Pagina 3 ǀ8

2.1. Regulations and guidelines

Follow the relevant accident prevention regulations, environmental regulations and statutory

rules for assembly, installation and operation, as well as the relevant safety regulations of

DIN, EN, DVGW, VDE and VDI and any national standards, laws and regulations.

The electrical wiring work may only be carried out by qualified electricians. The rules as well

as the guidelines of the competent power supply company have to be kept.

The hydraulic connection work may only be carried out by qualified personnel. The valid rules

and regulations have to be kept.

2.2. Transport

The storage may only be transported upright!

For transporting you can use the hooks on the top of the tank.

At the receiving, the storage and accessories must be checked for possible

transport damage. Neither the manufacturer nor the supplier is liable for shipping

damages, but the freight carrier. After the acceptance of goods without objections

transport damages can no longer be asserted.

3. Installation

The installation, start-up, as well as maintenance and repair of the device may only

be carried out by an expert technician. A safety valve is necessary at the cold water

pipe. The device has to be run with pressure fittings.

3.1. Site

Be sure that the floor is stable

Be sure that the floor is even

Pay attention to ceiling height and tilted dimensions (see chapter 5: “Technical Data”)

3.2. Insulation

Place the device at its location and align it according to the installation. At this pay attention

to sufficient assembly freedom. Then assemble the insulation. After assembling the insulation

you can start with the integration to the heating and hot water system.

3.3. Vent valve

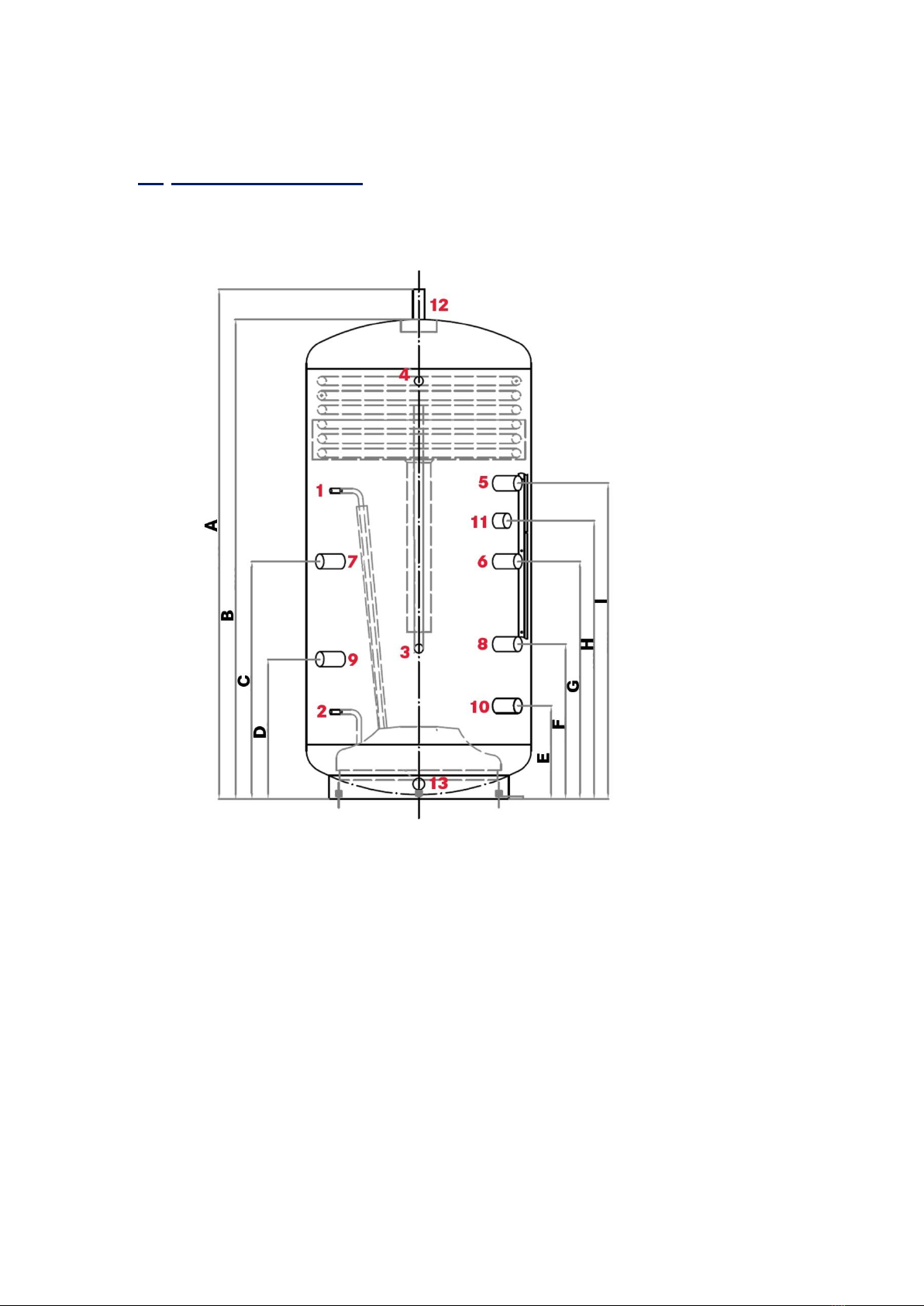

Assemble a manual vent valve at the vent nozzle (12)