`çåíÉåíë

fåëíêìÅíáçå=j~åì~ä=`êçëëÄÉ~ã=PQM=ÉåMOE`loF =s

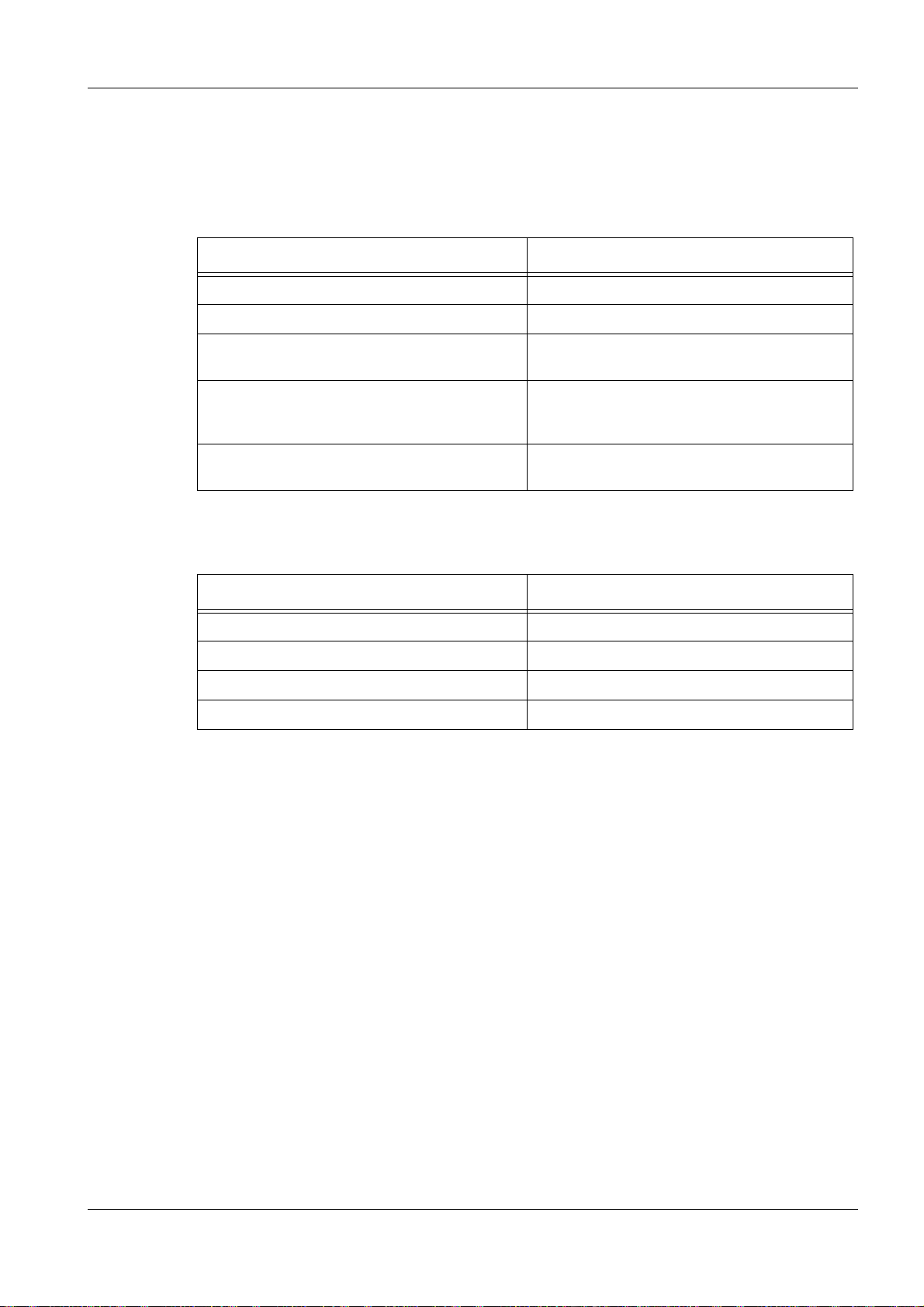

6.5. Changing between vacuum modes .............................................................. 82

6.5.1. Changing to VP mode ........................................................................................... 82

6.5.2. Returning to HV mode ........................................................................................... 82

6.6. Setting SEM parameters ................................................................................ 83

6.6.1. Viewing the probe current ..................................................................................... 83

6.6.1.1. Changing the extractor voltage ..................................................................................... 83

6.6.1.2. Measuring the specimen current................................................................................... 84

6.6.2. Setting detection parameters ................................................................................ 85

6.6.2.1. Selecting a detector....................................................................................................... 86

6.6.2.2. Using the SE2 detector ................................................................................................. 86

6.6.2.3. Using the VPSE detector............................................................................................... 87

6.6.2.4. Using the SESI detector (optional)................................................................................ 88

6.7. Electron beam deposition or etching (with GIS upgrade only) ................. 89

6.7.1. Heating the reservoirs ........................................................................................... 90

6.7.2. Depositing or etching with the electron beam ....................................................... 91

6.8. Crossbeam operation .................................................................................... 92

6.8.1. Preparing the workstation ...................................................................................... 92

6.8.1.1. Getting started............................................................................................................... 92

6.8.1.2. Adjusting tilt eucentricity................................................................................................ 93

6.8.1.3. Switching on the ion beam (FIB)................................................................................... 94

6.8.1.4. Setting the coincidence point ........................................................................................ 97

6.8.2. Gas assisted deposition: Platinum (with GIS upgrade only) ................................. 98

6.8.2.1. Heating the platinum reservoir ...................................................................................... 98

6.8.2.2. Outgassing the platinum reservoir................................................................................. 99

6.9. Using the help functions ............................................................................. 101

6.9.1. Calling the SmartSEM®help window .................................................................. 101

6.9.1.1. Printing help texts........................................................................................................ 101

6.9.1.2. Bringing help texts to the foreground .......................................................................... 101

6.9.2. Calling the context-sensitive help ........................................................................ 101

6.9.3. Searching for a topic ........................................................................................... 102

6.9.4. Using the step-by-step guides ............................................................................. 102

6.9.4.1. Getting started............................................................................................................. 102

6.9.4.2. Frequently used operation sequences........................................................................ 102

6.9.5. Calling the short cuts help ................................................................................... 102

6.9.6. Showing information about SmartSEM®............................................................. 103

6.9.6.1. Version history............................................................................................................. 103

6.9.6.2. About SmartSEM®....................................................................................................... 103

6.10. Finishing the work session ....................................................................... 104

6.10.1. Switching off the EHT ........................................................................................ 104

6.10.2. Logging off from the SmartSEM®user interface ............................................... 104

6.11. Changing to STANDBY mode ................................................................... 105

6.12. Switching off the microscope ................................................................... 106

6.12.1. Changing to OFF mode ..................................................................................... 106

6.12.2. Closing the main shut-off valves ....................................................................... 106

6.13. Switching off the microscope in an emergency (EMO) .......................... 107