Yamaha VMX12 2001 User manual

Other Yamaha Motorcycle manuals

Yamaha

Yamaha XVS1300CU User manual

Yamaha

Yamaha TDM TWIN 900 User manual

Yamaha

Yamaha XV1700PCRC Road Star Warrior User manual

Yamaha

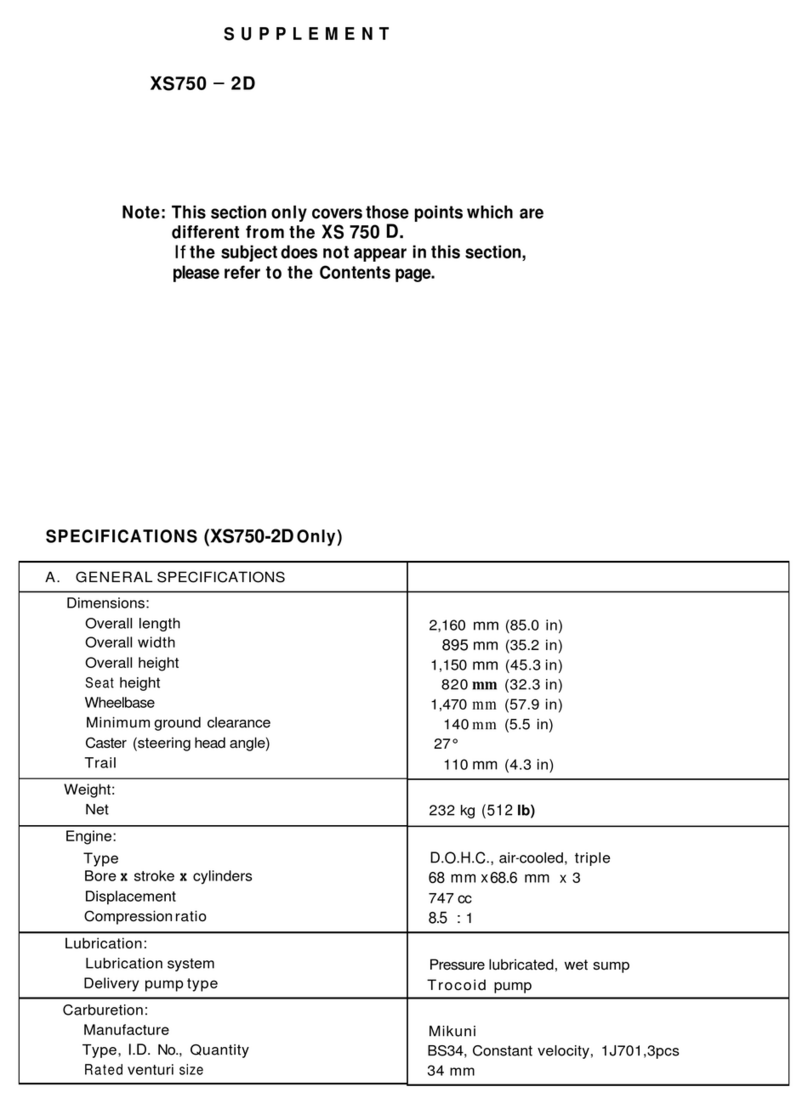

Yamaha XS750-2D User manual

Yamaha

Yamaha SR400 User manual

Yamaha

Yamaha XV1700PCR Road Star Warrior User manual

Yamaha

Yamaha TT-R50E User manual

Yamaha

Yamaha YP400T User manual

Yamaha

Yamaha FJR1300R User manual

Yamaha

Yamaha MT-03 User manual

Yamaha

Yamaha XVS1300A 2007 User manual

Yamaha

Yamaha YZ85( P) /LC Application guide

Yamaha

Yamaha YZFR7N User manual

Yamaha

Yamaha WR250F(D) Application guide

Yamaha

Yamaha FAZER FZ1-S User manual

Yamaha

Yamaha YT175J 1982 User manual

Yamaha

Yamaha LB50-2AE Chappy User manual

Yamaha

Yamaha XT250W User manual

Yamaha

Yamaha Bolt XVS95CH User manual

Yamaha

Yamaha TT 600 R 1997 Operating and installation instructions