www.kraftool.hk

Band Saw | 9

For performing the above, refer to the ASSEMBLY

section.

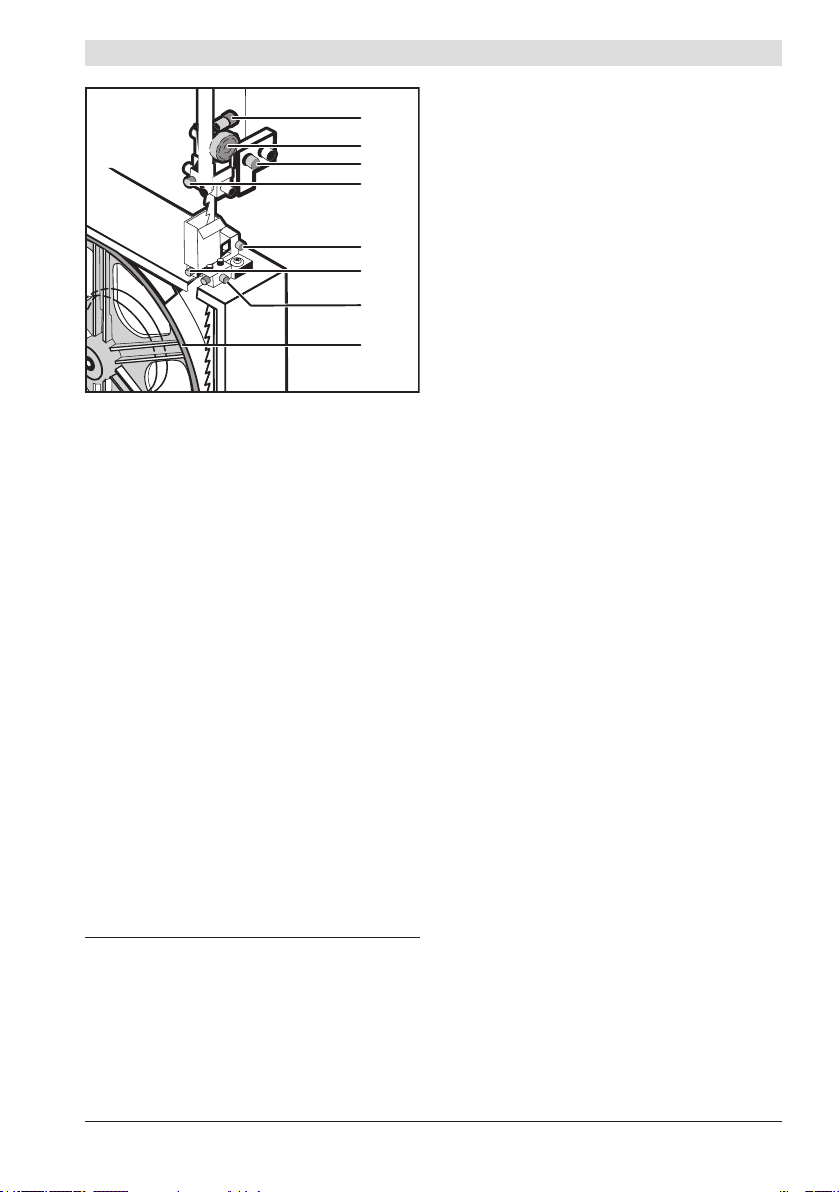

d) Adjusting of the angle pointer of the table:

`turn off the product and unplug it out of the

power;

`loosen the table tilt angle lock by releasing of

handle 11;

`using a setsquare (not included), set the right

angle between the plane of the blade and the

surface of the table;

`check a position of a bracket pointer 8. If the

position is not zero, release the pointer xing

screw, adjust its position, tighten the screw.

