Folkpool Victory User manual

POOL PROGRAM

Victory

ASSEMBLING INSTRUCTIONS FOR ENCLOSURES

revision: 15.3. 2020

99.MP.0056.EN

99.MP.0056.EN - ASSEMBLING PROCEDURE

·Priortoinstallation be suretocheckyourlocalbuildingandzoning requirements.

·Pleasecarryoutthestepsintheorderset out in these instructions.

IMPORTANT

·Pleasereadtheseinstructionscarefullybefore you starttoassembleyourenclosure.

SAFETY ADVICE

·Keeptheseinstructionsinasafeplace for futurereference.

·Wood/composite decking

dizzyspells.

·3.5"thickfoundationofreinforcedconcrete

TOOLS AND EQUIPMENT REQUIRED

·more informations about recommended tools are in this assembling

procedure

·Ifusingastepladderorpowertools,ensure that you followthemanufacturer'ssafetyadvice.

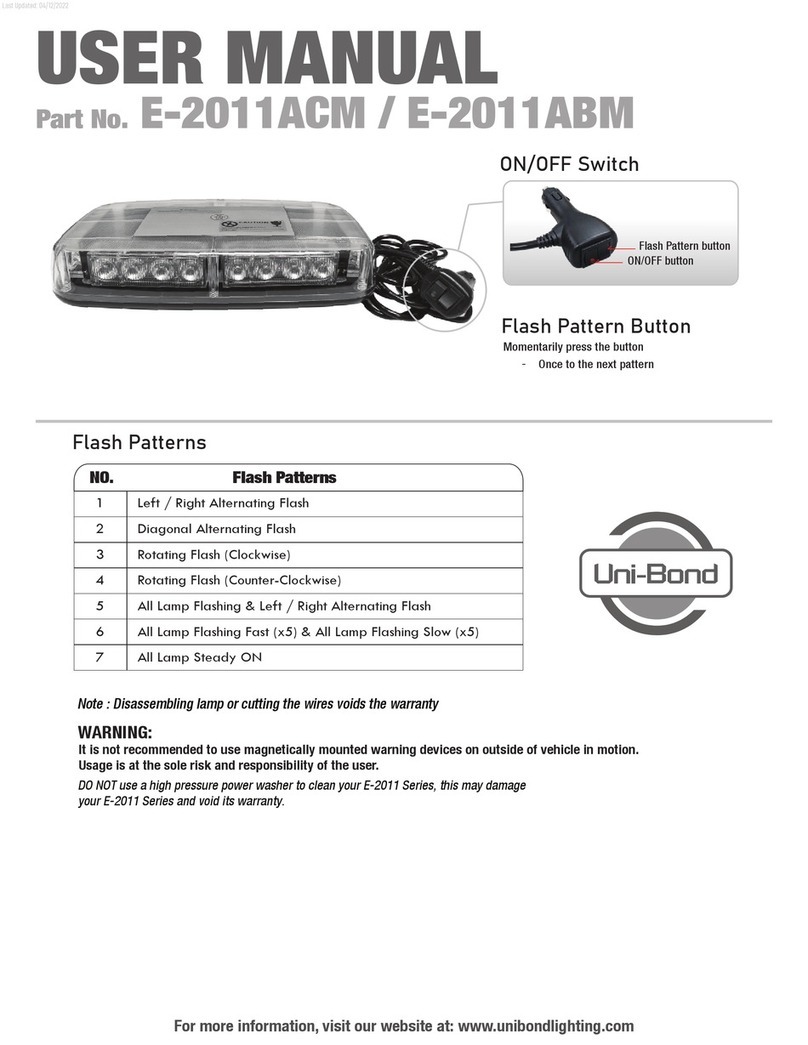

TRACK INSTALATION

Aflat, levelsurfaceisrequired; any of the following is acceptable:

·Use of work gloves and safety glasses during assembly is required.

·Do not attempt to assemble the enclosure in windy or wet conditions.

