HW SERIES SURGE PROTECTORS

Custom Surge protection is our specialty. Custom versions are available including mixed or

special voltages, different connectors or wiring options. Contact us for details.

OPERATION:

The Zap-Tech protector will repetitively protect and reset without

degradation up to it's maximum repetitive self-reset surge. If it is

subjected to more than it's maximum repetitive self-reset surge, the

device will remain in a clamped mode indicating that it should be

removedor replaced while keeping the equipment safe from

subsequent surges.

INSTALLATION:

Zap-Tech protectors should be installed in series with the incoming

communication line at the port of the equipment being protected. The

protector's grounding wire must be connected to the chassis ground

of the protected equipment.

IMPORTANT!

It is important that the protector and the chassis of the equipment to be

protected are both properly grounded to a properly earthed electrical

safety ground via the equipment's 3-prong power cord and/or a ground

wire of 14 AWG or larger. Protectors should be installed at both ends of

communication lines to ensure equipment protection at each end.

All specifications are subject to change without notice.

Detailed specifications for specific versions available on request.

© Copyright 2013, Zap-Tech Corporation all rights reserved.

888-727-1951

www.zap-tech.com

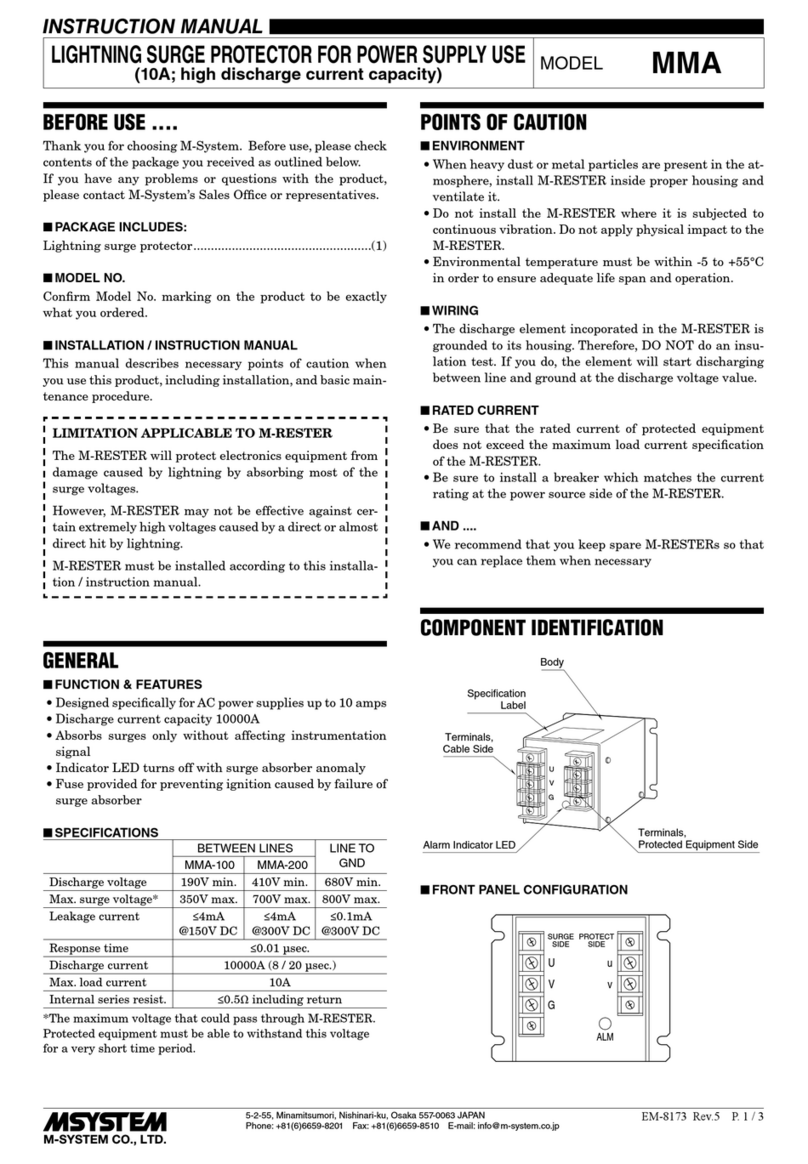

HARDWIRED IN LINE PROTECTOR

SHOWN WITH OPTIONAL DIN RAIL MOUNTING CLIP

HW SURGE ARRESTOR

MODEL HW8-18C

ATTACH GROUND WIRE TO GROUNDED

CHASSIS OF PROTECTED EQUIPMENT

ELECTRICAL SPECIFICATIONS

PART NUMBER SELECTION:

FORMAT: HW4-18C

HW(# of wires)-(clamp voltage)(C for optional DIN Clip)

APPLICATION

MAX

OPERATING

VOLTAGE

MODEL CLAMP

VOLTAGE

RS422, RS423,

RS232, RS485

DIGITAL

CURRENT LOOP

ANALOG

CURRENT LOOP

LEASED LINE,

ISDN, T-1, DDS

DIAL UP,

POTS LINE HW(_)-260

HW(_)-62

HW(_)-27

HW(_)-18

HW(_)-7

260V

7V

5.5V

25.5V

60.0V

250V

62V

27V

18V

16.0V

MAXIMUM REPETITIVE SELF RESET SURGE:

3500 Volts,1750 Amps for 100 pulses using 2 V source.

per: EN61000-4-5 Specification (all lines common mode).

*MAXIMUM FAIL SAFE SURGE (all lines common mode):

4000 Volts 2000 Amps for 100 pulses using 2V source.

per EN61000-4-5 Specification. Exceeds EN6100-4-5, level 4.

CLAMPING VOLTAGES:

Common Mode - Line to line.

Differential Mode - Line to ground.

*CAPACITANCE:

Line/line: <40pF.

Line/Ground: <40pF.

COMPONENT RESPONSE TIME:

Less than 10 Nanoseconds.

OPERATING TEMPERTURE:

(-40ºC TO +85ºC).

*Applies to all devices except 62V and 260V.

MECHANICAL SPECIFICATIONS

1/4” GROUND BRAID, 8.0” (+/-0.25”) INCH

LENGTH, GREEN W/ 10-32 RING TERMINAL.

WIRE ENTRY GROMMET

(BOTH ENDS)

UNIT WITH COVER REMOVED

TO SHOW WIRE INSTALLATION

STRAIN RELIEF ZIP TIES

(BOTH ENDS)

PAIR A: 1,2

PAIR B: 3,4

PAIR C: 5,6

PAIR D: 7,8

PAIR E: 9,10

PAIR F: 11,12

INSTALLATION

11

12

11

12

F

F

PROTECTION PAIRING ASSIGNMENTS:

Just splice the HW series unit

in line with your existing cable.