Features and Functions

The design and production concept underlying all

3B6 products is refined simplicity.

This makes TOP MASTER one of the most user-

friendly, technologically advanced weighing systems.

It has been programmed with all the information

necessary for better management of your machinery.

TOP MASTER is a weighing system, which can

measure the load on moving mobile machines,

particularly, wheel loaders and lift trucks.

Its main features are:

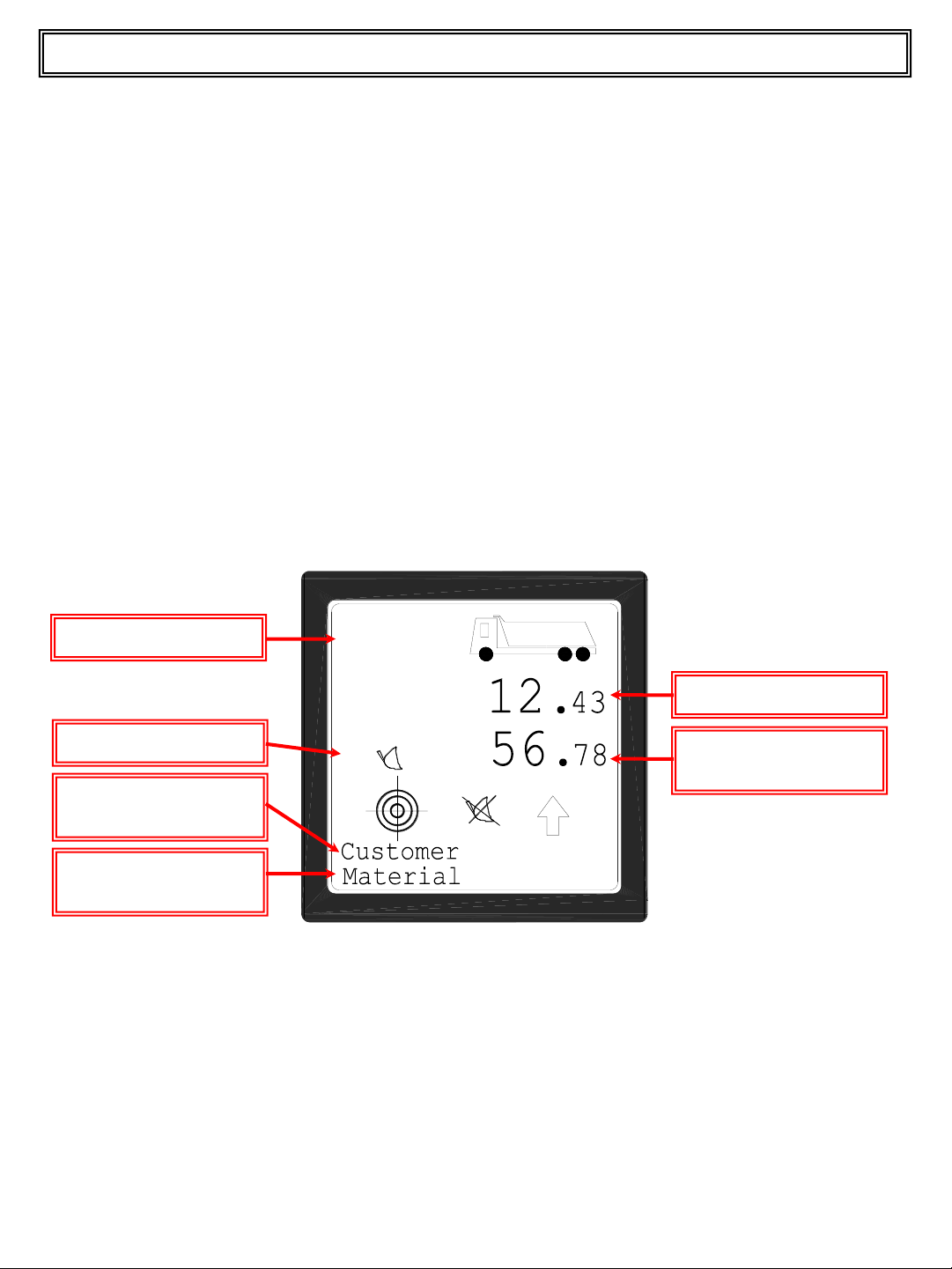

•alphanumerical display

•dynamic weighing (without stopping the lifting arm)

•display of partial weights and relative totals automatically

summed without operator intervention

•possibility of partial zeroing for precise loadings

•setting of 1000 different clients with name, address, etc.

•setting of 200 types of materials with name

•setting 50 different operators

•setting 500 truck Nos.

•setting 100 projects

•sum of the truck loads

•subtraction of the partial loads starting from the target

•display of totals for materials

•4 different calibrations

•set the maximum load

also if the system has a printer:

•print tickets for each weighing

•print total tiucket at the end of each load

•end of day (week, month or year) summary grouped together by type of material loaded.

•date and time

•Load up to 10 different materials on the same truck

•Load up to 10 different trucks in the same time.

TOP MASTER systems have RS-232/C serial communication for connections with other

intelligent external units: infrared port, modem, radio etc. and to enter further code No. from

the optional alphanumerical keypad.

3

Top Master User Manual