3.1 A concrete pad forms an excellent base for your tub.

A properly poured 4” reinforced pad will be stable and

resistant to frost heave. Size the pad so that the sides are

about as long as the diameter of the tub. Example: For a

tub 6’ in diameter, pour a 6’ x 6’ pad.

3.2 A gravel pad can be a simple foundation for a tub in

some cases. If the ground on the site is compact and

stable soil, sand, gravel or rock; a layer of pea gravel (or

course sand) on top can be used to establish a level

foundation for your tub. However, if the soil is unstable,

soft, duffy or muskeg, a gravel pad will settle unevenly

under the weight of the tub and is not a good choice. If

you choose a gravel pad, make it larger than the diameter

of the tub by about 3 feet. Example: For a 6’ tub, make

the pad 9’ in diameter. The thickness can vary depending

on how much gravel is needed to level the site.

Typically, 2 to 4 inches is sufficient. Smooth with a rake

and check with a carpenter’s level.

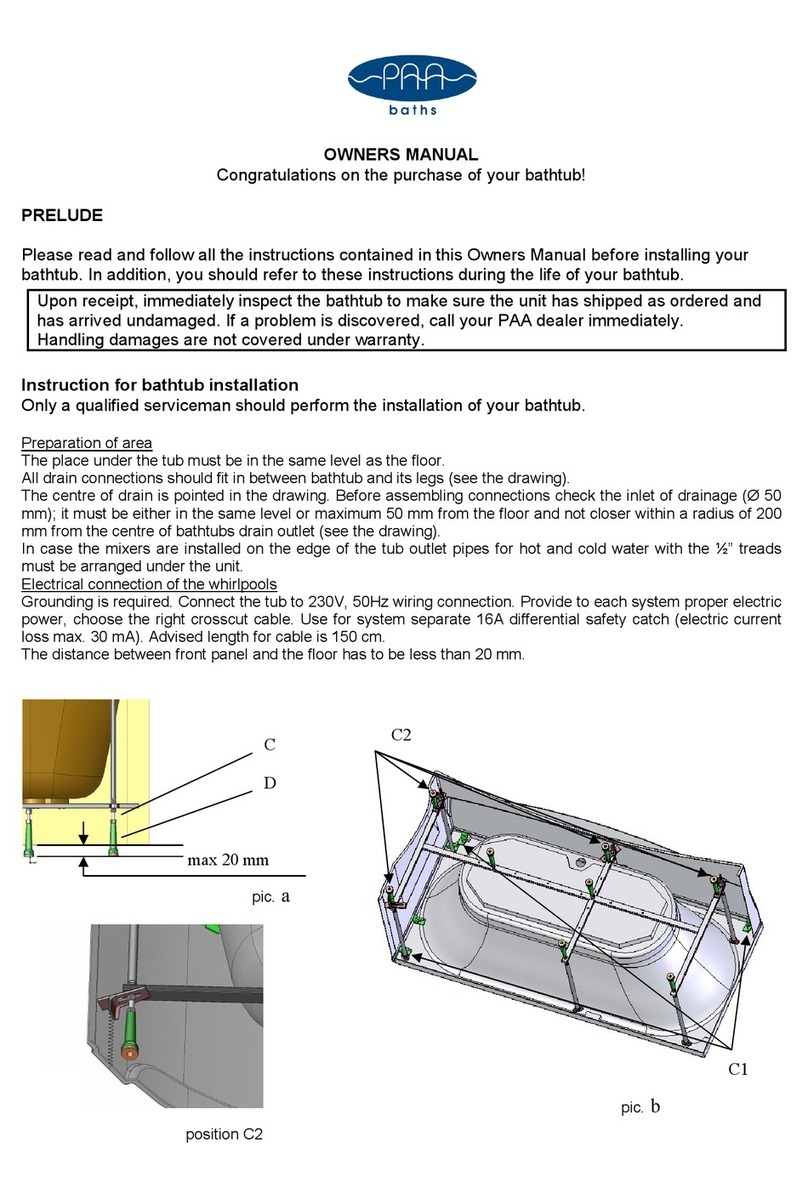

3.3 Another alternative is to use adjustable concrete pier

blocks as a foundation. This type of pier block is

available at most home improvement stores and allows

you to adjust the level of the tub after it is in place. Piers

can be set into the ground to make a solid foundation for

the tub. This method involves building a small but strong

wooden frame or cribbing to support your tub.

