EAS20004

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid

out with the individual steps in sequential order.

•The manual is divided into chapters and each chapter is divided into sections. The current section title

“1” is shown at the top of each page.

•Sub-section titles “2” appear in smaller print than the section title.

•To help identify parts and clarify procedure steps, there are exploded diagrams “3” at the start of each

removal and disassembly section.

•Numbers “4” are given in the order of the jobs in the exploded diagram. A number indicates a disas-

sembly step.

•Symbols “5” indicate parts to be lubricated or replaced.

Refer to “SYMBOLS”.

•A job instruction chart “6” accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc. This step explains removal and disassembly procedure only. For installation

and assembly procedure, reverse the steps.

•Jobs “7” requiring more information (such as special tools and technical data) are described sequen-

tially.

OIL PUMP

5-59

EAS20054

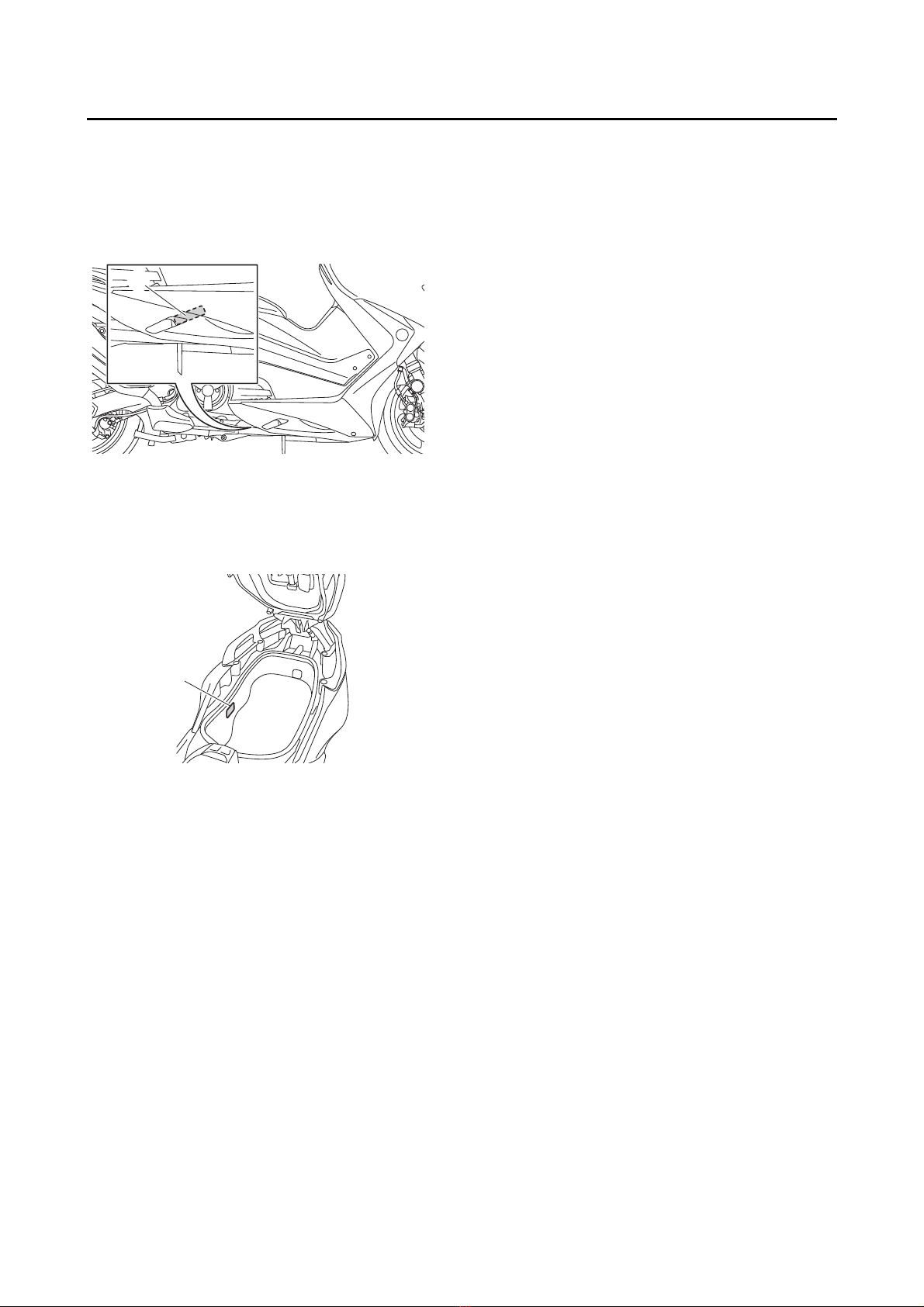

OIL PUMP

Removing the oil pump assembly

Order Job/Parts to remove Q’ty Remarks

Bottom side cowling/Side panel/Bottom center

cowling

Refer to “GENERAL CHASSIS (1)” on page

4-1.

Center cover/Fuel tank cover assembly/Side

cover (left)/Footboard (left)

Refer to “GENERAL CHASSIS (2)” on page

4-11.

V-belt case air filter element (left)/Generator

cover protector/Water pump inlet pipe/Water

pump outlet pipe/Water pump assembly

Refer to “WATER PUMP” on page 6-9.

Generator cover/Generator rotor/Starter clutch

gear

Refer to “GENERATOR AND STARTER

CLUTCH” on page 5-44.

1ylbmessapmupliO1

1niahcevirdpmupliO2

2teksaG3

1epipyreviledliO4

1epipliO5

1ylbmessaevlavfeileR6

(3)

LT

6

5

3

1

2

4

10 N・m (1.0 kgf・m, 7.4 lb・ft)

10 N・m (1.0 kgf・m, 7.4 lb・ft)

OIL PUMP

5-61

EAS30337

CHECKING THE OIL PUMP

1. Check:

•Oil pump driven gear “1”

•Oil pump housing 2 “2”

•Oil pump housing 1 “3”

Cracks/damage/wear →Replace the oil

pump assembly.

2. Check:

•Oil pump operation

Rough movement →Repeat steps (1) and

(2) or replace the oil pump assembly.

EAS30338

CHECKING THE RELIEF VALVE

1. Check:

•Relief valve body

Damage/wear →Replace.

EAS30742

CHECKING THE OIL PIPES

1. Check:

•Oil pipe

•Oil delivery pipe

Damage →Replace.

Obstruction →Wash and blow out with com-

pressed air.

EAS30785

CHECKING THE OIL PUMP DRIVE CHAIN

1. Check:

•Oil pump drive chain

Cracks/stiffness →Replace the oil pump

chain and oil pump assembly as a set.

EAS30342

ASSEMBLING THE OIL PUMP

1. Lubricate:

•Inner rotor

•Outer rotor

•Oil pump shaft

(with the recommended lubricant)

2. Install:

•Inner rotors

When installing the inner rotor, align the pins “1”

in the oil pump shaft with the grooves “a” in the

inner rotor.

3. Check:

•Oil pump operation

Refer to “CHECKING THE OIL PUMP” on

page 5-61.

EAS30343

INSTALLING THE OIL PUMP

1. Install:

•Oil pump assembly

ECA13890

After tightening the bolts, make sure the oil

pump turns smoothly.

Recommended lubricant

Engine oil

Oil pump bolt

10 N·m (1.0 kgf·m, 7.4 lb·ft)