MISC

Stacked Poles

Not all of the TRRS connectors have tabs. Some of the connectors have

stacked "poles" to solder to. Many of the steps for attaching them are

the same, but the process is a bit dierent. 1

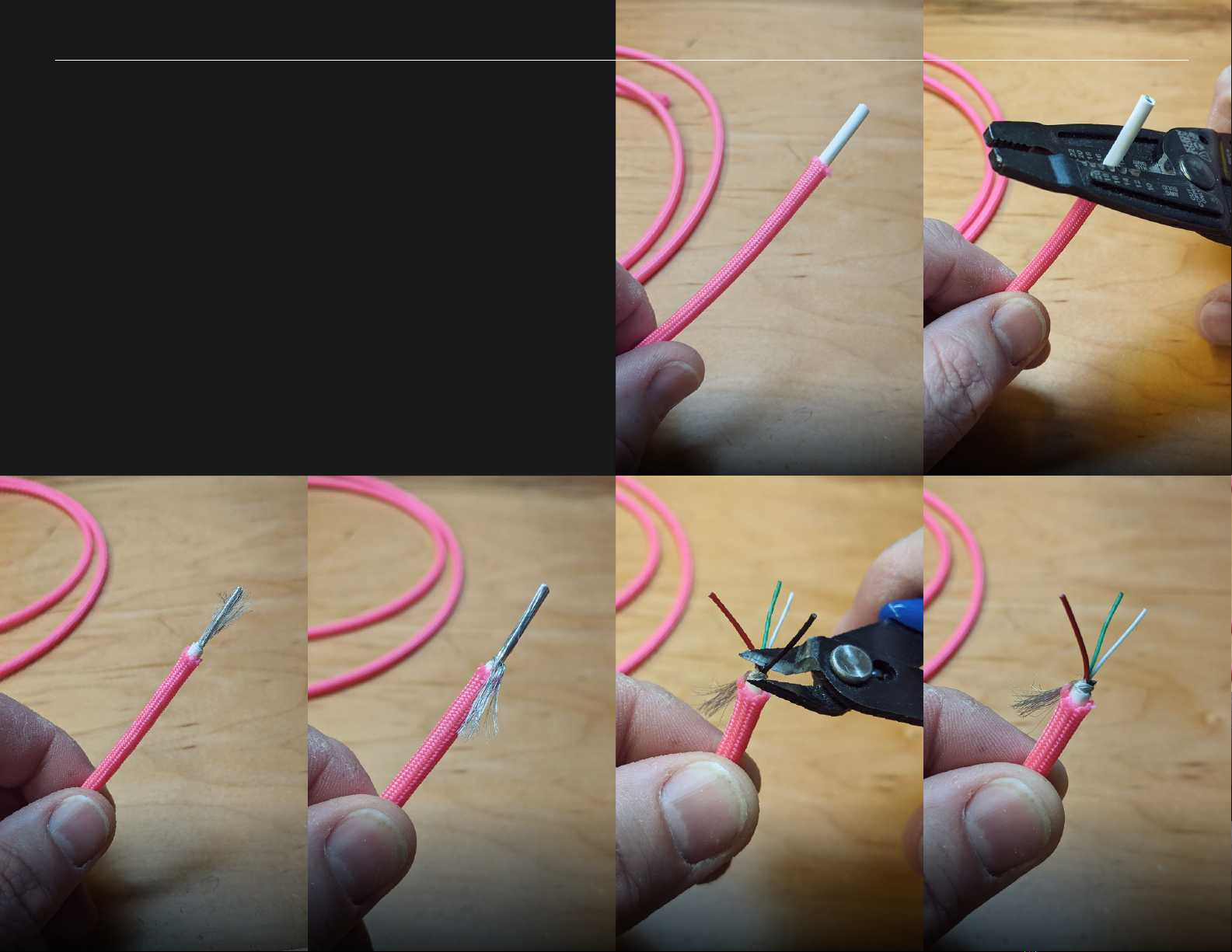

Prep the cable as covered previously.

