3

www.XSscuba.com

XS Scuba Inspire Regulator Service Manual

Maintenance Schedules

Regulators are subjected to a variety of environmental

elements that over time can affect their performance. Salt,

sand, sediment, chlorine and other chemicals all take

their toll on a regulator. Soft parts wear out and lubricants

break down and wash away. As an XS Scuba Dealer, you

are advised to inform your staff and customers that

XS Scuba regulators require servicing at least once a year.

Under certain circumstances service is required every 3-6

months. Some of those circumstances are:

1. Frequent or improper use

2. Inadequate routine freshwater rinsing

3. Regulator use in dirty or polluted waters

4. Rental use

5. Regular use in chlorinated (pool) water

Recommended maintenance schedules are based on

average use under normal conditions and assume that

recommended preventative maintenance and storage

procedures have been followed as outlined in the

XS Scuba Regulator Owner’s Manual.

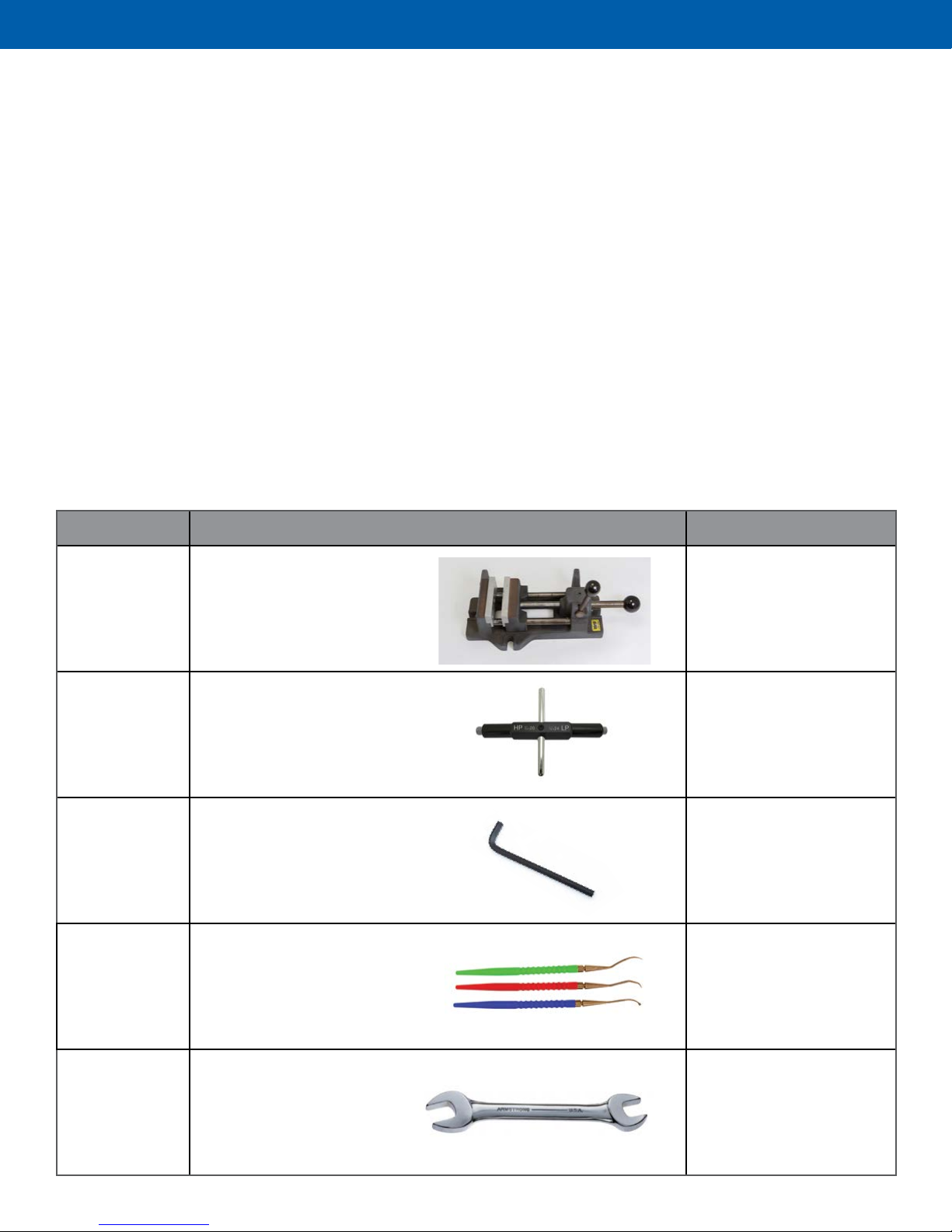

Standard Procedures

1. Preview the list of tools and parts required to perform

the prescribed service outlined in this manual. Follow

each step in the sequence provided. Have this manual

open next to you for reference. Do not rely upon

memory.