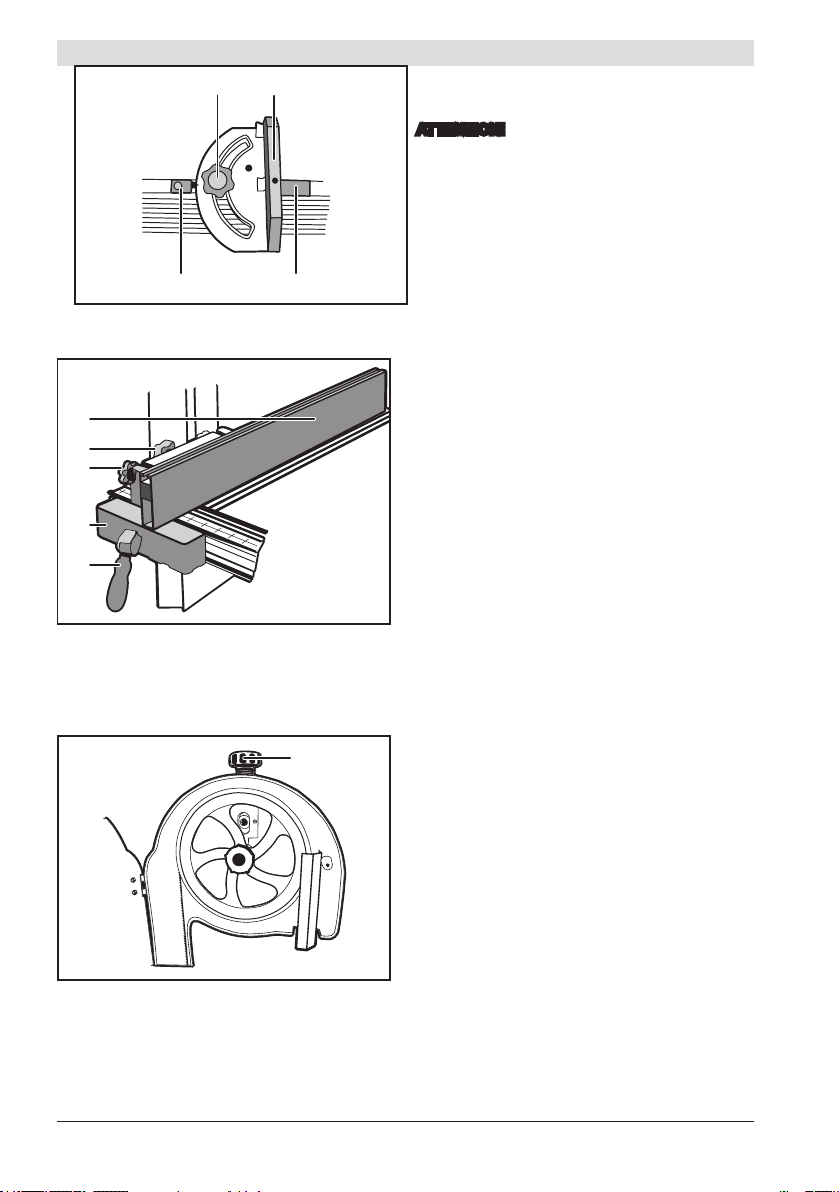

e) Adjusting of the longitudinal guide rail:

`using a setsquare (not included), check the

angle between the plane of the guide and the

edge of the table. If the angle is not a right angle,

release the two screws at the top of the plane of

the guide and adjust the angle of the guide.

`tighten the screws.

f) Adjusting of the angle detent pointer:

`loosen the xing screw of the detent;

`with the help of a setsquare, set the right angle

between the plane of the detent and the guide

groove;

`check whether protractor’s index is 90° or not. If

not, release the xing screw of the pointer - adjust

its position - tighten the screw.

g) Cleaning of the coating of driving wheels. To

clean the coating from dirt, use a hard-wearing

brush. DO NOT use solvents or other chemicals for

cleaning.

Operating Instructions

Make sure that the voltage of your power supply

corresponds to the rated voltage of the product.

Connect the product to the power when you are

ready to work only.

Before using the product for the rst time, turn it on

without any load and let it run for 10-20 seconds. If at

this time you hear a strange noise, feel an increased

vibration or the smell of burning, turn off the product,

disconnect the power cord from the power and nd

out the cause of this phenomenon. Do not operate

the product before the cause of the malfunction is

found and rectied.

Provide good lighting, ventilation (or connect a

vacuum cleaner to the product - dust is generated

in large quantities during the sawing process) and

workplace order - insufcient lighting and foreign

objects can lead to damage and injuries.

To avoid accidents, each time before turning on the

product, make sure that:

`the saw blade is correctly installed and tensed;

`wheels and limiters are adjusted;

`You removed all hand tools and foreign objects out of

the rotating parts of the product and out of the work area;

`there are no metal objects (nails, screws, etc.) in

the workpiece.

For electrical safety, the product corresponds to the

1st class of protection against electric shock, i.e. it

must be grounded (grounding contacts are provided

for this purpose). Do not modify the plug yourself if

it does not t into your socket. Instead, a qualied

electrician must install a suitable plug.

The product is designed ONLY for sawing wood

products and derived materials (plywood, chipboard,

berboard, MDF), as well as laminated panels and

various types of plastic.

DO NOT cut other materials (metal, ceramics, stone),

and also do not install a different interchangeable tool

(of other types, with dimensions different from those

indicated in the characteristics, damaged - with worn

teeth, cracks, twisted).

For your work we recommend to use a replaceable

tool of the «3Y6P» brand.

To avoid injury, do not place your hands in the

sawing area.

DO NOT saw the workpieces (especially long ones,

with uneven surfaces), just holding them with your

hands. ALWAYS use the longitudinal guide rail.

Always FIRMLY hold the workpiece.

DO NOT ever saw:

`rounded workpieces;

`workpieces that are so small that you can not

hold them;

`several workpieces simultaneously.