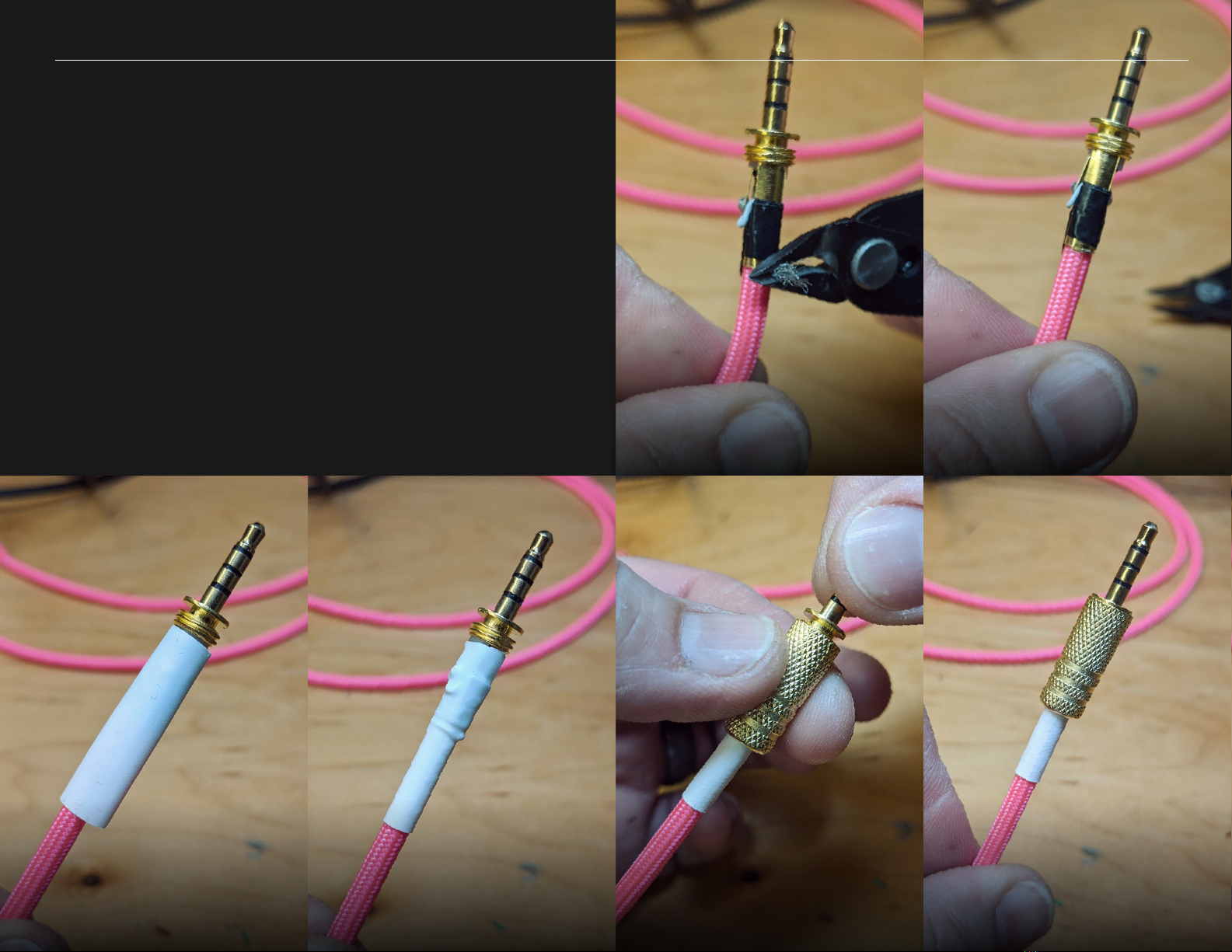

After you slide the barrel and heatshrink

on to the cable (don't forget!), Place

the connector onto the cable with the

clamps making solid contact with the

gathered shielding. The shielding needs

to make physical contact with the clamp

tab for proper shielding/grounding.

3

After you get them all tinned, inspect

your work. Make sure the plastic isn't

covering up the tinned soldering poles.

Cut away any loose "hairs" of melted

plastic.

