Low Voltage Servo Drive Manuals

www.zgcmotors.com/

Notice before using

●The power supply voltage used by the low voltage servo driver is 20-90v dc.

Please install 20-90v DC power supply for the servo system. The specific voltage depends on the model.

It is strictly forbidden to connect the servo motor directly to the power grid.

●It is forbidden to connect the servo motor directly to the power grid, which is easy to damage the servo

motor. The servo motor cannot rotate without the support of the servo driver.

●Do not plug in or pull out the connector on the driver after power on. It is easy to damage the internal circuit

of the driver and the motor encoder by inserting or pulling the connector when it is charged eletricity.

●Please plug or pull the connector after the power is cut off.

Check the servo system after power off.

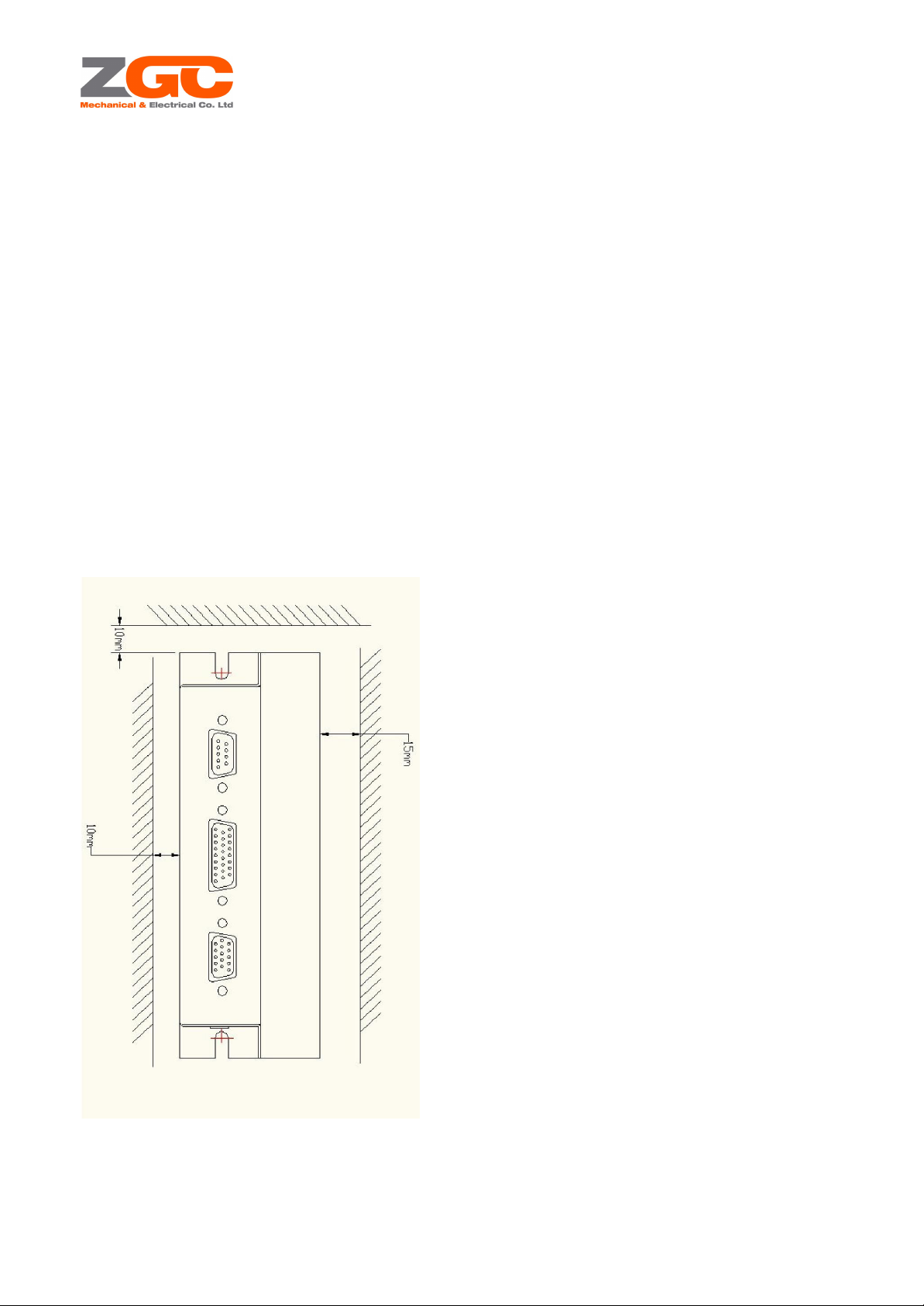

The installation interval between the servo driver and other equipment in the cabinet should be kept at more

than 10 mm.

The servo driver is easy to heat, so the installation layout that is near to heat source should be selected as

far as possible. The horizontal spacing between the servo driver and other equipment in the electric cabinet

should be more than 10 mm, and the longitudinal spacing should be more than 50 mm. The installation

environment should not be affected by condensation, vibration and impact.

Anti interference processing and grounding.

The interference on the signal line is easy to cause mechanical vibration and abnormal operation. The

following regulations must be strictly observed:

1. Separate the strong current cable and weak current cable.

2. Shorten the cable length as much as possible.

3. The installation of servo motor and driver shall adopt single point grounding, and the grounding

impedance shall be less than 10 Ω.

4. It is forbidden to use power input interference filter between servo motor and driver.

Leakage protector, quick response leakage protector should be used.

Use the quick response leakage protector or the PWM inverter specified by the supplier for leakage

protection. It is strictly forbidden to use the delay leakage protector.

Avoid extreme adjustments or changes.

It is not suitable to adjust or change the parameters of the servo driver, otherwise it is easy to cause severe

mechanical vibration and unnecessary property loss.

Do not use the power on / off to run the servo motor directly.

Frequent on / off of the power supply will lead to the rapid aging of the internal components of the servo

driver and reduce the service life of the driver. The command signal should be used to control the operation

of the servo motor.