FV613 Rev. A 4/27/2018

Page 2

Overview:

Designed for modern commercial restrooms, the Sundara system delivers a superior user experience in both form and func-

tion. Crafted by world-class industrial designers Sundara combines seamless basin designs with curated faucets and soap

dispensers, delivering a complete, easy to install hand washing solution.

Specications:

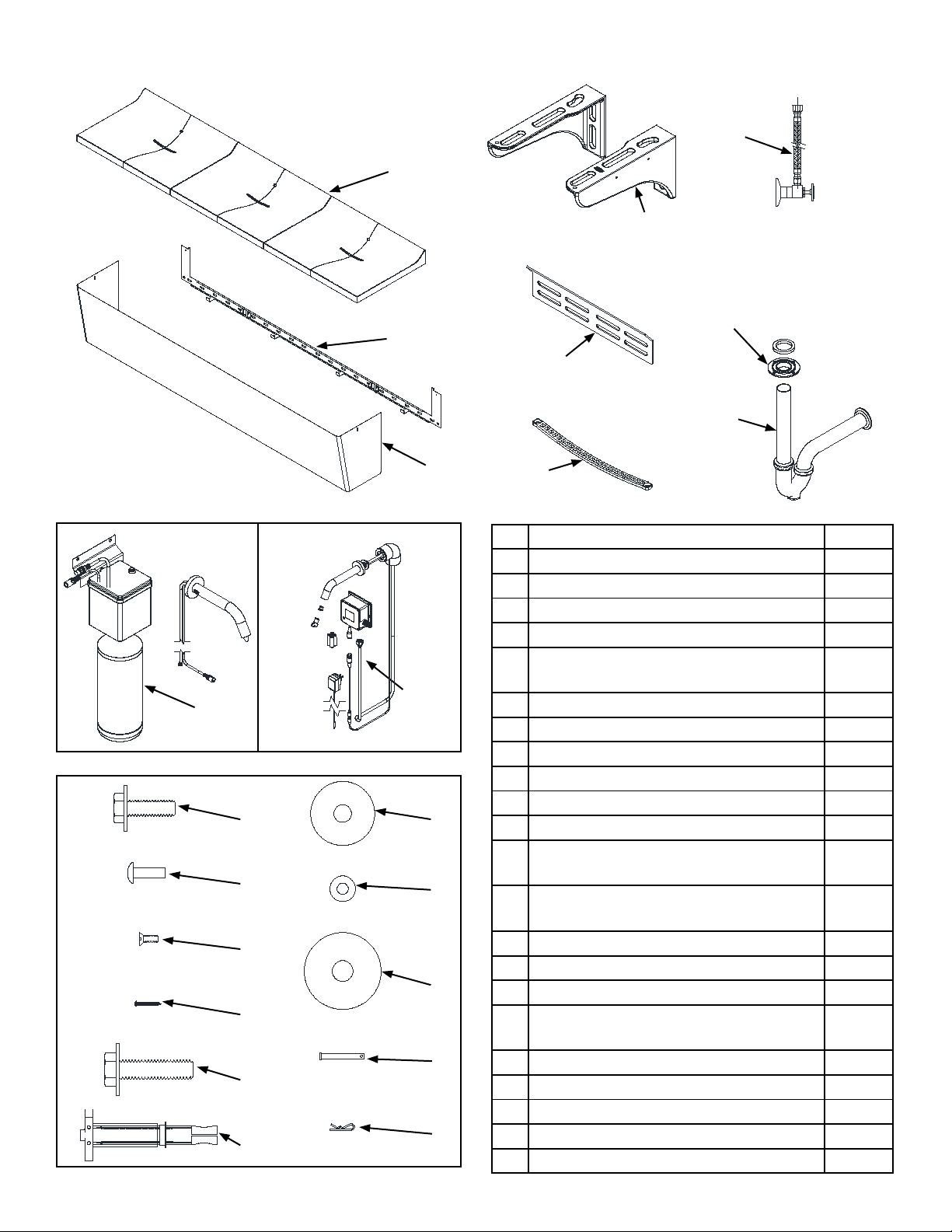

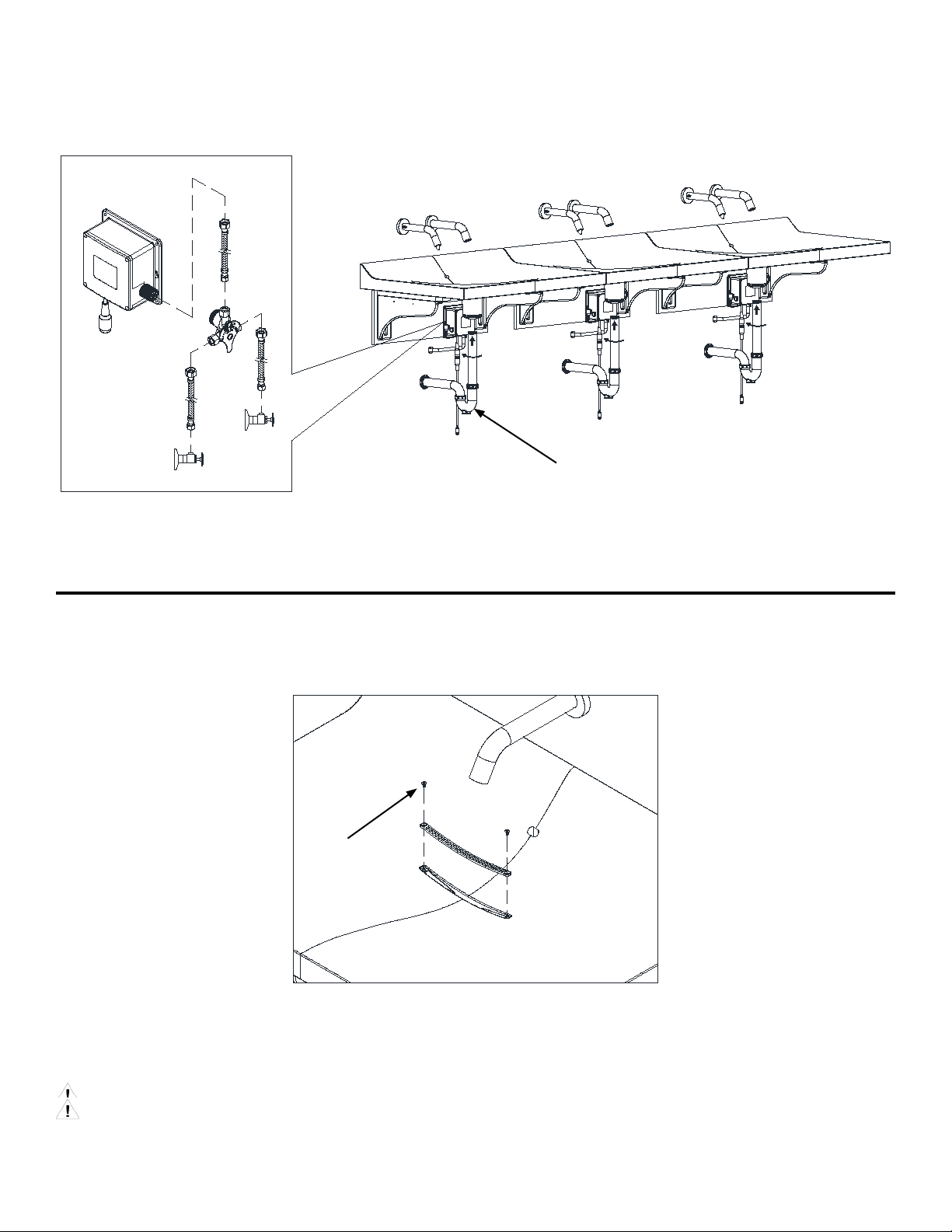

Sundara®Drift triple basin lavatory system manufactured by Zurn Industries. Lavatory shall be mounted at standard height to

conform with ANSI, UFAS, TAS and ADA Accessibility Standards. Counter and integral basin to be constructed of Sundara®

solid surface resin with aluminum trihydrate and other additives conforming to CSAB45.5/Z124 and IGC 156 standards.

Shroud enclosure is constructed of satin nished type 304, 18 gage stainless steel designed for easy access with vandal

resistant hardware. Lavatory is furnished complete with 0.5 gpm laminar ow sensor operated faucet (specify model) and

optional liquid soap dispenser (specify model), ½” quarter turn supply stops, 3/8” exible supply risers, chrome 1 ¼” tail piece,

and chrome 1 ¼” p-trap for complete system operation.

