Page 7

ENGLISH

Zodiac FloPro™E3 3-Speed Variable Pump |Installation & Operation Manual

Section 4. Operation

4.1 Start-up

CAUTION

Never run the pump without water. Running the

pump “dry” for any length of time can cause severe

damage to both the pump and motor and will void

the warranty.

If this is a new pool installation, make sure all piping

is clear of construction debris and has been properly

pressure tested. The lter should be checked for

proper installation, verifying that all connections and

clamps are secure according to the manufacturer’s

recommendations.

WARNING

To avoid risk of property damage, severe personal

injury or death, verify that all power is turned off

before starting this procedure.

1. Release all pressure from the system and open

the lter pressure release valve.

2. Depending on the location of the pump, do

one of the following:

- If the pump is located below the water level of

the pool, open the lter pressure release valve

to prime the pump with water.

- If the pump is located above the water level

of the pool, remove the lid and ll the basket

with water before starting the pump.

3. Prior to replacing the lid, check for debris

around the lid o-ring seat. Debris around the

lid o-ring seat will cause air to leak into the

system and will make it difcult to prime the

pump.

4. Hand-tighten the lid to make an air tight seal.

Do not use any tools to tighten the lid: hand-

tighten only. Make sure all valves are open

and the unions are tight.

5. Restore power to the pump.

6. Once all the air has left the lter, close the

pressure release valve.

7. The pump should prime. The time it takes

to prime will depend on the elevation and

length of pipe used on the suction supply

pipe. See Section 3.1.3.3, Installation

Recommendations, for proper elevation and

pipe size.

8. If the pump does not prime and all the

instructions to this point have been followed,

check for a suction leak. If there is no leak,

repeat Steps 2 through 7.

9. For technical assistance, call Zodiac Technical

Support at 1.800.688.152.

4.2 Operational Controls

IMPORTANT

Due to an undervoltage protection placed in the

software to protect the internal electronics, there

may be an error during motor startup. If this

situation occurs, simply let the motor sit without

power for approximately 3-5 minutes to allow the

capacitors to completely drain before restarting the

motor.

NOTE

- If power is removed, motor will return to the last

speed selected when power is restored.

- Motor will remember ON/OFF states.

- If there is a fault, Error LED will blink. See Section

6 more information on fault codes.

