3

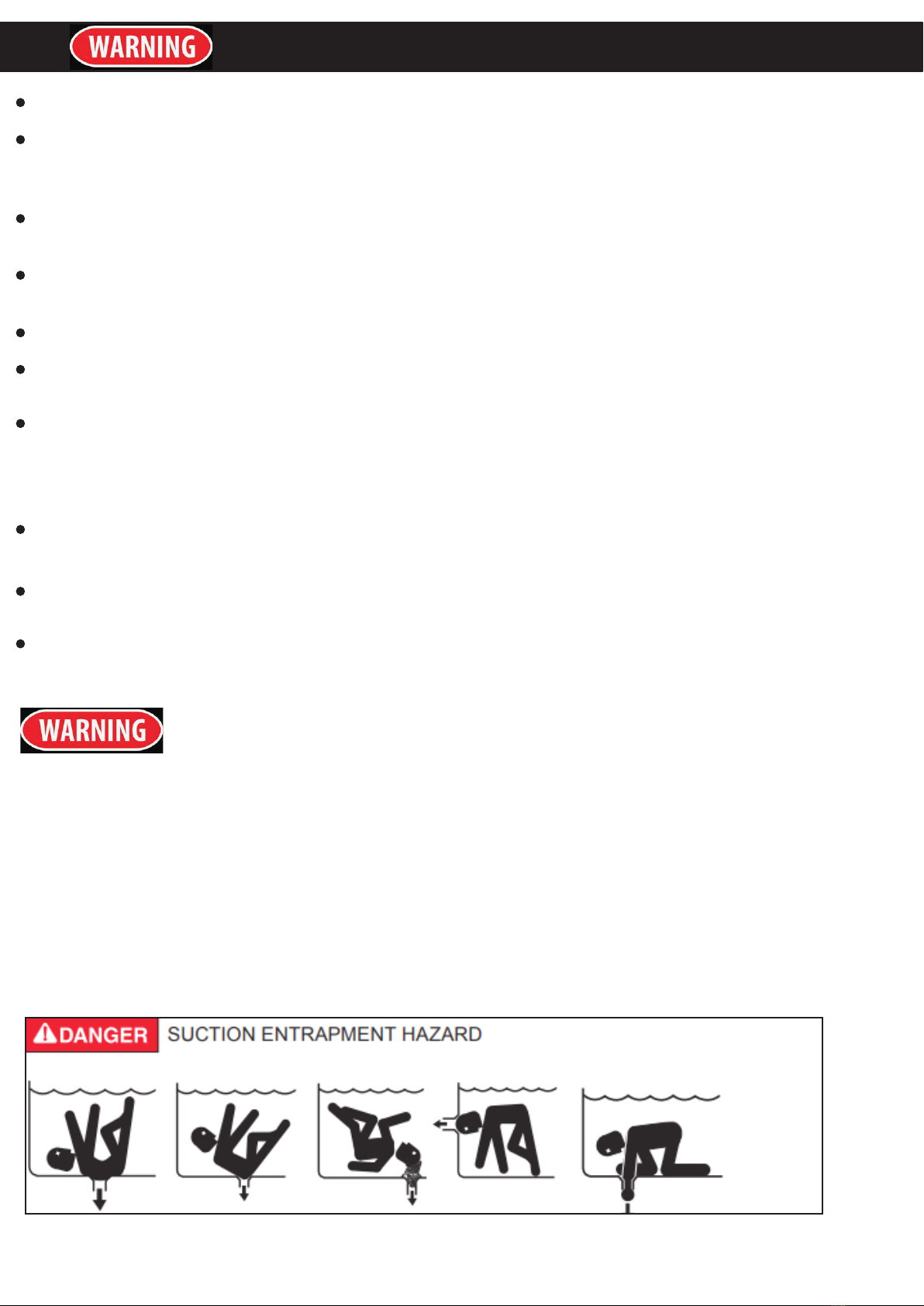

POOL AND SPA PUMPS MOVE LARGE VOLUMES OF WATER, WHICH CAN POSE EXTREME

DANGER IF A PERSON;S HAIR COMES IN PROXIMITY TO A DRAIN THAT IS NOT THE PROPER

SIZE FOR THE PUMP OR PUMPS.

The Virginia Graeme Baker Pool and Spa Safety Act imposes certain new requirements on owners and

operators of swimming pools and spas. Pools or spas constructed on or after December 20, 2008, shall

utilize:

(A) No submerged suction outlets, a gravity drainage system with ASME/ANSI cover(s), one or more

unblock-able outlets; or

(B) A multiple main drain system without isolation capability with suction outlet covers that meet ASME/

ANSI A112.19.8 Suction Fittings for Use in Swimming Pools, Wading Pools, Spas, and Hot Tubs and

either:

(I) A safety vacuum release system (SVRS) meeting ASME/ANSI A112.19.17 Manufactured Safety Vacuum

Release Systems (SVRS) for Residential and Commercial Swimming Pool, Spa, Hot Tub, and Wading Pool

Suction Systems and/or ASTM F2387 Standard Specication for Manufactured Safety Vacuum Release

Systems (SVRS) for Swimming Pools, Spas and Hot Tubs or

(ii) A properly designed and tested suction-limiting vent system or

(iii) An automatic pump shut-off system. Pools and spas constructed prior to December 20, 2008, with a

single submerged suction outlet shall use a suction outlet cover that meets ASME/ANSI A112.19.8 and

either:

(A) A multiple main drain system without isolation capability, or

(B) A safety vacuum release system (SVRS) meeting ASME/ANSI A112.19.17 and/or ASTM F2387, or

(C) A properly designed and tested suction-limiting vent system, or

(D) An automatic pump shut-off system, or

(E) Disabled submerged outlets, or

(F) Suction outlets shall be recongured into return inlets.

This lter operates under high pressure. When any part of the circulating system (e.g., clamp, pump, lter,

valves, etc.) is serviced, air can enter the system and become pressurized. Pressurized air can cause the

lid or control valve to separate which may result in serious injury, death, or property damage. To avoid this

potential hazard, follow these instructions.

1. Before repositioning valves and before beginning the assembly,

disassembly, or adjustment of the clamp or any other service of the circulating system:

(a) Turn the pump off and shut off any automatic controls to ensure the system is not inadvertently started

during the servicing;

(b) Open manual air relief valve;

(c) Wait until all pressure is relieved, pressure gauge must read zero (0).

2. Whenever installing the lter clamp, follow the lter valve and clamp installation instructions exactly.

3. Once service on the circulating system is complete, follow system restart instructions exactly.

4. Maintain circulation system properly. Replace worn or damaged parts immediately (e.g., clamp, pressure

gauge, relief valve, o-rings, etc.).

5. Be sure that the lter is properly mounted and positioned according to instructions provided.

Failure to operate your lter system or inadequate ltration can cause poor water clarity obstructing

visibility in your pool and can allow diving into or on top of obscured objects, which can cause serious

personal injury or drowning.

This lter operates under pressure. With the valve clamped properly and operated without air in the

system, this lter will operate in a safe manner. Air entering the lter and the valve not clamped

correctly can cause the valve to separate, which could cause serious personal injury and/or property

damage.

IMPORTANT SAFETY INFORMATION