·Do not touch overhead power cables (if any) with the aluminum profiles.

·Always wear shoes and safety goggles when working with extruded aluminum.

·Dispose of all plastic bags safely - keep them out of reach of small children.

·The enclosure must be positioned and attached on a flat level surface.

·Do not lean against or push t he enclosure during assembly.

·Keep children away from the assembly area.

·Do not position your enclosure in an area exposed to excessive wind or overhead tree limbs.

·Do not attempt to assemble the enclosure, if you are tired, have taken drugs or alcohol or if you are prone to

·Paversset in Concrete

CLEANING

Polycarbonate panels can easily be cleaned by hosing down with cold clean water or with a soft cloth made

from100% cotton using a mild dish detergent solution and rinsing with cold water.

DO NOT use acetone, abrasive cleaners or other special detergents to clean the panels. This will void

warranty!

IMMEDIATE REMOVAL OF PROTECTION SHEETSFROM PANELS

The polyethylene masking (plastic sheets/foil) must be removed immediately from the panels during or

immediately after installation. The polyethylene masking covers the panels to protect them during

handling,hipping, storage, and installation. If it is removed at a later time, it may be very difficult if not

impossible to remove as it will stick to the panel. In hot climates, even 24 hours after the installation is

completed it may be too late to remove.

2 / 63

INTRODUCTION

ITEM

ASSEMBLING INSTRUCTIONS FOR ENCLOSURES

99.MP.0056.EN - ASSEMBLING PROCEDURE

4/63

EXPEDITION - TRANSPORT OF ENCLOSURE TO CUSTOMER

The enclosure for customer is delivery in wooden transport box.

This wooden transport box must be secured on a truck to avoid movement, deformation and damage of the enclosure during

the transport to a client and safer for loading and unloading of the enclosure too.

EXPEDITION - THE ENCLOSURE IS ON A BOARD OF THE TRUCK IN THE WOODEN TRANSPORT BOX

01

02

03

04

05

Segments ( package )

Wooden transport box

Rails ( package )

Faces

Package ( contents for completion of assembly )

TRANSPORT OF THE ENCLOSURE

2

1

3

5

4

01 05 09

02 06 10

03 07 11

04 08 12

Segment nr.1 ( smallest )

Segment nr.2

Lateral door ( on large segment )*

* by this moment. Bottom rail is fixed to travel profile, only the upper rail is removed from the roof.Lateral door is delivered in complet piece

Handle of lateral door

Small detachabled face Plastic cap for rails

Segment nr.3 Large detachabled face

Lock arrestment of segment + stopper

Segment nr.4 ( largest ) Rails End of rail + plastic backstop for travel

ENCLOSURE - MAIN PARTS

1

4

7

10

2

5

8

11

12

3

6

9

99.MP.0056.EN - ASSEMBLING PROCEDURE

5/63

01 02 03 04

The largest face without door The smallest face without door Arrestment of face

Rubber sealing

FACE WITHOUT DOOR - MAIN PARTS

GENERAL PUTTING OF FACE TO SEGMENT

1

2

4

3

99.MP.0056.EN - ASSEMBLING PROCEDURE

6/63

1 6 10 14

2711 15

17

18

16

A

3 8

12

4

5

913

01 08

14

02 09

15

03 10

16

04

05

07

11

12

1306

17

18

A

Arrestment pin

Insert for pavement

Raw-plugs

Plastic cap for end of rail

Plastic backstop for travel

Connection for rail

Screw for fixed attach of face to segment

Screw for fixed of upper rail ( lateral door )

Stopper ( arrestment of segment )