Typically, four piers should be used, and the wood

timbers should be 4” x 6” or bigger. The bottom of the

piers must rest on stable material. See Figure 3.3 for an

example.

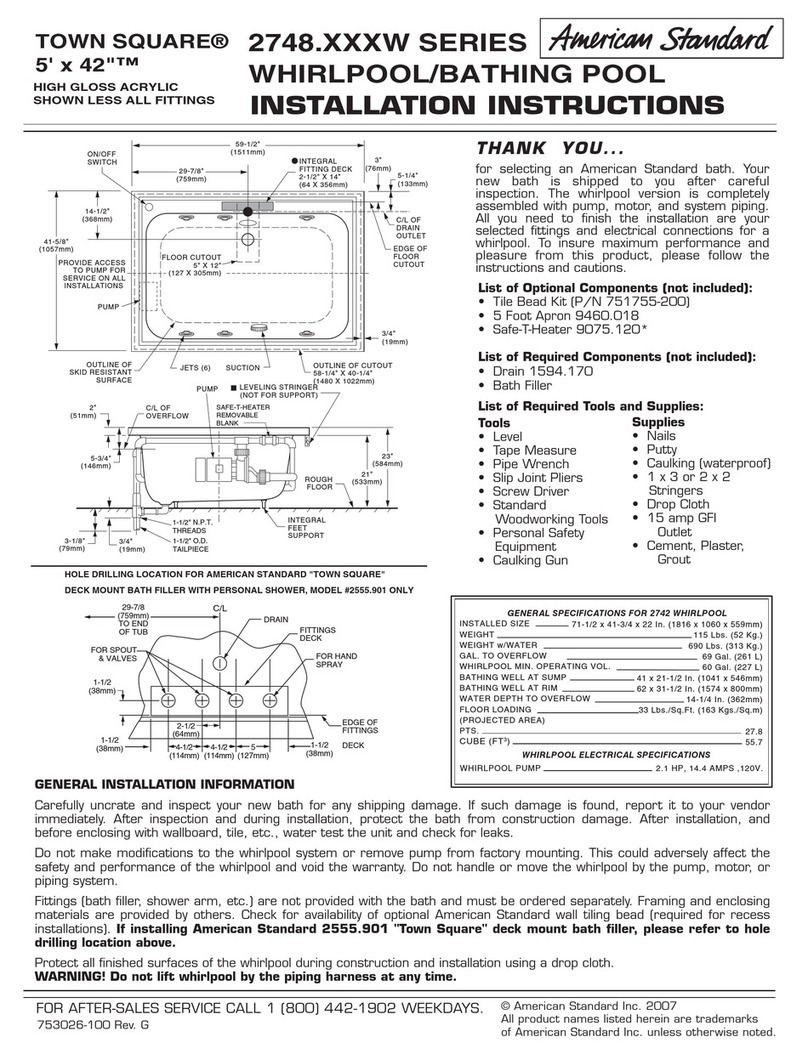

Figure 3.3 Pier block foundation

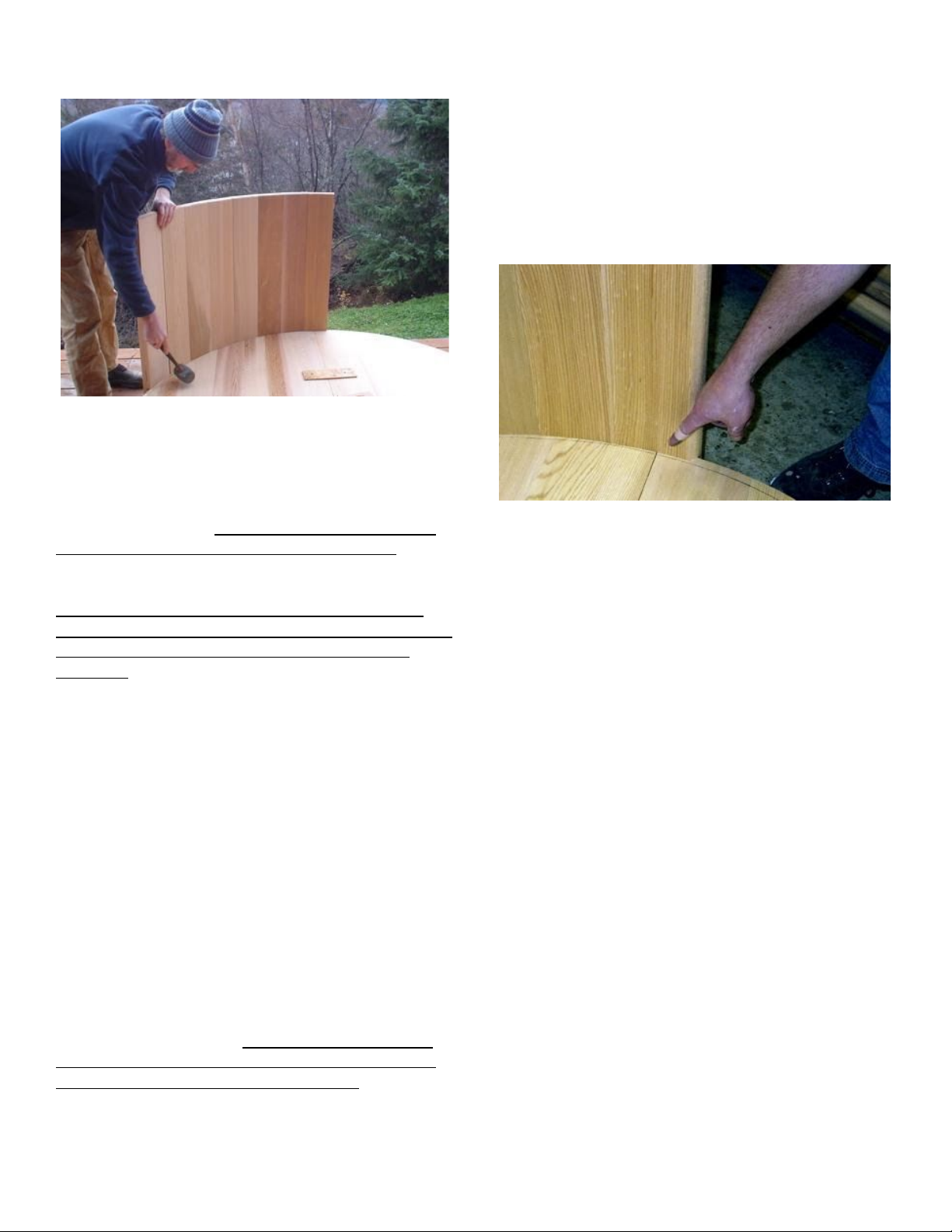

3.4 Another option is to install the tub on a deck.

Installation on a wooden deck can be a good choice.

Be sure that your deck has been designed to support

the weight of a full tub (1500 - 8000 lbs. depending

on the size of the tub). Have the deck inspected by a

qualified architect or building engineer prior to

proceeding. See Figures 3.4 for deck installation.

