Operation and Function

Refrigerator section

The thermostat button can be set from 1(min.) to 7(max.). A suitable setting must be

found by trial and error. Start by setting the button to 4. Check the temperature, then

adjust the setting upwards or downwards as required. Usually, a temperature of 41°F

(5°C) is recommended for items stored in a refrigerator. To check the temperature,

place a thermometer in a glass of water positioned in the center of the cabinet for 12

hours. An average temperature of 41°F should be found in the center of the cabinet.

Freezer section

Always maintain a correct storage temperature.

The thermostat button can be set from 1(min.) to 7(max.). A temperature of 0°F

(-18°C) is recommended for items stored in a freezer. (Maintaining a temperature lower

than this consumes additional energy.) The temperature in the freezer is displayed on

the thermometer.

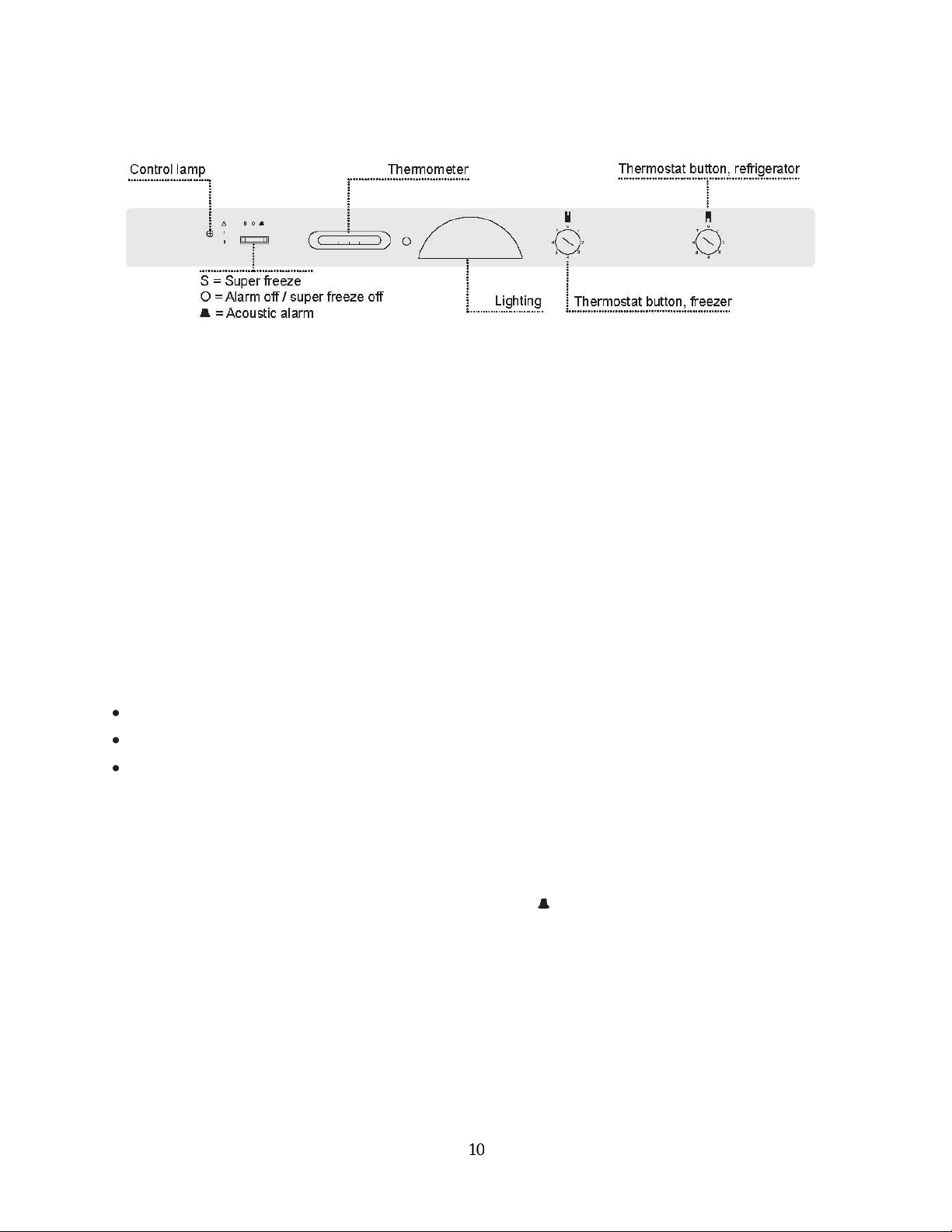

The control lamp lights green when the power supply is connected correctly.

The control lamp lights yellow when Super Freeze is activated.

The indicator lamp lights red and the acoustic alarm sounds if the temperature in the

freezer is too high. To switch off the acoustic alarm, set the freeze button to O(see

fig. 12). The indicator lamp continues to light red as long as the temperature in the

freezer remains too high.

When starting the freezer for the first time, switch off the acoustic alarm by setting the

freeze button to O. Once the recommended temperature (0°F, or -18°C) has been

achieved in the freezer, set the freeze button to the symbol. This will allow the

acoustic alarm to sound if the temperature in the freezer becomes too high.

It is normal that the indicator lamp lights red when the freezer is started for the first time.

It will also occasionally light red when large quantities of fresh material are put in the

freezer simultaneously.