Key for lock of arrestment

Screw for fix of rubber sealing on lath F

Plastic cap for hide of the power cable

Rivets

Plastic cap for gound rails

Sealing rubber for both faces

End of rail

Limit door stop for rail of the lateral door

Self-adhesive mounting tape

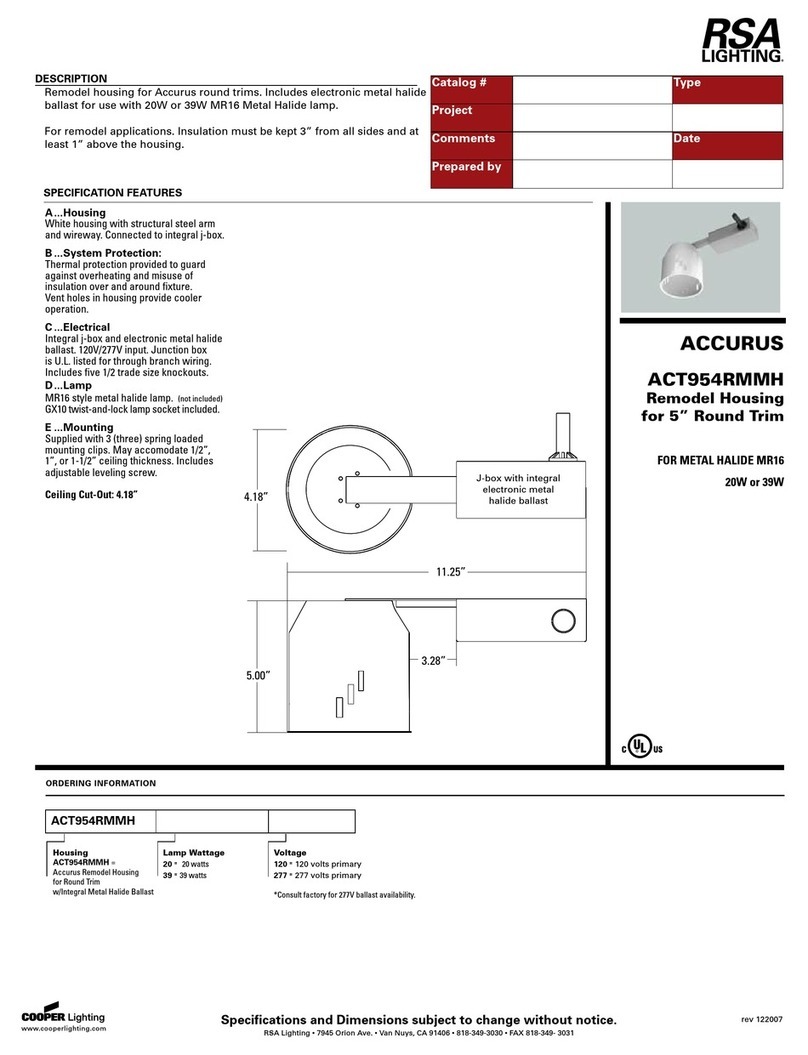

Technical drawing of enclosure

PACKAGE - BASIC CONTENS

7/63

99.MP.0056.EN - ASSEMBLING PROCEDURE

8/63

99.MP.0056.EN - ASSEMBLING PROCEDURE

IDENTIFICATION OF THE SELECTED FIX MATERIAL FOR ASSEMBLY

SCREW

POZ. METRIC DIMENSION HEAD SHAPE USE FOR JOINT OF THE …

A1 5,5 x 32 mm PAN fix the face to beam profile of the edge segment

B1 3,9 x 6,5 mm PAN fix the rubber sealing on lath F ( doorsill of face )

C1 6,3 x 25 mm PAN fix the upper rail of the lateral door

D1 2,9 x 13 mm PAN fix the plastic caps in rail of the lateral door

RIVET

POZ. METRIC DIMENSION TYPE USE FOR JOINT OF THE …

A2 4 x 10 mm stopper for rails AZURE, connector, limit door stop

4 x 10 mm plastic backstop, end of rails, sealing lath F under faces

B2 4 x 16 mm base of the face arrestment, limit door stop

PLASTIC CAP

POZ. METRIC DIMENSION TYPE USE FOR JOINT OF THE …

A3 D 15 mm colour per rail cover of predrilling hole in ground rails

B3 D 13 mm black cover of predrilling hole for hide of the power cable

RUBBER SEALING

POZ. METRIC DIMENSION TYPE USE FOR JOINT OF THE …

A4 height 100 / 120 mm black mPVC sealing for bottom part of the face = sill

B4 4 x 8 mm black self-adhesive mounting tape under PC in groove of beam profile

FIX THE RAILS TO GROUND

( type of the fix material depend on basement type )