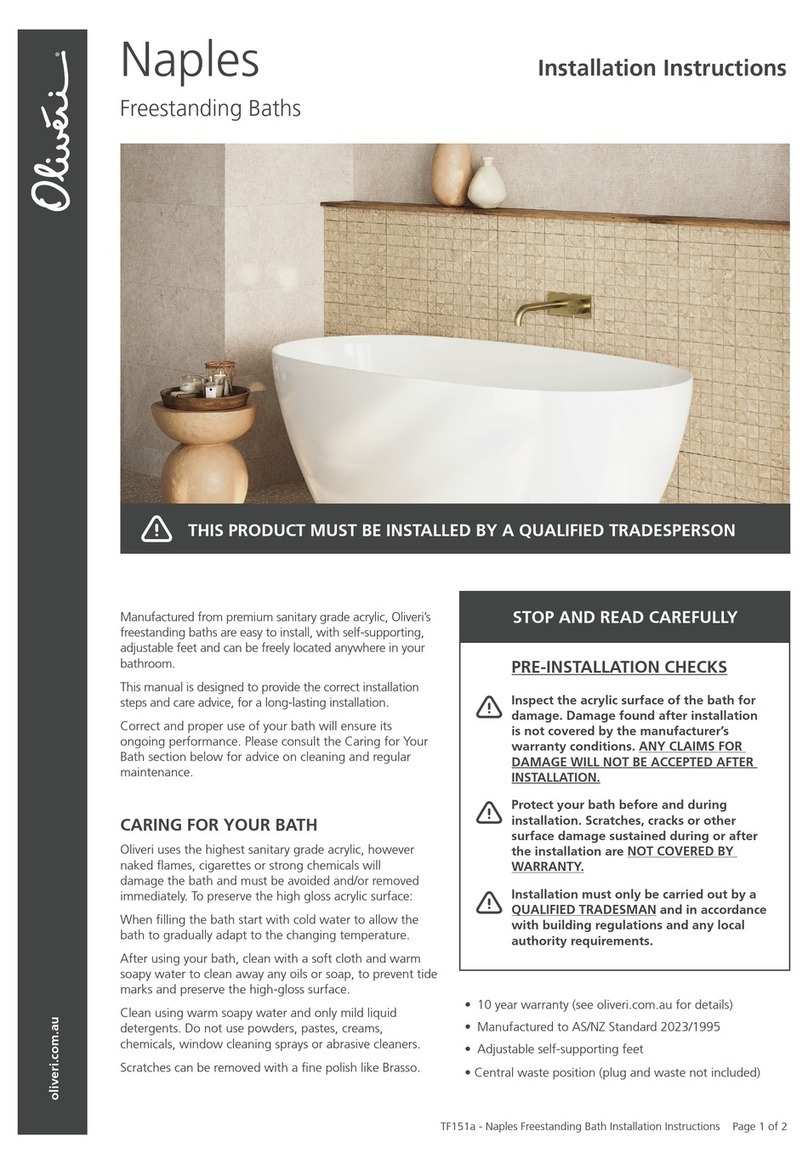

Figure 3.4.1 Tub surrounded by deck or on top of deck.

If surrounded by a deck, the deck can hide the heating

system plumbing. If on top of deck, the beauty of the tub

can be better appreciated.