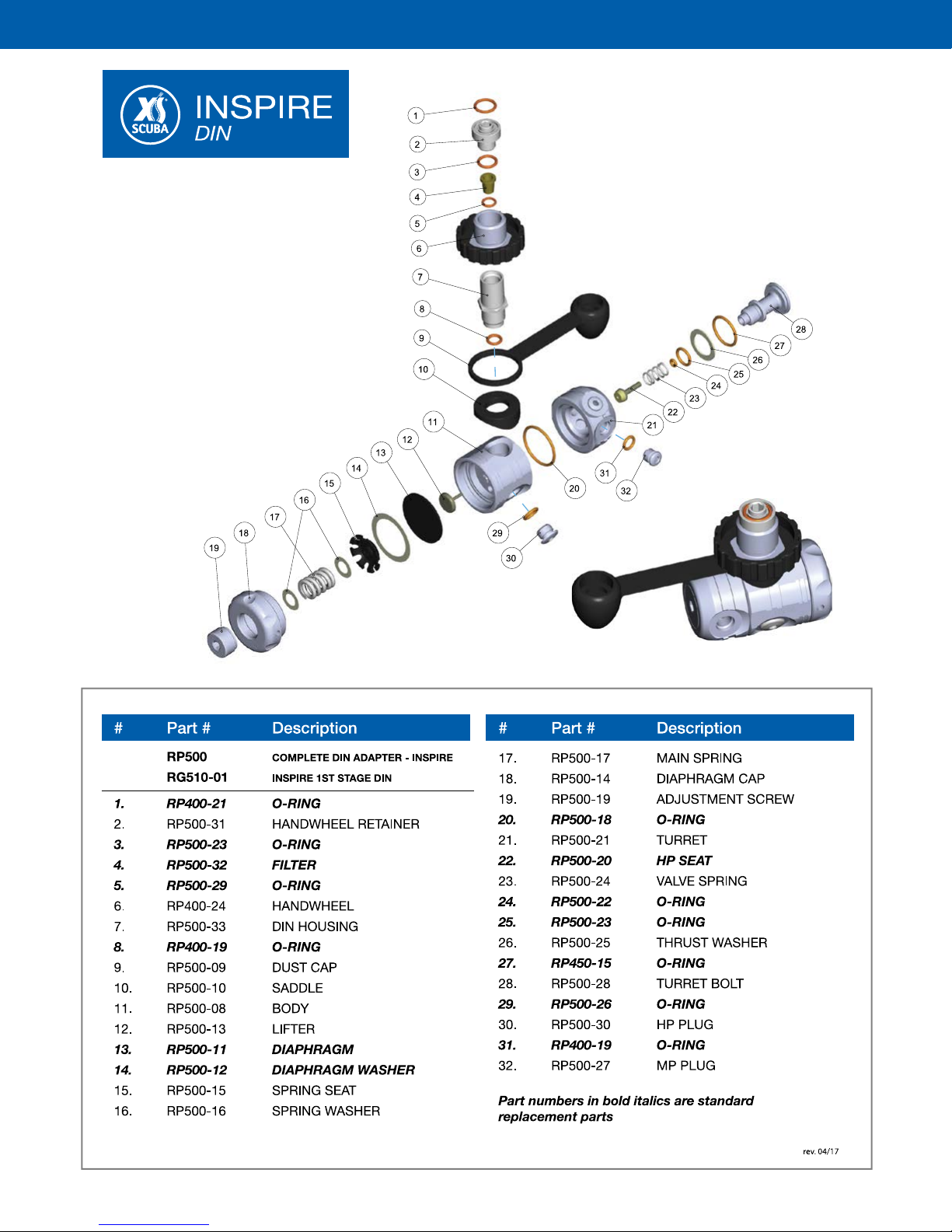

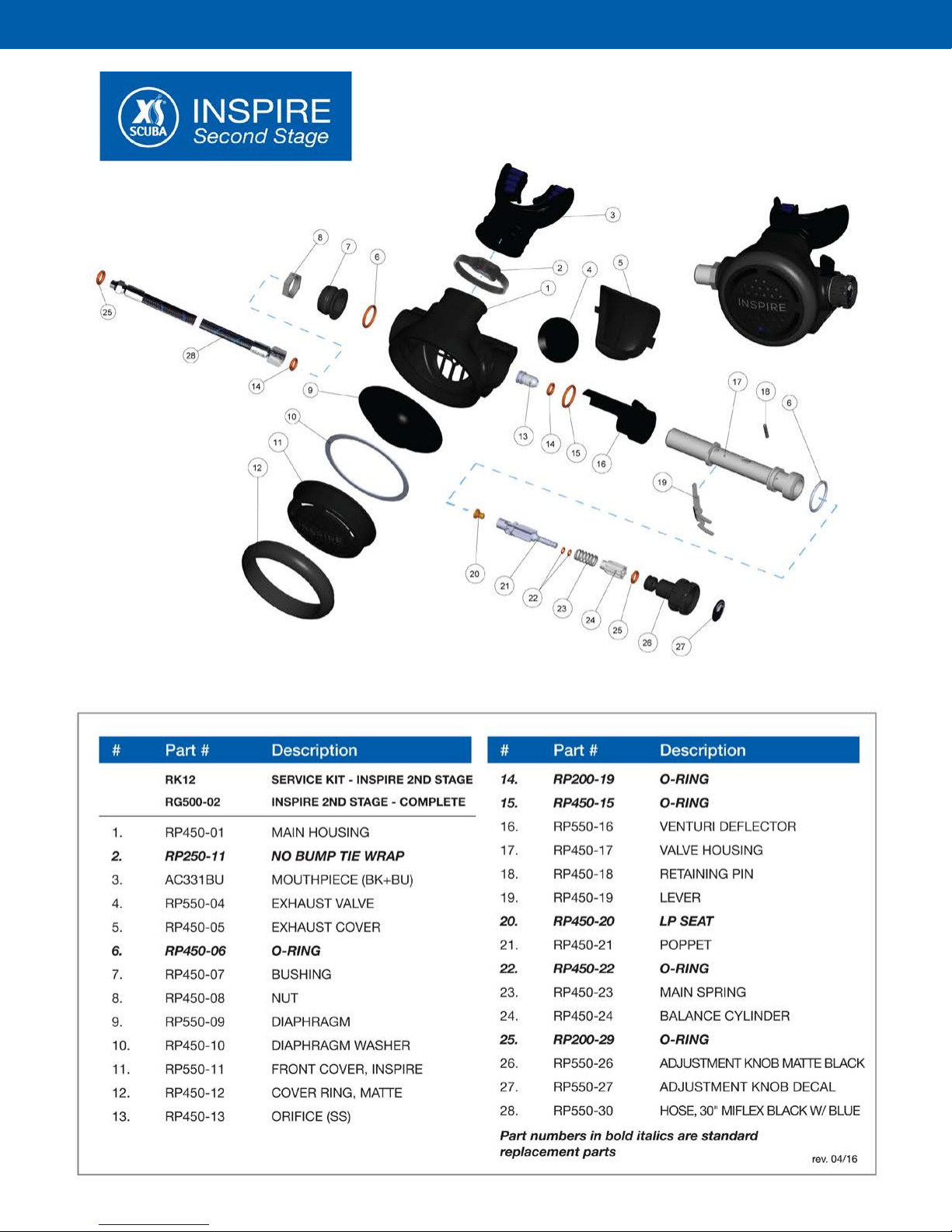

2. Numbers found in parenthesis reference the KEY

numbers in the exploded diagrams. If you are not sure

what a part is by its description, use this number to

cross reference it in the exploded diagram.

3. All regulator services should be performed on a

workbench specically set up and equipped for this

purpose. Adequate lighting and cleanliness along

with easy access to the required tools should be

considered mandatory.

4. Delicate parts, such as parts with critically machined

surfaces should be isolated from the other parts

to prevent damage, especially during the cleaning

procedure.

5. Only use factory authorized parts provided by

XS Scuba. Do not attempt to substitute other

manufacturer’s parts regardless of any similarity in

appearance. This is especially true for o-rings!

6. Do not attempt to reuse mandatory replacement

parts regardless of how much use those parts were

subjected to.

7. When reassembling, it is important to follow factory

mandated torque values using a calibrated torque

wrench. To do otherwise could lead to damage or

failure of the product.

8. Unless otherwise instructed, the following is

assumed:

a. When instructed to remove, unscrew or

loosen a threaded part, turn the part

counterclockwise. The manual abbreviates

counterclockwise with CCW.

b. When instructed to install, screw in or tighten

a threaded part, turn the part clockwise.

The manual abbreviates clockwise with CW.

9. The following abbreviations are used throughout this

manual:

a. HP = High Pressure – the pressure entering a

regulator from the cylinder e.g. 3000psi

b. MP = Medium Pressure – the pressure leaving