POZ. METRIC DIMENSION HEAD SHAPE USE FOR JOINT OF THE …

A5 6,3 x 32 mm PAN fix to wooden - standard

B5 8 x 60 mm raw plug fix to concrete - standard

PREPARE JOBSITE

ITEM

ASSEMBLING INSTRUCTIONS FOR ENCLOSURES

1

4

8

11

16

15

2

5

7

12

17 18 19

13

20

14

21 22

24

23

25 26

3 6

10

9

TOOLS FOR ASSEMBLY - RECOMMENDED

05

01

14

10

23

19

06

02

15

11

24

20

07

03

16

12

25

21

08

09 18

04

17

13

26

22

Soft pads

Vacuum cleaner

Dust - brush

Screwdriver bits

Cord - extension set

Hammer

Level ruler

Screwdriver - cross ( small / large )

Measuring tape

Steel band

Knife

Pencil color mark

Rivet pliers

Tongs

Metal saw

Scissors for edit of rubber sealing

Set - socket wrench

Accumulator screwdriver

Dril ( 4 ; mm; 6,2 ; 7mm )Ø mm Ø 5 Ø mm Ø Small flat pliers

Drill to concrete ( ; mm )Ø 8mm Ø 15

Pneumatic hammer

Flat pliers

Rubber soft hammer

File ( round / flat )

Screwdriver - flat ( small / large )

10 / 63

99.MP.0056.EN - ASSEMBLING PROCEDURE

ELECTRICAL SUPPLY CONNECTION ENSURE AN ACCESS TO A POOL

This informations may not be corresponding with technical drawing / assembling documentation.

POSITION OF THE LARGEST ELEMENT

DIRECTION OF MOVEMENT OF THE ENCLOSURE

USUALLY PARKING POSITION OF THE ALL SEGMENTS TOGETHER

CLARIFY A POSITION OF THE ENCLOSURE - LARGEST SEGMENT - PARKZONE

11 / 63

99.MP.0056.EN - ASSEMBLING PROCEDURE

THESE SEVERAL BASIC STEPS GOING TO FOLLOW BEFORE ASSEMBLING PROCEDURE

PREPARING THE ASSEMBLY PLACE

MINIMAL TIME FOR ASSEMBLY

12 / 63

99.MP.0056.EN - ASSEMBLING PROCEDURE

PREPARING OF THE RAILS ON THE ASSEMBLY PLACE

Prepare the rail for connection the parts of rail along total lenght of the rail

Put the sole connector into sole chamber of the rail, so that connector

will be protrude with one half from total length of connector.

CLEANING THE ASSEMBLY PLACE

Assembling of the enclosure is made on

stabilized, plain, level and clean surface !

Clean the surface around the pool, especialy the

places, where the rail will be fixed

STEP - 1

STEP - 1 STEP - 2

13 / 63

99.MP.0056.EN - ASSEMBLING PROCEDURE

FIX MATERIAL

RIVET 4x10 mm A2

( 1 CONNECTOR = 1 pce for join of the connector to rail )

Rivet the connection - the same way for left and right rail.

EACH CONNECTOR must be protrude with one half from total length of connector.

1/2

1/2

THE COMPOSE RAILS

THE MONOLITHIC RAIL

ATTENTION! TWO TYPES OF RAIL AZURE ARE AVAILABLE - COMPOSE OR MONOLITHIC !

for eliminate the side shifting of parts of rails.

Both connectors are neccessary to push into edge of chamber of rail

POSITION OF CONNECTORS FOR COMPOSE OR MONOLITHIC RAILS ARE SAME TOO !

