WOODSIZECONVERSIONCHART

NominalBoardSize ActualSize

1" x 4".................3/4" x 3-1/2" (1,9 x 8,9 cm)

2" x 4"..............1-1/2" x 3-1/2" (3,8 x 8,9 cm)

2" x 3"..............1-1/2" x 2-1/2" (3,8 x 6,3 cm)

1" x 3".................3/4" x 2-1/2" (3,8 x 6,3 cm)

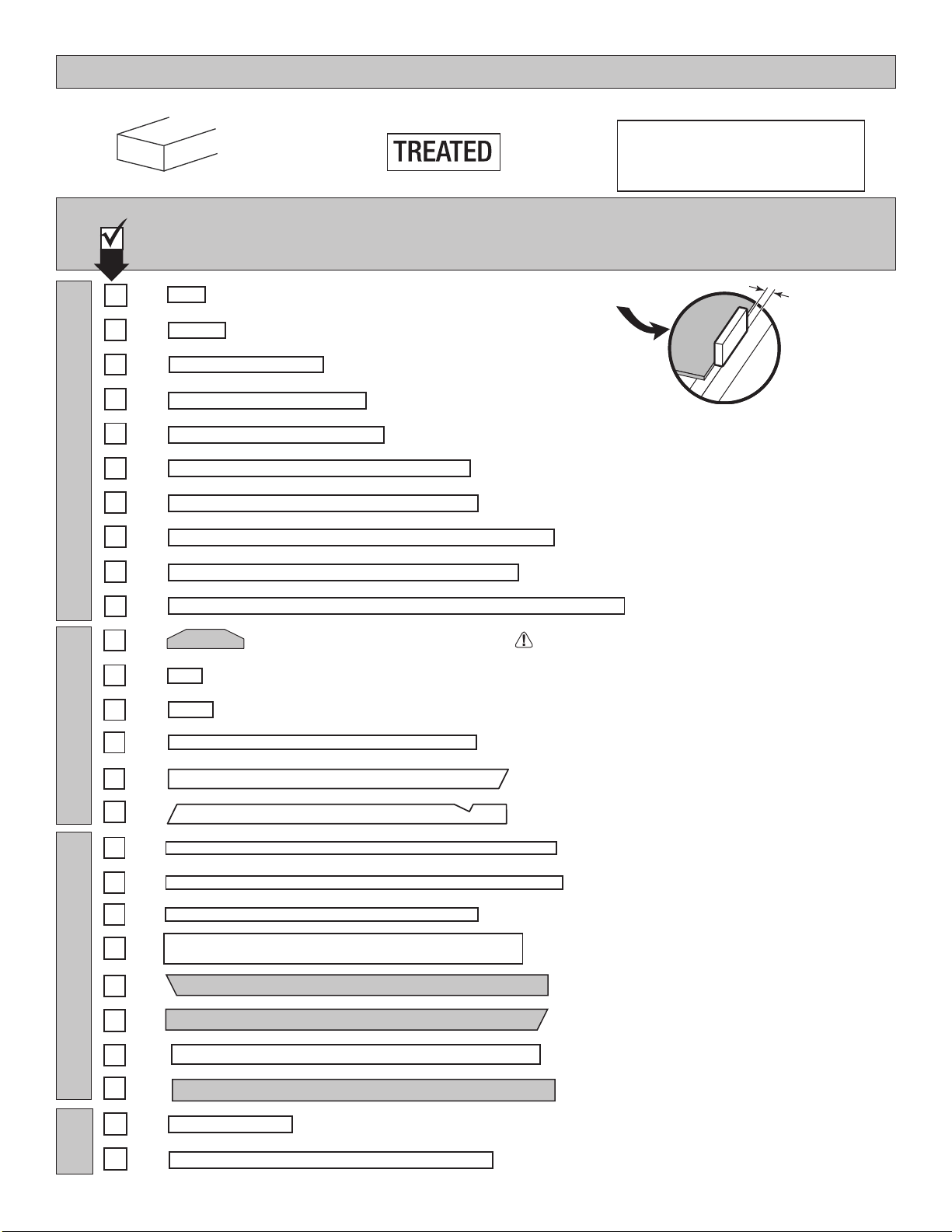

PARTS IDENTIFICATION AND SIZES

RS RS

Part identication

letters are stamped on some parts.

Check these locations for

part stamp.

Treated lumber is stamped:

WALLS

x2 2 x 4 x 80-1/2" (5,1 x 10,2 x 204,5 cm)

CGA

x27 2 x 4 x 80" (5,1 x 10,2 x 203,2 cm)

TK

x4 2 x 4 x 68-1/2" (5,1 x 10,2 x 174 cm)

YFA

x2 2 x 4 x 67" (5,1 x 10,3 x 170,2 cm)

AM

x4 2 x 4 x 48" (5,1 x 10,2 x 121,9 cm)

SP

x2 2 x 4 x 44-1/2" (5,1 x 10,2 x 113 cm)

STL

PARTS LIST

INVENTORY YOUR PARTS before you begin.

We suggest sorting parts by the category they are listed in.

RAFTERS

TRIM

x3 2 x 4 x 8-1/2" (5,1 x 10,2 x 21,6 cm)

CPA

x4 3/8 x 1-3/4 x 81-7/8" (1,0 x 4,4 x 208 cm)

x4 2 x 4 x 96" (5,1 x 10,2 x 243,8 cm)

TP

(1,9 cm)

1 x 3 x 5" (2,5 x 7,6 x 12,7 cm) Gauge Block for 3/4" (1,9 cm) measurement

x1 GAA

DOOR

OO

x2 1-1/2 x 2-1/2 x 69" (3,8 x 6,3 x 175,3 cm)

4

x10 6 x 24" (15,2 x 61 cm) OSBORWOODGRAIN

x10 2 x 4 x 75-1/4" (5,1 x 10,2 x 191,1 cm)

ECN

19/32 x 3 x 72" (1,5 x 7,6 x 183 cm)

x1 ZJ

1 x 3 x 72" (1,6 x 7,6 x 182,9 cm)

x1 HJ

x4 19/32 x 3 x 26-5/8" (1,5 x 7,6 x 67,6 cm)

AH

x4 3/8 x 7-7/8 x 73-5/16" (1 x 20 x 186,2 cm)

x4 3/8 x 5-7/8 x 72-3/4" (1 x 14,9 x 184,8 cm)

x2 3/8 x 4-3/4 x 75-7/8" (1 x 12,1 x 197,2 cm)

x2 3/8 x 4-3/4 x 75-7/8" (1 x 12,1 x 197,2 cm)

x4 3/8 x 4-3/4 x 80-5/8" (1 x 12,1 x 204,8 cm)

x4 2 x 4 x 5-7/8" (5,1 x 10,2 x 14,9 cm)

PVA

x16 2 x 4 x 4-7/8" (5,1 x 10,2 x 12,4 cm)

CLA

x8 2 x 4 x 75-1/4" (5,1 x 10,2 x 191,1 cm)

ECA

x4 3/8 x 1-3/4 x 82-1/2" (1,0 x 4,4 x 209,6 cm)

x2 2 x 4 x 32-1/2" (5,1 x 10,2 x 82,5 cm)

QS