INDEX

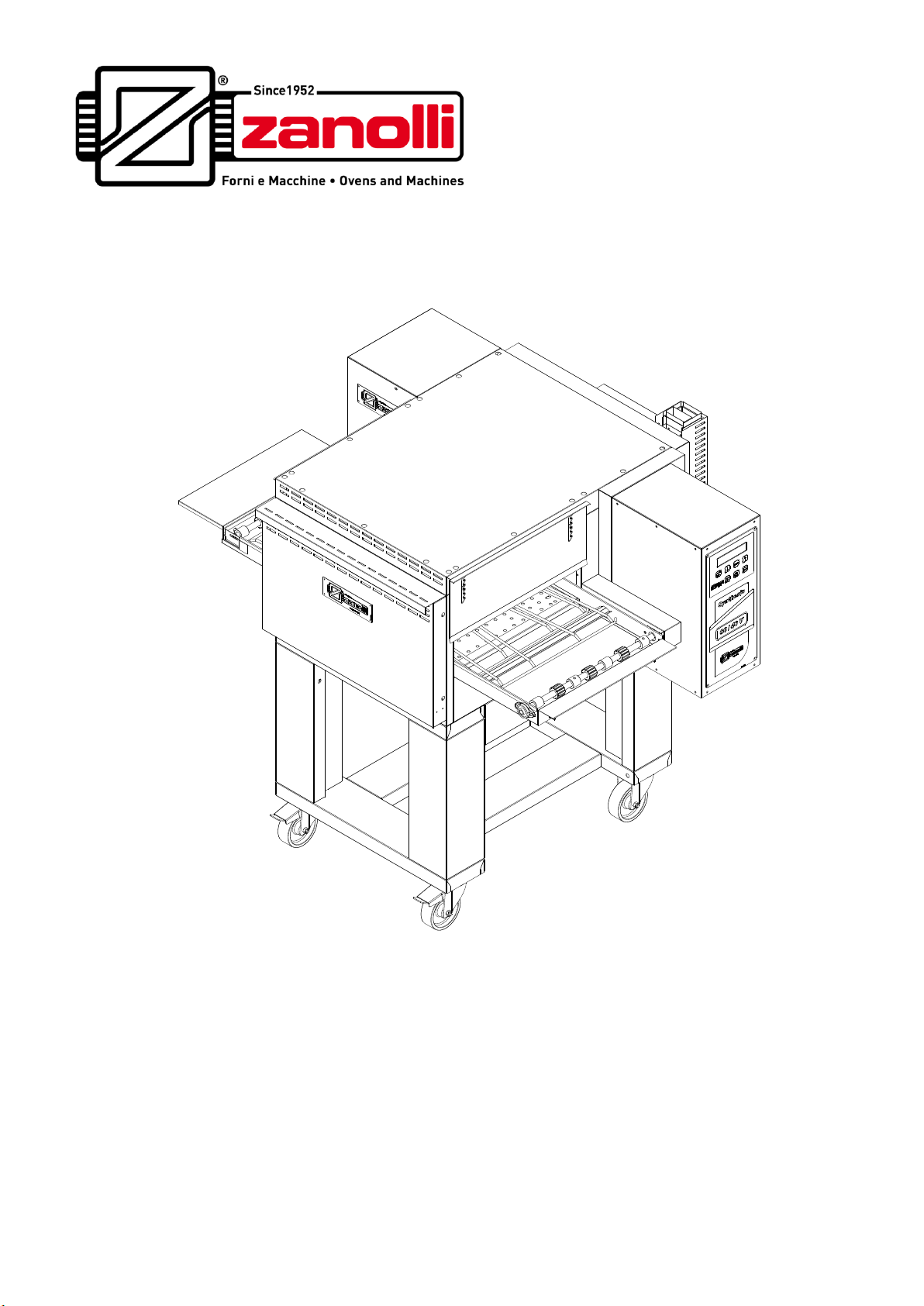

3Synthesis 06/40V GAS

INDEX

1.INTRODUCTION.......................................................................................................5

2.HOW TO USE THIS MANUAL...........................................................................6

3.SPECIFICATIONS...................................................................................................8

3.1 PRODUCT IDENTIFICATION............................................................8

3.2 DIRECTIVES COMPLIANCE.............................................................8

3.3 FORESEEN RANGE OF USE ...........................................................8

3.4 TECHNICAL SPECIFICATIONS........................................................9

4.INSTALLATION......................................................................................................11

4.1 CHECKING ON DELIVERY.............................................................11

4.2 CHOOSING A PLACE FOR INSTALLATION..................................11

4.2.1 Location specifications for the installation of gas ovens............12

4.3 MOVING THE UNIT........................................................................12

4.4 POSITIONIG THE UNIT ON ITS BASE...........................................13

4.5 POSITIONING STACKED UNITS....................................................13

4.6 ELECTRICAL CONNECTION..........................................................13

4.7 CONNECTING THE GAS ................................................................14

4.8 EXHAUST PRODUCED BY COMBUSTION ...................................14

4.9 CHECKING BEFORE STARTING WORK.......................................17

5.OPERATION.............................................................................................................18

5.1 CONTROL PANEL ..........................................................................18

5.2 FUNCTIONAL STATES OF THE SYSTEM .....................................19

5.2.1 Main on/off switch.....................................................................19

5.3 SETTINGS.......................................................................................20

5.3.1 Temperature adjustment..........................................................20

5.3.2 Cooking time adjustment................................................................20

5.4 PROGRAMMING.............................................................................21

5.4.1 Setting the current time.............................................................22

5.4.2 Setting the language.................................................................22

5.4.3 Programming of switching on....................................................23

5.5 SWITCHING OFF THE OVEN ........................................................24

5.6 ALARMS..........................................................................................24

5.6.1 “OVER 1” ..................................................................................24

5.6.2 “OVER 2” ..................................................................................24

5.6.3 “OVER” .....................................................................................25

5.6.4 “BELT” ......................................................................................25

5.6.5 “FAN” ........................................................................................25

5.6.6 “PRESS” ...................................................................................25

5.6.7 “FLAME” ...................................................................................26

5.6.8 "BATTERY"...............................................................................26

6.USE................................................................................................................................27

6.1 PREPARATION FOR USE AND BEFORE TURNING.....................27