2 1

1.AXIS WIDTH

COMPOSE MONOLITHIC

1.AXIS WIDTH

1.AXIS WIDTH

2

2

1

1

OUTSIDE CONNECTOR INSIDE CONNECTOR

STEP - 3

STEP - 4

THE LEFT RAIL THE RIGHT RAIL

D TO ONE PART OF RAILRILL D TO ONE PART OF RAILRILL

ONE PART OF RAIL

WITH RIVETING CONNECTORS

ONE PART OF RAIL

WITH RIVETING CONNECTORS

OTHER PART OF RAIL

WITHOUT CONNECTORS

OTHER PART OF RAIL

WITHOUT CONNECTORS

NO SIDE SHIFTING

FOR BOTH PARTS OF THE RAIL

NO SIDE SHIFTING

FOR BOTH PARTS OF THE RAIL

RIVET OF TWO CONNECTORS INTO ONE PART OF RAIL RIVET OF TWO CONNECTORS INTO ONE PART OF RAIL

CONNECTING THE PART OF RAIL

ALONG TOTAL LENGHT

CONNECTING THE PART OF RAIL

ALONG TOTAL LENGHT

14 / 63

99.MP.0056.EN - ASSEMBLING PROCEDURE

RIVET THE CONNECTION INTO LEFT AND RIGHT RAIL

STEP - 5

STEP - 6

STEP - 7

STEP - 8

MEASUREMENT

THE LEADING LINES

ITEM

ASSEMBLING INSTRUCTIONS FOR ENCLOSURES

INNER WIDTH

BETWEEN RAILS

1.RAILS AXIS WIDTH

THE DISTANCE

FROM AXIS OF THE 1.RIGHT RAIL TO AXIS OF THE 1.LEFT RAIL

LEGEND FOR TECHNICAL DOCUMENTATION / MEASUREMENT

USE

TECHNICAL

DOCUMENTATION

( see for example )

This inner length of enclosure is sum of length of the

pool with minimal sufficient distance from the outer

edgeofthepool.

This width is between and aaxis of the 1.right rail xis

of the 1.left rail. checked by measuring

diagonals too

Must be

!

This total length of rails is longer than is length of

enclosure.

This distance is space between the outer edge of the

pool and inner edge of rail or detachabled face of

enclosure.

Is necessary to keep measuring diagonals too - both

diagonals must have same proportions !

This extension is m necessaryinimal for arrestment of

segment or maximal for parks zone of all segments

outof the pool.

check and measure these dimensions !W, L, A, R, D, DG

After every movement or adjustment the rails again

INNER LENGTH OF ENCLOSURE - L

DIMENSIONS OF POOL - P

These outer dimensions of pool are for assessment of

minimal distance from outer edge of the pool.

INNER WIDTH BETWEEN RAILS - W

This inner width of enclosure is sum of width of the

pool with minimal sufficient distance from the outer

edge of the pool.