the rst stage traveling to the 2nd stage. Also

referred to as intermediate or interstage pressure

c. LP = Low Pressure – the pressure exiting the

2nd stage through the mouthpiece. Also referred

to as ambient pressure.

Nitrox Compatibility

XS Scuba regulator products may be safely used with

enriched air nitrox (EAN) that does not have an oxygen

content greater than 40% (EAN40), if the regulator is

properly cleaned and prepared. Properly cleaned means

that a mild detergent is used to remove hydrocarbons

such as compressor oils. Properly prepared means that

only authorized parts and lubricants are used during

reassembly. Gloves should also be worn to prevent skin

oils from contaminating the parts. See the section on

“Cleaning and Lubricating”

Regarding nitrox safety and compatibility, the concerns

lie primarily with the rst stage as it is subjected to

high supply pressures. High supply pressures lead to

adiabatic compression or heating of the gas. XS Scuba

regulator rst stages are authorized for use up to EAN40

because they contain oxygen compatible parts and

lubricants and are built in a clean environment.

For the rst stage to remain EAN40 compatible, only use

hyper ltered compressed gas (hydrocarbons < 0.1 mg/

m3). Ordinary compressed breathing air (Grade E) usually

does not meet this criterion. Once ordinary breathing air

is used, the rst stage is no longer EAN40 compatible

until it is cleaned and serviced again.

Although regulator second stage components are not

exposed to high pressure EAN, XS Scuba recommends

that the same cleaning procedures be followed for the

complete regulator. This prevents the possibility of cross

contamination and guarantees the cleanliness of the

entire regulator.