6

Mod. CINEA CANALIZÁVEL rev 00

Introduction

translated from the original text

IT IT

FR FR

ES ES

EN EN

• It is forbidden to operate the product with the door

open or the glass broken.

•Do not stay a long time in front of the product while run-

ning. Do not overheat the room where you stay or where

the product is installed.This could harm your physical con-

ditions and cause health issues.

•The product must be stored in humidity-free rooms and

not exposed to weather conditions.

•Do not remove the feet for setting the product body on

the oor to guarantee proper insulation, especially for

oors made of ammable materials.

•Place a oor protection plate as a base for the product if

the oor is made of ammable material, such as parquet

or carpets. (considering that the plate must extend be-

yond the front of the stove by at least 25/30cm).

• It is strictly forbidden to use flammable liquids to light

the fi e; the pellets light automatically when the stove

is on.

•Extraordinary maintenance operations must only be car-

ried out by authorised and qualied personnel.

•For seasonal use of the stove, in case of improper draught

or adverse weather conditions (temperatures < 0°C), make

sure that the uid is perfectly insulated and not obstruct-

ed to avoid freezing or the backow of ue gas.

•If the ue catches re, immediately switch o the product,

unplug it and never open the door. Then call the compe-

tent authorities.

•As the product has an air consumption necessary for com-

bustion, it is recommended to connect the product to the

outside by means of suitable piping reaching the specic

inlet at the back of the stove.