1.RAILS AXIS WIDTH - A TOTAL LENGTH OF RAILS - R

DISTANCE - D

DIAGONAL - DG EXTENSION RAIL - PARKZONE

1.RAILS AXIS WIDTH - A

INNER LENGTH OF ENCLOSURE - L

TOTAL LENGTH OF RAILS - R

THE LARGE FIXED

FACE OF ENCLOSURE

THE SMALL FIXED

FACE OF ENCLOSURE

INNER WIDTH BETWEEN RAILS - W

INNER WIDTH BETWEEN RAILS - W

OUTER WIDTH OF RAILS

OUTER WIDTH OF RAILS

16 / 63

99.MP.0056.EN - ASSEMBLING PROCEDURE

total length of rails R

direction of moving with segments off the poolthe

~D8

~D6

L1

inner length of enclosure

L2

inner length of enclosure

W2

inner width

between rails

of pool

outer width of pool

P2

W1

inner width

between rails

outer length of pool

P3

outer length of pool

P4

~D3

~D1

~D4

~D2

~D7

~D5

( - P1) : 2 = D1W1

W1( - P1) : 2 = D2

D1 = D2

( - P3) : 2 = D5L1

L1( - P3) : 2 = D6

D5 = D6

EXTENSION RAIL

FOR PARKZONE

R - L1

R - L2

( 2 - P4) : 2 = DL 7

L 8( 2 - P4) : 2 = D

D= D7 8

( 2 - P2) : 2 = D3W

W( 2 - P2) : 2 = D4

D3 = D4

1

1

2

2

3

3

4

4

CENTRE PER WIDTH DIMENSIONS

CENTRE PER LENGTH DIMENSIONS

USE

TECHNICAL

DOCUMENTATION

USE

TECHNICAL

DOCUMENTATION

17 / 63

99.MP.0056.EN - ASSEMBLING PROCEDURE

3-TH STEP OF MEASUREMENT

4-TH STEP OF MEASUREMENT

ACCURATE CHECK OF THE RAILS AXIS WIDTH

ACCURATE CHECK OF THE DIAGONALS

A2

1.rails axis width

A1

1.rails axis width

1

1

2

2

3

3

4

4

USE

TECHNICAL

DOCUMENTATION

Diagonal DG1

Diagonal DG2 Diagonal DG2

Diagonal DG1

18 / 63

99.MP.0056.EN - ASSEMBLING PROCEDURE

A1

1.rails axis width

DG1

diagonal

DG2

diagonal

A1

1.rail axis width

A2

1.rail axis width

FIXING

THE LEADING LINES

ITEM

ASSEMBLING INSTRUCTIONS FOR ENCLOSURES

UNLEVELNESS OF GROUND

2

1

1

the shifting, first drill and fix the rail on one end.

2.) During the drilling, secure the rail against

1.) Keep perpendicular position of drilling

machine to the rail while drilling

FIRST FIX ONE RAIL BELONG THE LONGER SIDE OF THE POOL, THEN, ACCORDING TO THIS ONE, PROCEED WITH

MEASUREMENT AND PLACING THE SECOND RAIL ON THE OPPOSITE SIDE OF THE POOL.

For wooden floor use spiral dives.

to concrete or pavement surface

Standard r in produce,

usually r are fixed

ails are predrilling

ails

by plastic raw-plugs 8mm - use drill

8mm .

Ø

Ø

Amount of raw-plugs depends on lenght of

rails and especialy on specification of

ground surface.

Important to clean the rails of dirt, the best way is to

use vacuum cleaner and sweep carefully.

Need to underlay the rail

with aluminium strips

FIXING THE FIRST RAIL

BEFORE DRILLING MAKE VISUAL

CHECK TOO, IF THE RAIL IS IN LINE ...