Paired Faucet Typical Specication

(Refer to faucet manual for more details on specic model)

Voltage: 6 VDC Series [4 “AA” (Alkaline or Lithium) and/or external power option]

Sensor Range: Self-calibrated, dependent upon sink depth and nish.

Operating Water Pressure: 10-125 psi

Operational Water Temperature: 33°F to 140°F (1°C to 60°C)

Aerator: 0.5 GPM Vandal-Resistant (Standard)

Paired Soap Dispenser Typical Specication

(Refer to soap dispenser manual for more details on specic model)

Power Supply: AC 110 V; DC 6V

Soap Viscosity: 100-3800 cps

Operating Temperature: 340- 1310F

Typical Dispensed Volume: 1.25 ml

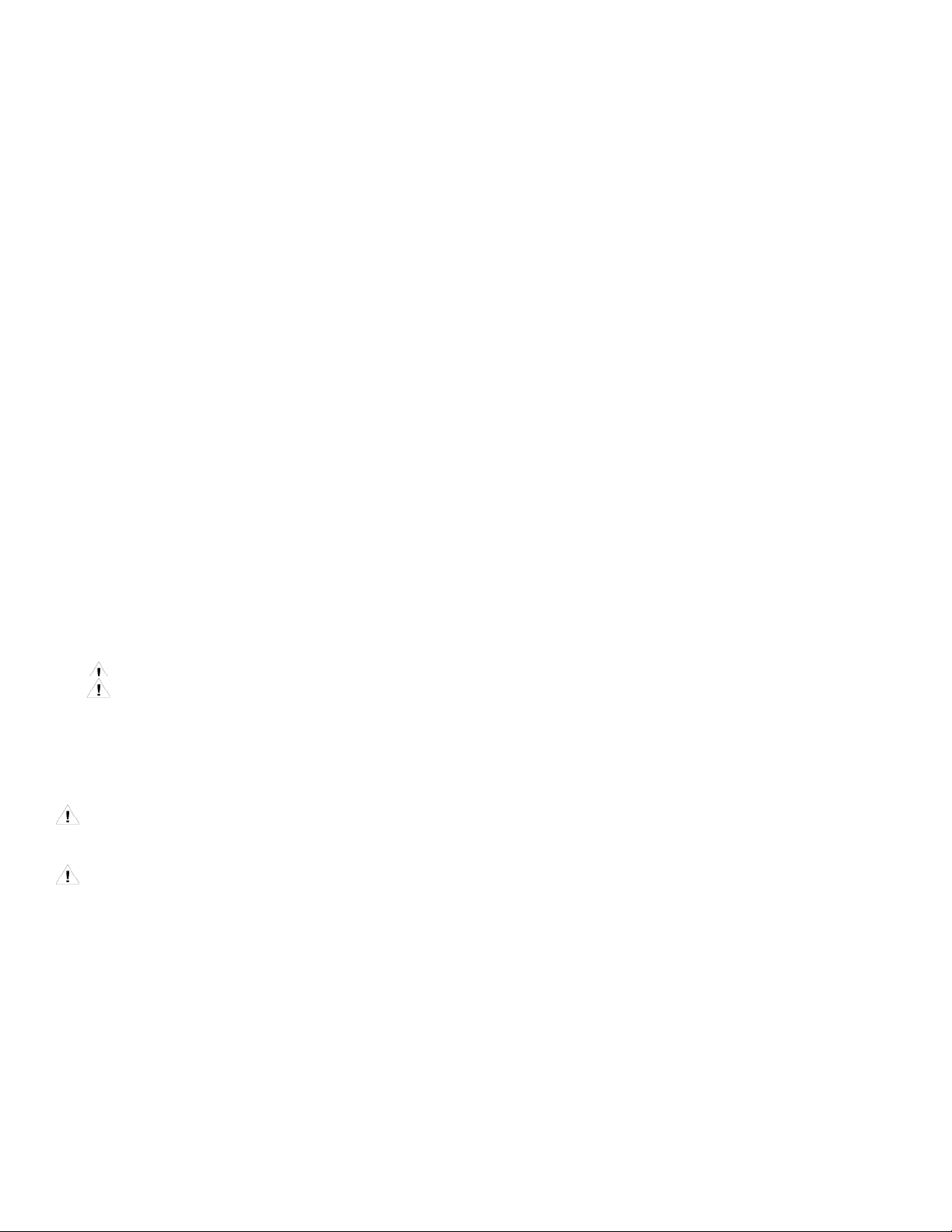

Be sure the sink/lavatory/basin is clear from any objects upon making the sensor to electronics connection initiating the self-

calibration feature. The sink must be clear of any and all objects in order to calibrate appropriately (calibration time approx 30-

60sec).