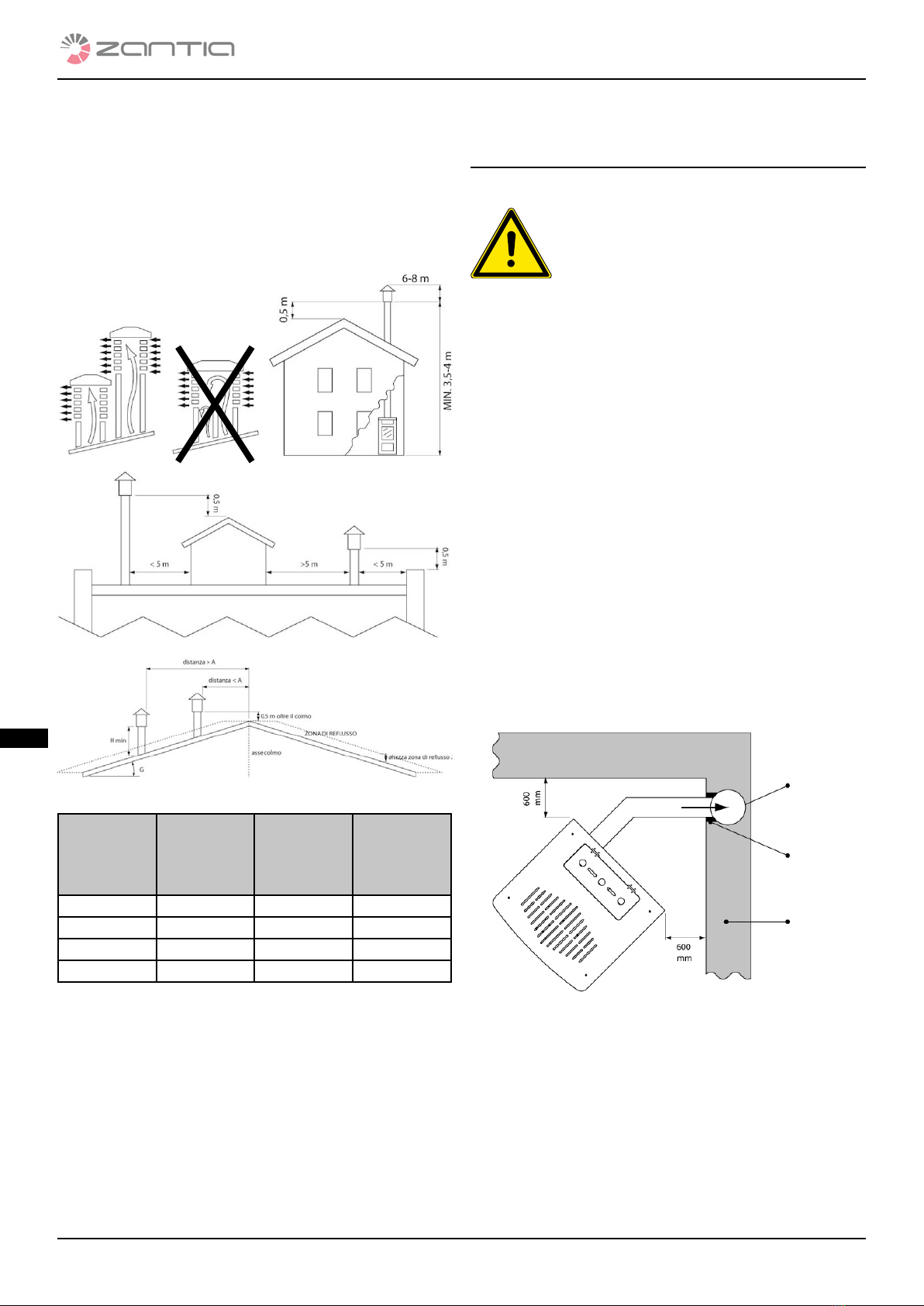

•For safety purposes, it is recommended to maintain at least

20 cm between the hot sides of the stove and any amma-

ble cover materials (e.g. matchboarding walls, wallpaper

etc.) or to use specic insulating materials available on the

market. This assessment must also be made regarding fur-

niture, armchairs, curtains and similar objects.

•To facilitate technical support interventions, do not recess

the product in tight spaces, do not push it against the wall

as this could jeopardize correct ventilation.

• The absence of draught by the flue (or e.g. the obstruc-

tion or closing of brazier air inlet or of the brazier it-

self) alters functioning of the stove which, during the

automatic ignition phase, could cause too many pel-

lets to be dispensed into the brazier due to delayed

sparking of the fi e. Too much smoke in the combus-

tion chamber could cause the flue gas to light with a

sudden blaze. In this condition never open the door of

the combustion chamber.

•The pellets feeding the product must have the characteris-

tics described in this manual.

•Do not leave children alone near the stove while it is lit, as

all the hot parts could cause serious burns.

•Do not carry out any operation on the stove other than

those indicated for its regular use or those recommended

in this manual to solve simple problems. Always unplug

the appliance before intervening and only operate with

the stove cold.

•IT IS absolutely prohibited to remove the pellet tank pro-

tective grid.

•Always check and make sure that the door of the combus-

tion chamber is hermetically closed during ignition and

operation of the stove.

•Automatic ignition of the pellets is the most delicate

phase. It is recommended to always keep the product and

brazier clean so that it can be done without any problems.

•In the presence of operating faults, the product can only

be switched back on after having solved the cause of the

problem.

•Zantia is not liable for inconvenience, tampering

with, damage, or whatsoever due to failure to comply with

the provisions provided in this manual.

•This booklet is an integral part of the appliance; therefore,

it must be stored and accompany the device in case of

transfer of property.

•This appliance is not intended for use by persons (includ-

ing children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concern-

ing use of the appliance by a person responsible for their

safety.

•Only use the fuel recommended by the manufacturer. The

product cannot be used as an incinerator. It is strictly

forbidden to use liquid fuels.

•To correctly use the product and the electronic equipment

connected to it and to prevent accidents, always observe

the indications provided in this manual.

•Before starting any operation, the user or whoever is op-

erating the product must have fully read and understood

this installation and use manual. Errors or improper set-

tings can cause dangerous conditions and/or irregular

operation.

•Switch the product o in case of failures or malfunction-

ing.

• The buildup of unburned pellets in the burner after

each "failed ignition and alarm" must be removed be-

fore attempting another ignition. Check that the burn-

er is clean and well positioned before switching it back

on.

•Do not wash the product with water. Water could inltrate

into the unit and damage the electric insulations, causing

electrical shocks.

•Install the product in rooms which are not re hazards and

are set up with all services such as supplies (air and elec-

tric) and ue gas exhausts.

•Do not stand on the product or use it as a support struc-

ture.

•Do not dry sheets on the product. Drying racks or similar

products must be kept a safety distance from the product.

There is the risk of fi e!

• All responsibility for the improper use of the product is

fully borne by the user and releases the manufacturer

from all civil and criminal liability.

•In case of failure to the ignition system, do not force igni-

tion by using ammable materials.

1.5 WARRANTY TERMS AND CONDITIONS

1. The Manufacturing Company guarantees the structure

and materials making up the product for a period of 24

months from the date of purchase, as long as the pur-

chaser sends the attached sheet within 8 days of the

date of delivery, completely lled out and keeps a copy