5

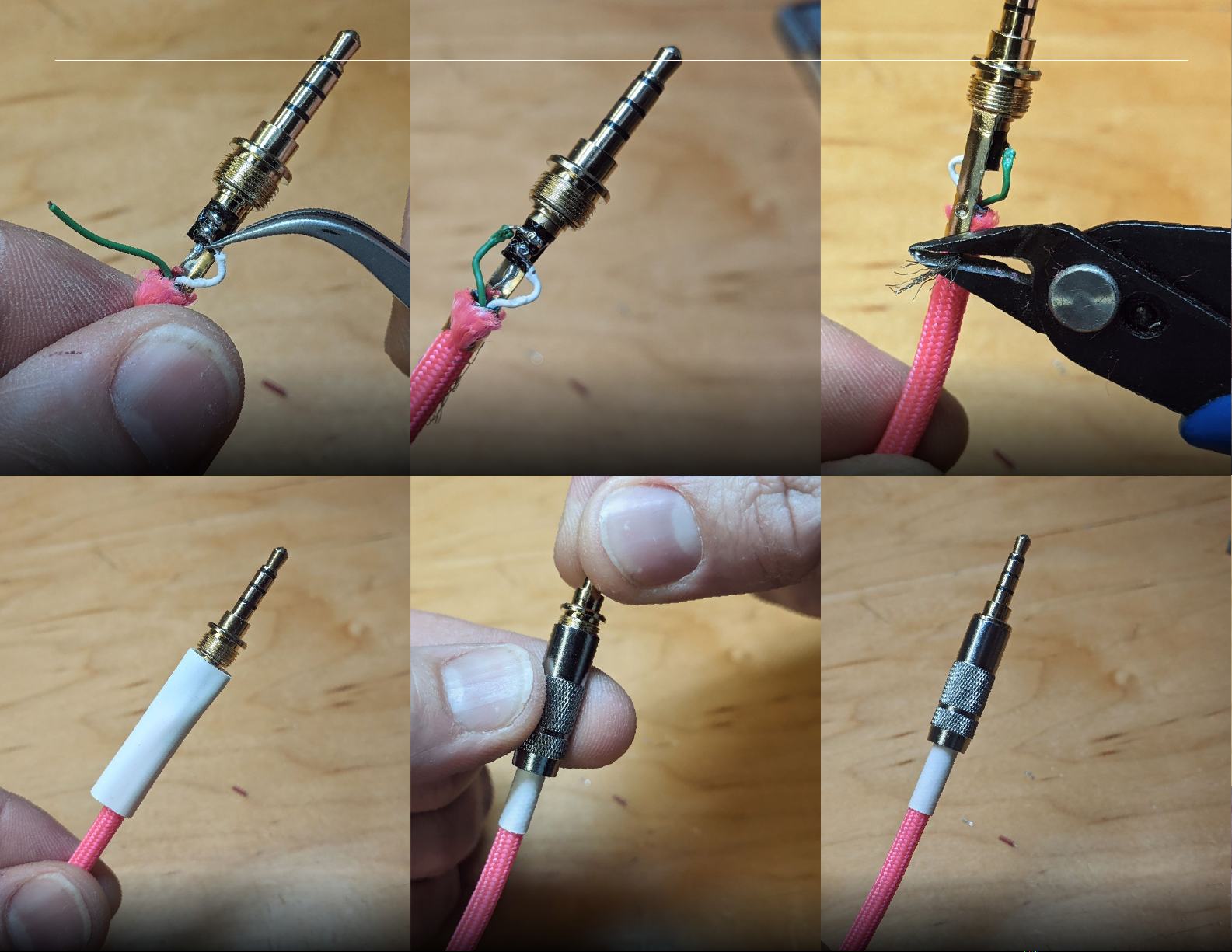

Using tweezers, hold the conductor in

place and solder to pole. Keep in mind

you can heat this bottom pole from the

underside as well.

4

Strip, twist, tin, and trim the first

conductor. Start with the bottom-most

soldering pole. You will likely want to cut

this one relatively short to keep things

tidy. (Longer than shown here is fine.)

6

Inspect your work. This conductor was

worked a bit too much and lost some of

its insulation, but should still function

just fine. Watch out for exposed wire

like this making contact with other

exposed wires.

2

Tin each section of the pole. You will

likely melt some of the black insulation

plastic, but don't worry. Depending

on your soldering iron, the pole-style

connectors may require a higher heat

setting.

The poles are a mirror

image of the plug. The

bottom-most pole

connects to the tip.

Zap Cables Instructional Series DIY TRRS Cable Kit Guide