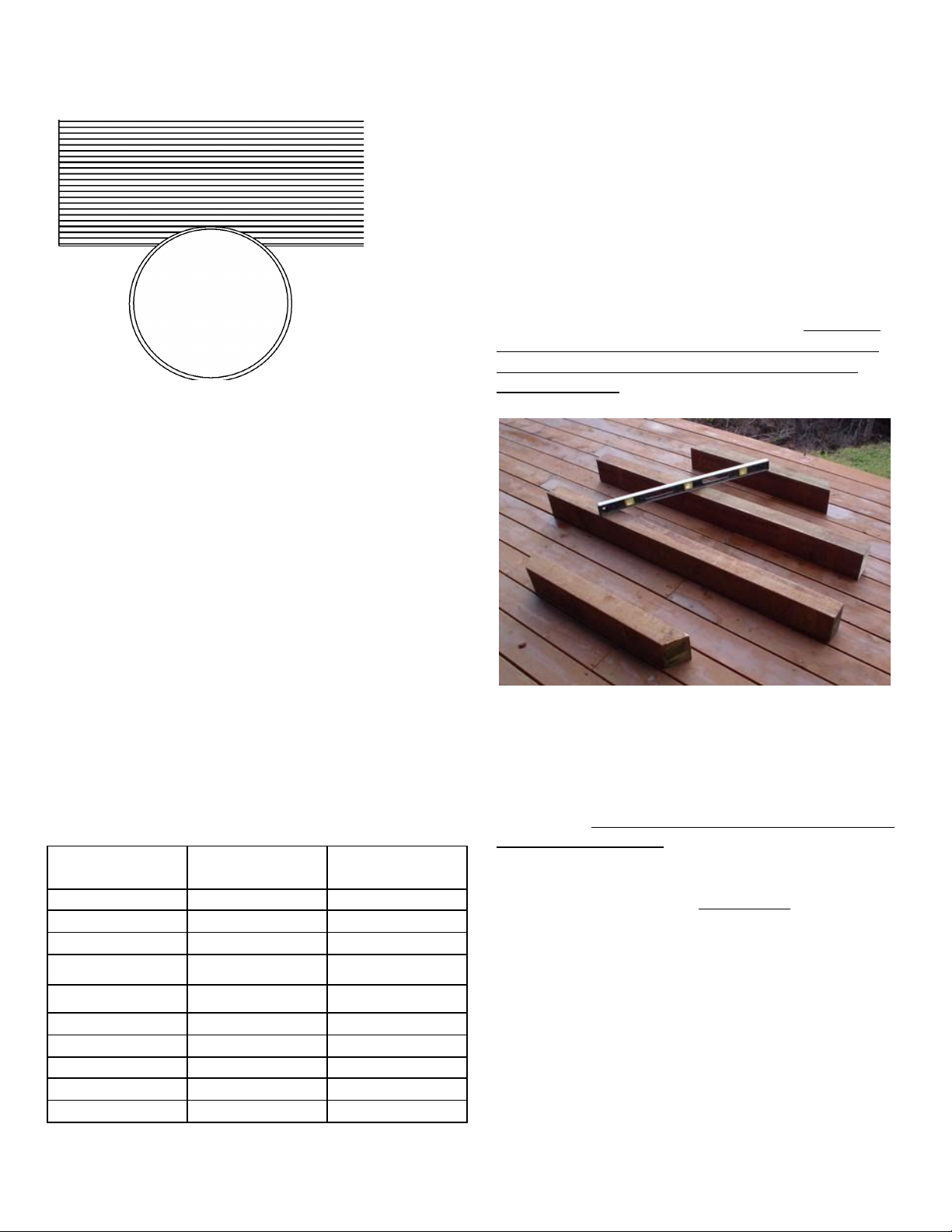

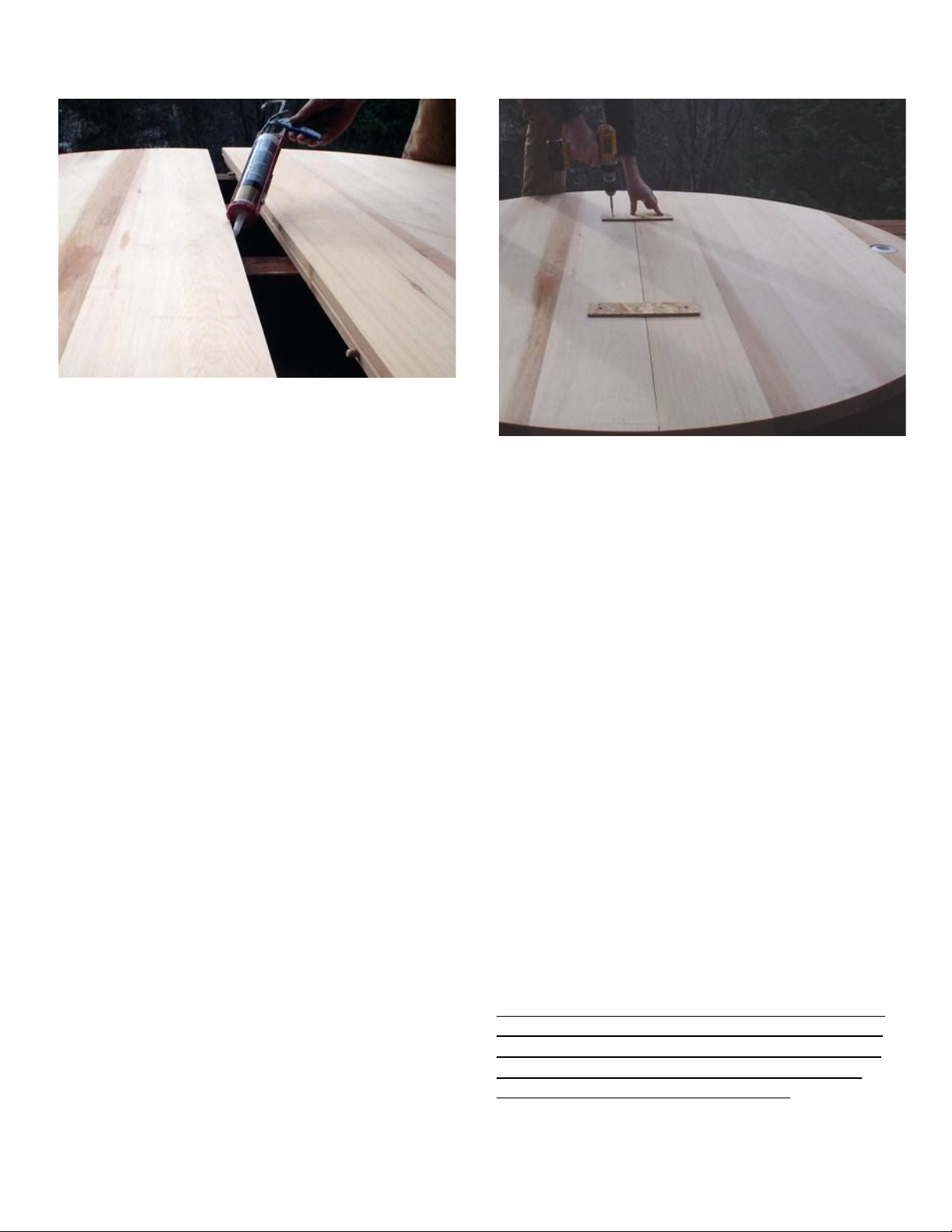

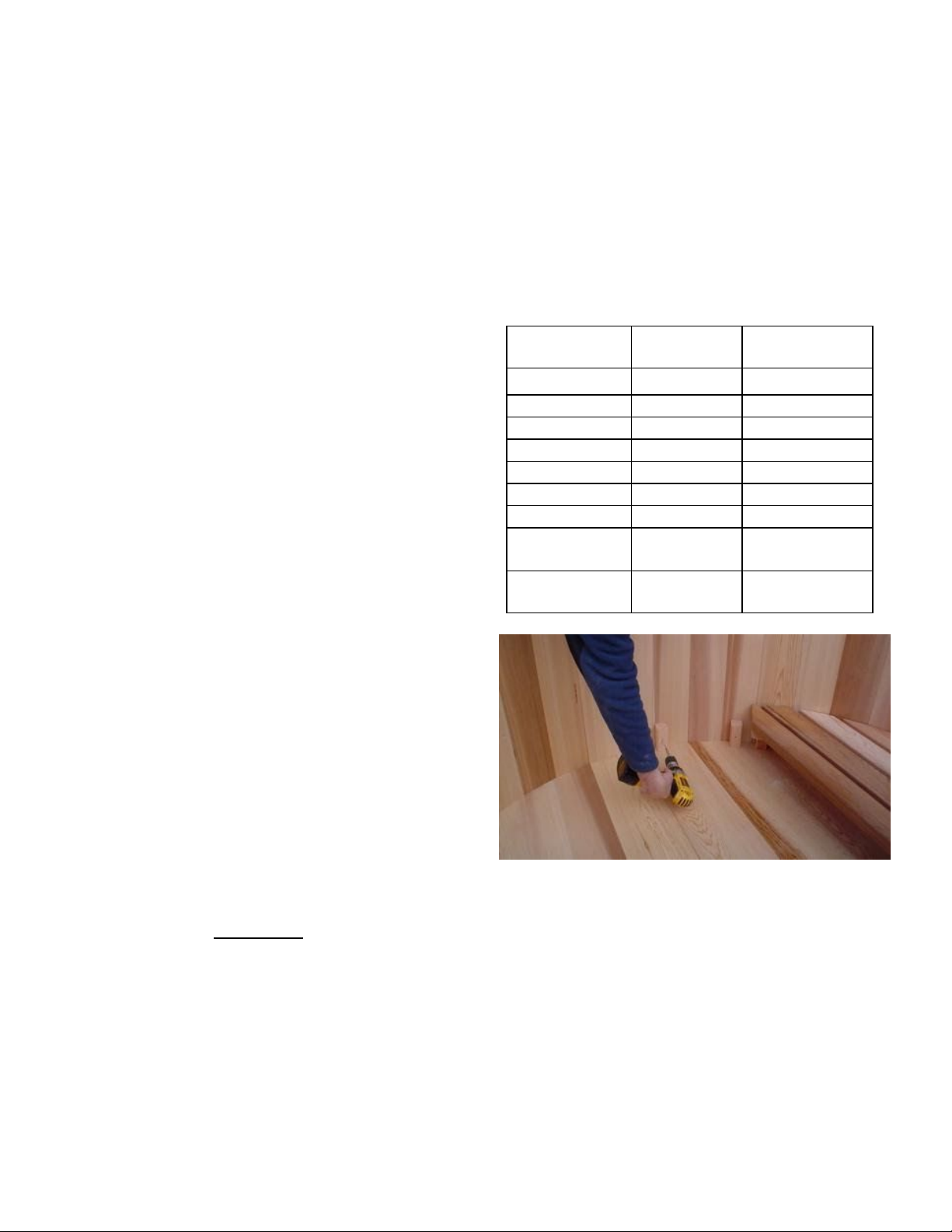

Figure 3.4.2 Tub on perimeter of deck with stairs on each

side. This arrangement allows for plumbing to be hidden

under the deck and for most of the tub to be seen. Good

choice for any heating system.