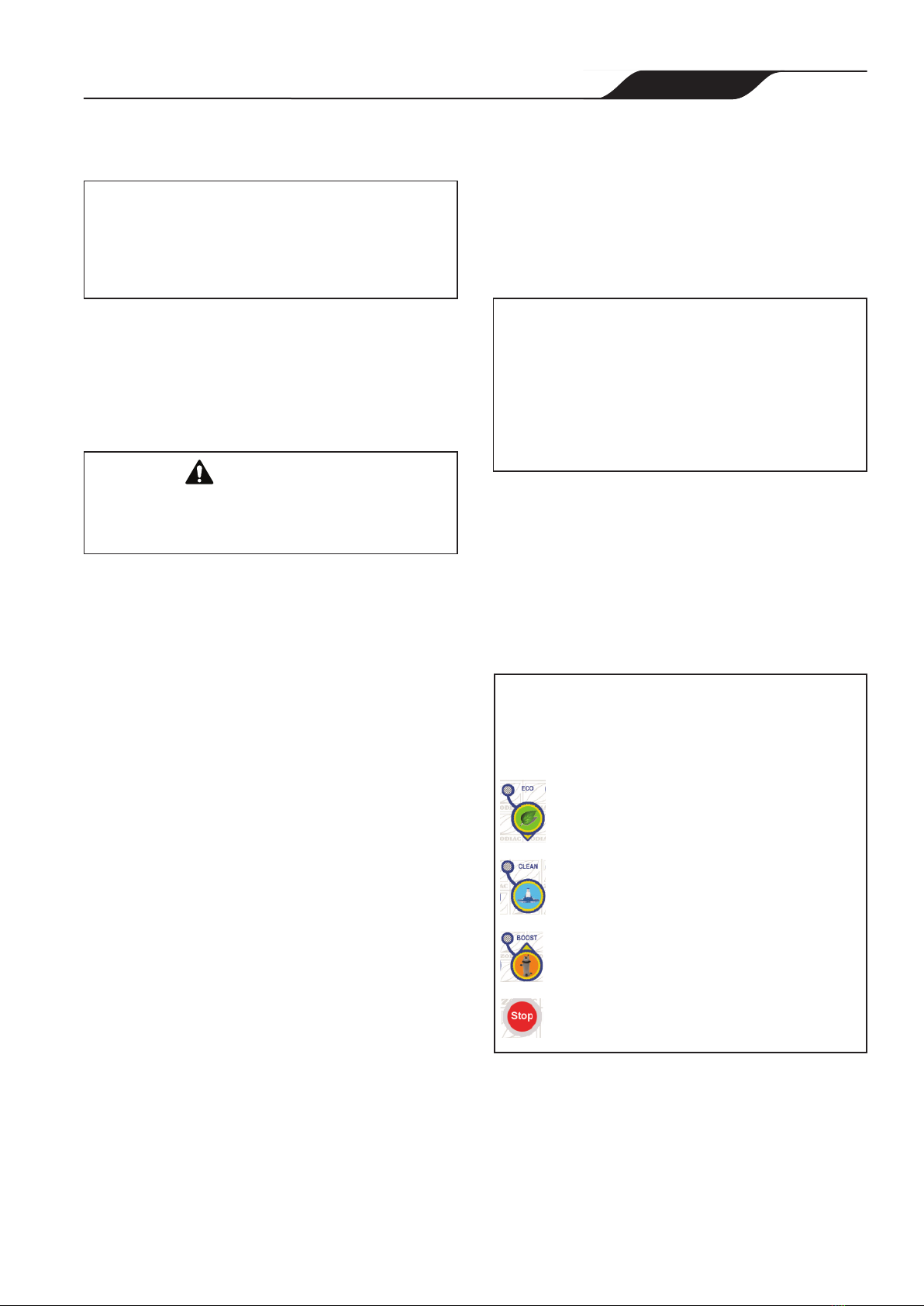

Normal Operation Mode

- For LOW speed, the LED will flash when selected

until the priming cycle is complete. Once complete,

the LED will be steadily lit.

- For MEDIUM speed, , the LED will flash when selected

until the priming cycle is complete. Once complete,

the LED will be steadily lit.

- For HIGH speed, , the LED will flash when selected

until the priming cycle is complete. Once complete,

the LED will be steadily lit.

- To turn OFF (LED will flash when selected)

On start up, the LED for the selected speed will flash for

approximately 1 minute as the pump goes through a priming

cycle. When the cycle is complete, the LED for the selected

speed will be steadily lit.

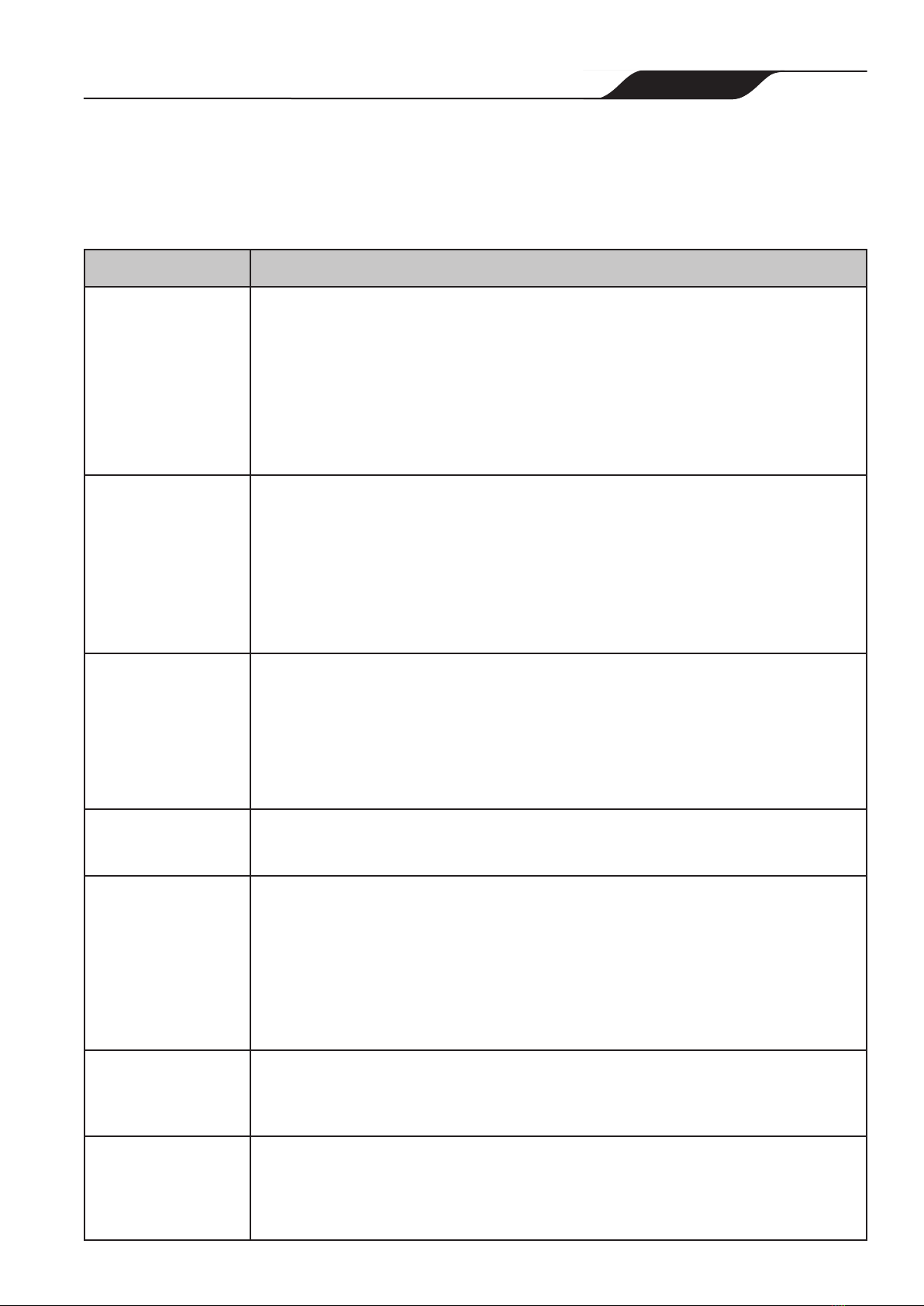

Figure 3. Normal Operation Mode Controls