9

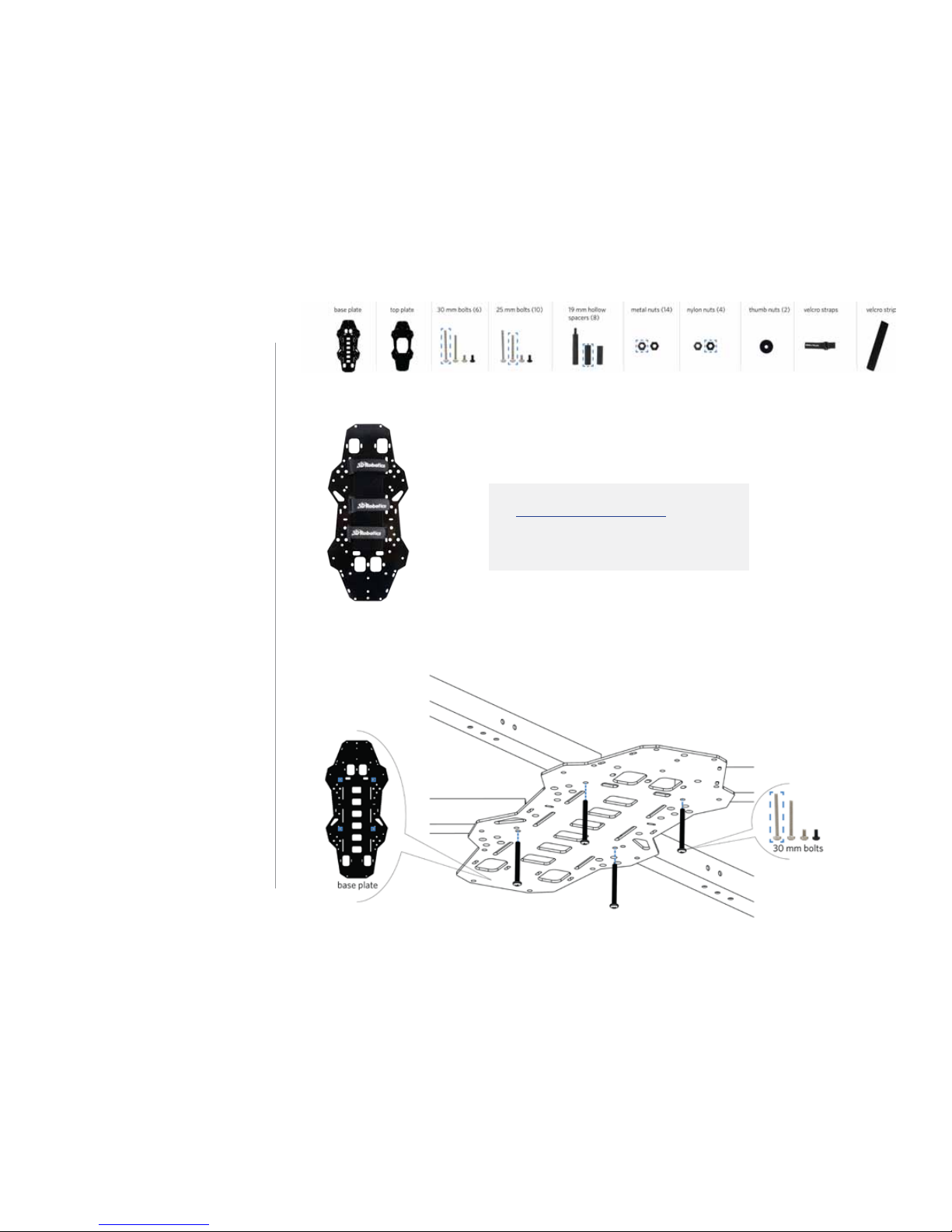

3Body plate

assembly

Follow these instructions to assemble

the body plates.

1 Add velcro straps to base plate

Thread the two velcro straps through

the slots in the base plate. These

straps will hold the battery to the

bottom of your copter. The perfectly

flat side of the plate (without the

protruding nuts) should face down.

Your kit includes two velcro strips to

attach to the battery and the bottom

of the copter. To install, attach the

strip with loops (fuzzy) to the bottom

of the plate between the straps, and

attach the strip with hooks (smooth)

to your battery.