EVENTUALLY POSITION OF THE RAILS

MARKED ON SURFACE FOR CHECK DURING DRILL

PLASTIC RAW-PLUGS Ø8MM

PLASTIC CAPS

20 / 63

99.MP.0056.EN - ASSEMBLING PROCEDURE

STEP - 1 STEP - 2

Table of contents

Popular Lighting Equipment manuals by other brands

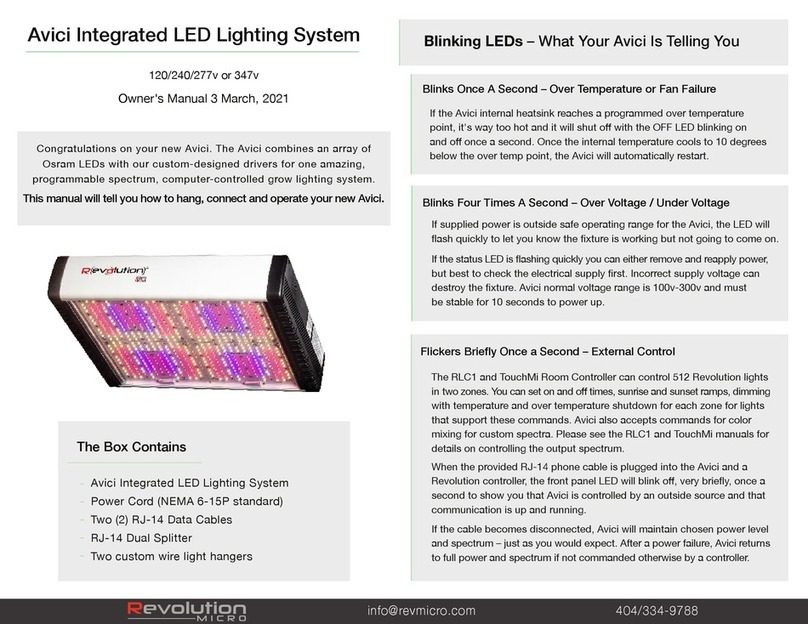

Revolution Micro

Revolution Micro Avici owner's manual

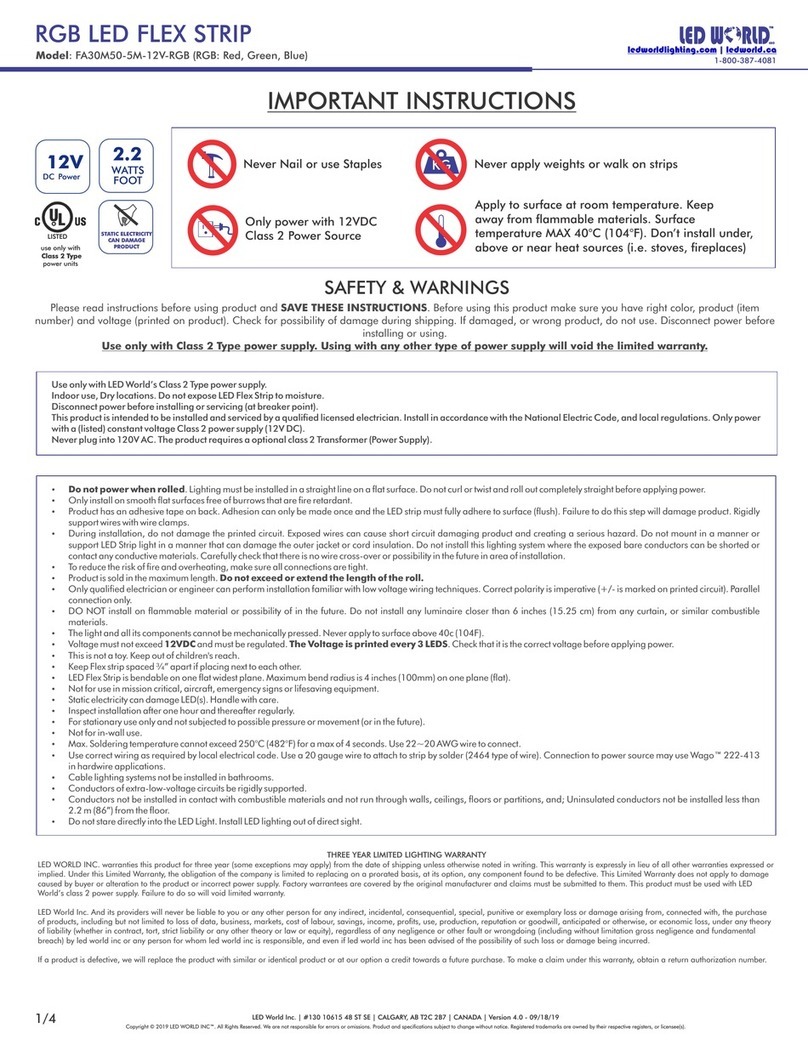

LED World

LED World FA30M50-5M-12V-RGB Important instructions

Chauvet Professional

Chauvet Professional onAir IP panel min user manual

Tranberg

Tranberg TEF 2460 LED user manual

Robe

Robe Anolis Calumma S MC user manual

POWERMOON

POWERMOON POCKETMOON operating instructions