INSTRUCTION MANUAL

Rev. A

Dongguan Zerun Electronics Technolog

Co.,Ltd.

( NO.1 Xianxi Industrial Park, Zhen‘an Road, Shangjiao, Chang’an Dongguan, Guangdon, P.R. China )

2 / 9

1. Scope

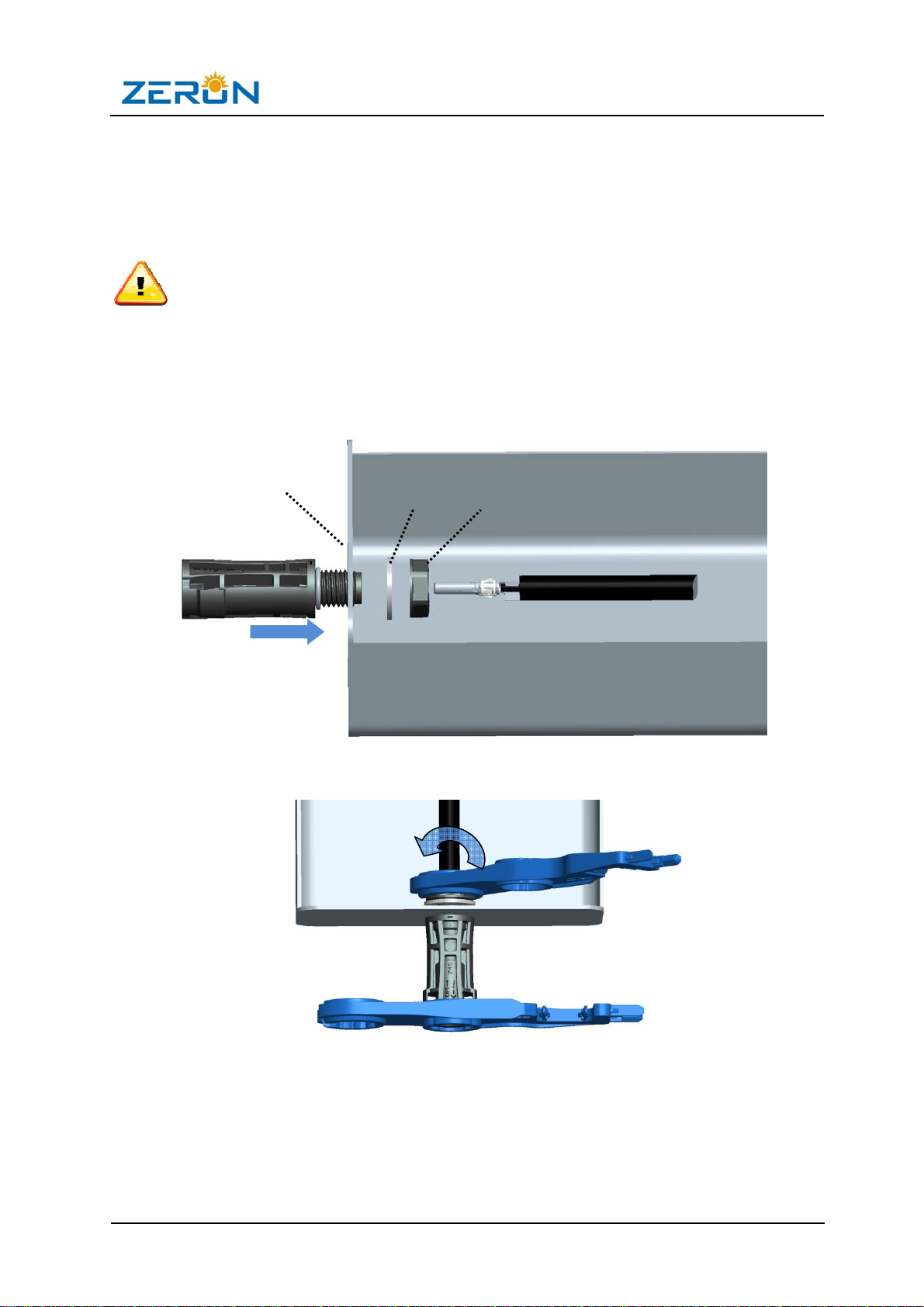

ThisManualcoverstherequirementsforapplicationoftheZ4S‐abcdeConnectoraswellasguideline

fortheassembly.

2. Product Characteristics

2.1ProductSpecifications

RatedSystemVoltage1500VDC(IEC/UL)

RatedImpulseVoltage16000V

RatedCurrent

35A(2.5mm2/14AWG)

40A(4.0mm2/12AWG)

45A(6.0mm2/10AWG)

ProtectionClassClassII

ProtectionDegree(mated/unmated)IP68(1m,1h)/IP2X

OperatingTemperature‐40℃~+85℃

2.2Features

zContactwithdrumtypecrownspring,makeelectricalconnectionfastness.

zRatchetmechanismtolockthenutcover,reliablyavoidbeingloosenedafterlongtermuse.

zSelf‐lockingbetweenthemaleandfemaleconnector,insertconvenientlyandreliably.

zStrongageingresistance,UVresistance,suitforusinginoutdoorsevereenvironment.

zCompatiblewithMC4typeconnectors(MC4,H4,PV4,etc.),TUV&ULcertificated.

zContactresistancelessthan0.30mΩ,lessheatingandlowpowerconsume.

2.3ProductFamily

Type Designation Z4S-abcde

a, b, c, d,e are variables

a: Type C: Cable mounting

P: Panel mounting

b: Releasing Method T: Tool is required

H: By hand

c: Rated Current 3: 35A (2.5mm2, 14AWG)

4: 40A (4.0mm2, 12AWG )

5: 45A (6.0mm2, 10AWG)

d: Cable Certificate

A: TUV 1000V

B: TUV 1500V

C: TUV&UL 1000V

D: TUV&UL 1500V

e: Housing Material 1: PA

2: PPE