adjusted too low Please check the gauge, adjust it to

rated value

Oil is mixed with water Replace the oil, please

Ball steel in pressure relief valve

may be broken or the valve seat

may be frayed

Replace them,please

Air may be sucked into the system Repeat operating the system with no

load for several times to eliminate air

The leaking valve may be frayed Replace it, please

High-pressure leaking valve may

not be tightened Tighten it, please

The o-ring for high-pressure leaking

valve may be broken Replace it, please

There may be some inclusion into

the oil

Wash the power pack valve and

replace oil

The system pressure can

not reach to the rated

pressure

There is a strong noise

when the power pack is

operated

The bearing may be broken

Air may be mixed into this power

pack

Replace it, please

Exhaust the air from the system

When using under static

pressure, the pressure

reduces slowly

The seal is out of control,please

check all the seal Replace the seal

Piston or spring may be broken Change them, please

Leaking may be happened at

brushfire position Tighten the couplers and replace

the seals

Oil lever may be too low

High-pressure system may not

eliminate the oil fully

Please try several times without load

before using

Too low oil temperature may make

lead to suck oil difficultly

Control the temperature at -10℃ to

60℃ ,please

Oil temperature may be too high

that cause the damage of pump

If so, the power pack need to be

replaced with new one

High-pressure flux is not

enough

Fill the oil,please

TROUBLE SHOOTING GUIDE OF HYDRAULIC PUMP

8