10 ENGLISH

ø 65 mm

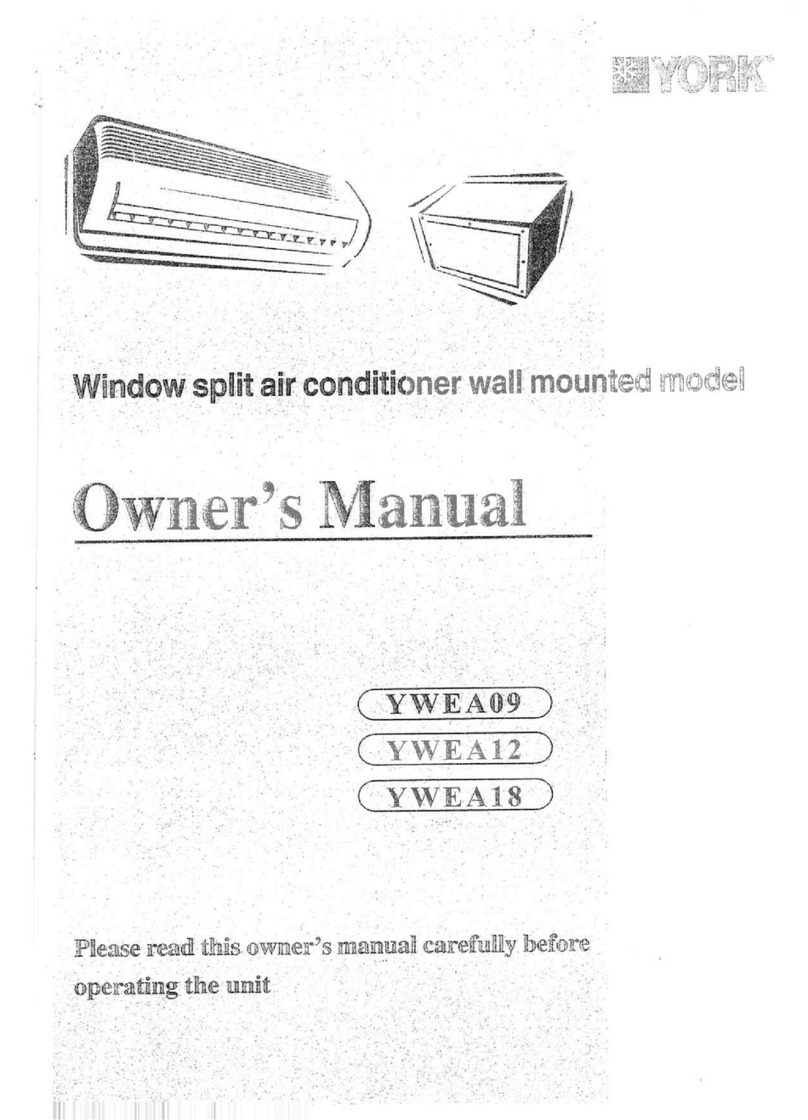

PARTS INSTALLATION

Mounting screw B

ST3.9x10-C-H

Remote controller

holder

Loop the

connective

cable.

8

9

Remote Controller

7

C

B

A

60 cm or more

30 cm or more

60 cm r

oe

r

o

m

200 cm or more

6

2

3

1

12cm or

more

12cm o r

more

Air Filter

15cm or more

Air Outlet

300 cm ormore

On/O

Sleep

Fan

Swing

AirDi rect ion

Timer On

Timer O

Mode

Hr.

ON TIMER

Hr.

O TIMER

SET TEMP

Auto

INDOOR UNIT

INSTALLATION PROCEDURE

Fixing

• Place the installation guide pattern on the designated

installation place and mark the hole position.

• Drill a hole and mount installation plate.

MODEL 09-18

•

Make 6 mm 4-6 holes, in the wall at the four corners of mount-

ing

plate (bracket) then insert appropriate mounting devices.

• Install the mounting plate using 4-6 pieces of mounting screw

securely at four corners and tighten the screw completely.

Do not over tighten the screws and deform the back plate.

• Ensure that the space around the left and right of the

indoor unit is more than 12cm.

The indoor unit should be installed allowing a minimum

clearance of 15cm from the ceiling.

•

Use a stud nder to locate studs to prevent unnecessary

damage to the wall.

• Aminimum pipe run of 3 metres is required to minimise

vibration & excessive noise.

Theindoorunitshouldbeinstalledonthe wallata height

of 1.7 metres or more from the oor but less than 2.3

metres from the oor.

•

Directions A, B and C should be free from obstructions.

• This illustration is for explanation purposes only.

• Copper lines must be insulated independently.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

• After determining the pipe

hole position. Drill the hole

at a slight downward slant

towards the outdoor side.

Outdoor

Indoor

Note: When installing

the refrigerant pipes from

others side. A hole must

be place to allow fall

towards the outdoor unit.

Except the above parts provided, the other parts needed

during installation you must purchase.

NOTES

CAUTIONS

Number

Name of Accessories

11

82

38

14

15

6

Connecting

pipe

Assembly

Liquid side ø 6.35 (7000-18000 Btu/h)

Parts you

must

purchase

Gas side

ø 9.53 (7000-9000 Btu/h)

ø 12.7 (12000-18000 Btu/h)

17

19

NOTES

65

70 70

45

0

7

2

Indoor unit outline Installation plate

A:780 (<16000Btu/h model), 920 ( f16000Btu/h model)

120 mm or

more to wall

120 mm or

more to wall

Left refrigerant

pipe hole Ø65

Right refrigerant

pipe hole Ø65

150 mm or more to ceiling

J440-EN.indd 10 2/14/08 1:26:41 PM

2

Q’ty

Installation plate

Clip anchor

Self-tapping screw AST3.9X25

Seal

Drain joint

Remote contoroller

Self-tapping screw B ST3.9X10

8

Remote Controller holder