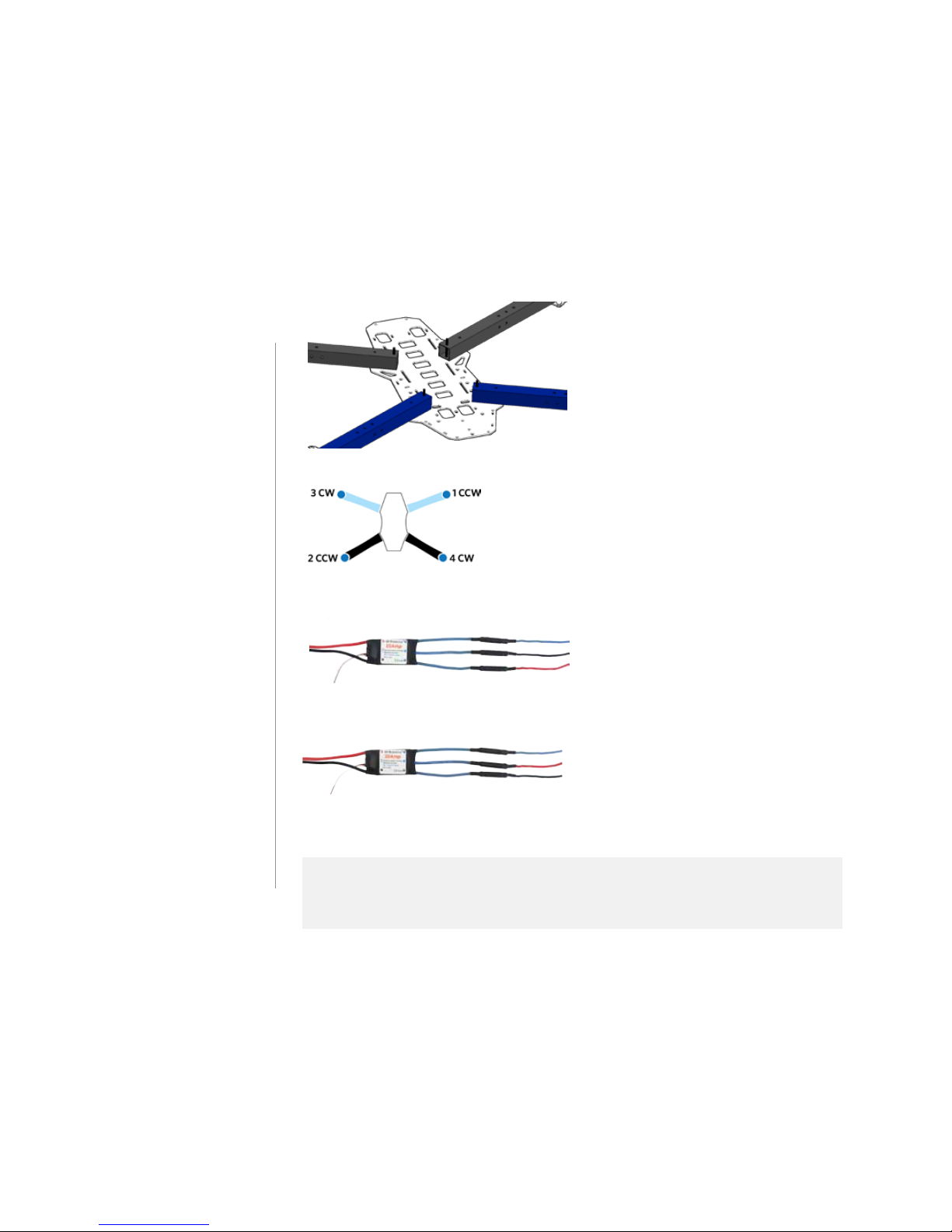

2 Attach arms to base plate

Now we’ll attach the four arms with

assembled motors to the base plate.

Using the innermost hole in the arm

and the hole in the base plate marked

below, insert a 30 mm screw from

the bottom, up through the plate and

the arm. Attach the two black arms

and two blue arms as shown in

relation to the shape of the plate.

(Attach the black arms to the more

elongated end of the plate.)

Visit the APM:Copter Wiki and learn

more about which batteries to use

with your copter.