Prior to Installation:

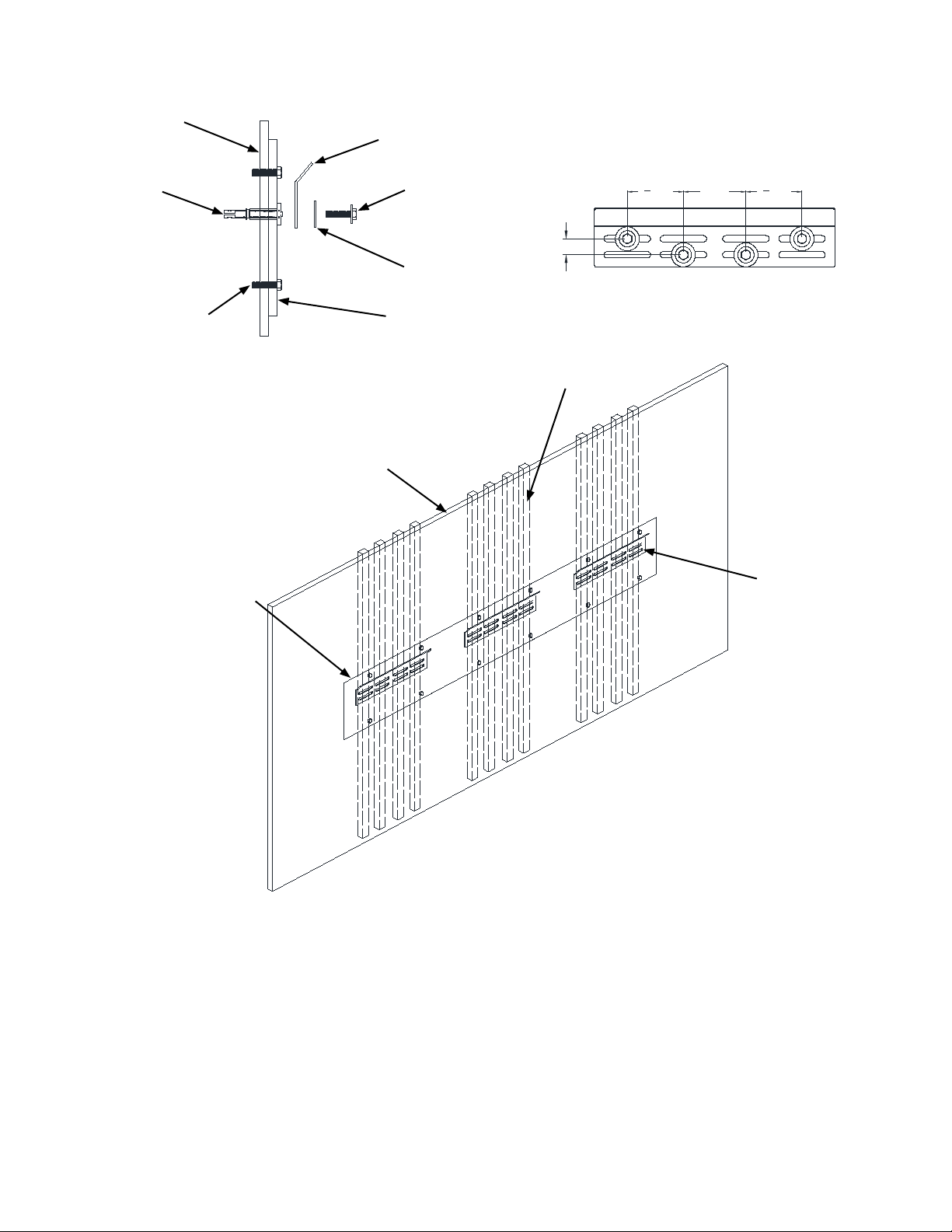

• If applicable, carrier (Z1240 series) is installed behind the wall.

• Hot and cold water supply lines are installed as per building codes.

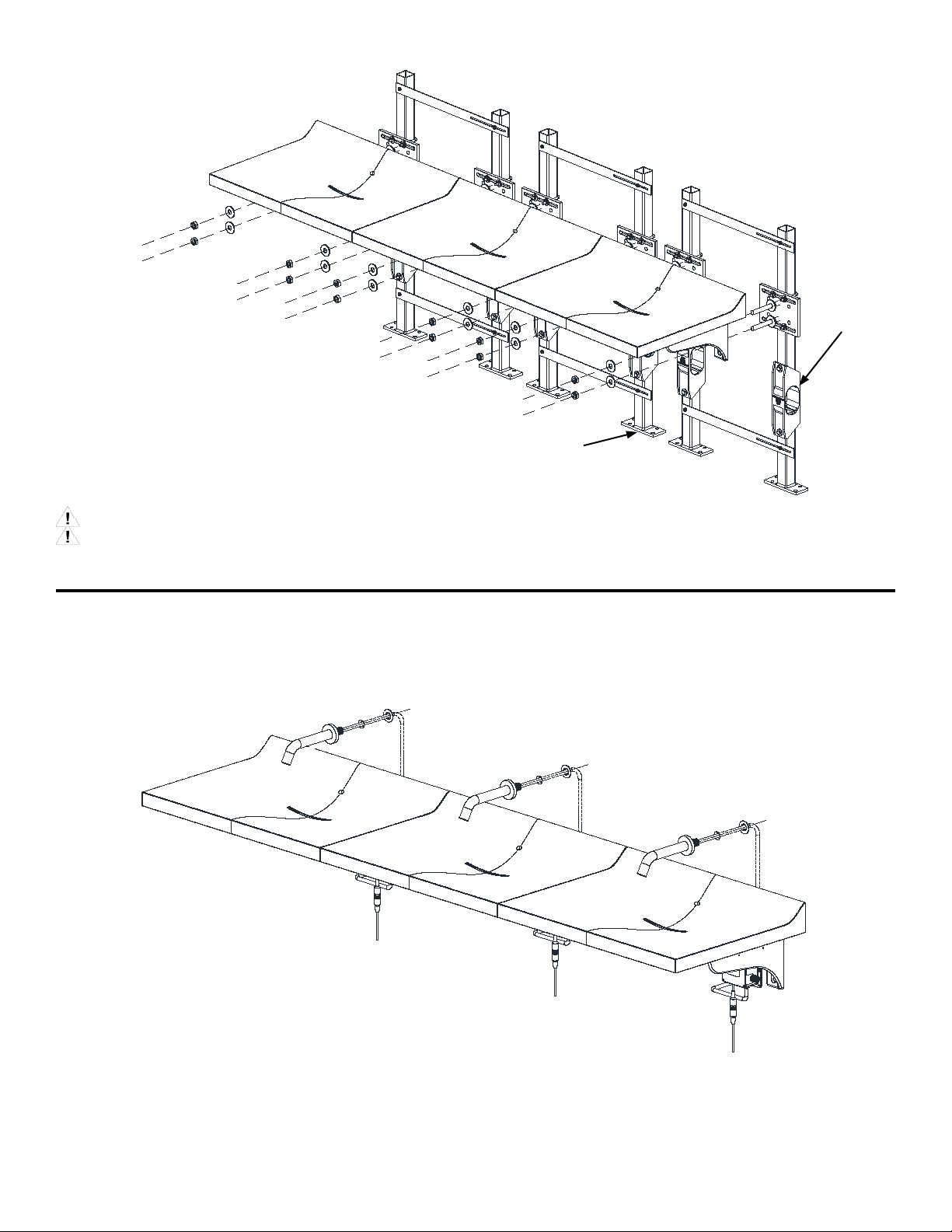

• Care shall be taken when installing this product to prevent damage of any exposed or decorative surfaces.

• Measure the drain outlet from the oor.

Important Safety Information:

• Installer is responsible for ensuring the product is installed and conforms to all plumbing codes and ordinances.

• Do not convert or modify this Zurn product yourself. All warranties will be voided.

• Water supply lines must be sized according to building design in order to provide adequate water supply for each xture.

• Flush all water lines prior to making connections.

• Minimum 2 people required for the sink installation

• Au minimum, 2 personnes sont requises pour l’installation du lavabo.

S’assurer qu’aucun objet ne se trouve sur l’évier/le lavabo/le bac lors du branchement du capteur sur l’électronique, ce qui lance la

fonction d’auto-étalonnage. Rien ne doit se trouver sur le lavabo pour permettre son auto-étalonnage correct (temps

d’étalonnage de 30 à 60 s environ).