ENGLISH 4

Dear Customer,

Thank you for choosing this quality product from our company.

1.3 About these Instructions

• These instructions are original translation of an

operating instructions, outlined in the EC Directive

2006/42/EC.

• Read through all of the instructions carefully, as they

contain important information about the product.

• Pay attention to and follow the instructions provided,

particularly the safety instructions and warnings.

• Please keep these instructions in a safe place and make

sure that they are available to all users at all times.

1.4 Further applicable documents for

customer/users

Please ensure that the following guides were ultimately

delivered to the customer who uses the product:

• this guide / instructions

• Digital control board MS1024 guide

• Hinged gate guide / instructions

1.5 Caution Indications

The general warning symbol indicates a danger

that can lead to injury or death.

In the text, the general warning symbol will be used in

connection with the caution levels described below. In the

illustrated section, an additional instruction refers back to

the explanation in the text.

DANGER!

Indicates a danger that leads directly to death or

serious injuries.WARNING!

Indicates a danger that can lead to death or serious

injuries. CAUTION!

Indicates a danger that can lead to minor or moderate

injuries. ATTENTION!

Indicates a danger that can lead to damage or

destruction of the product.

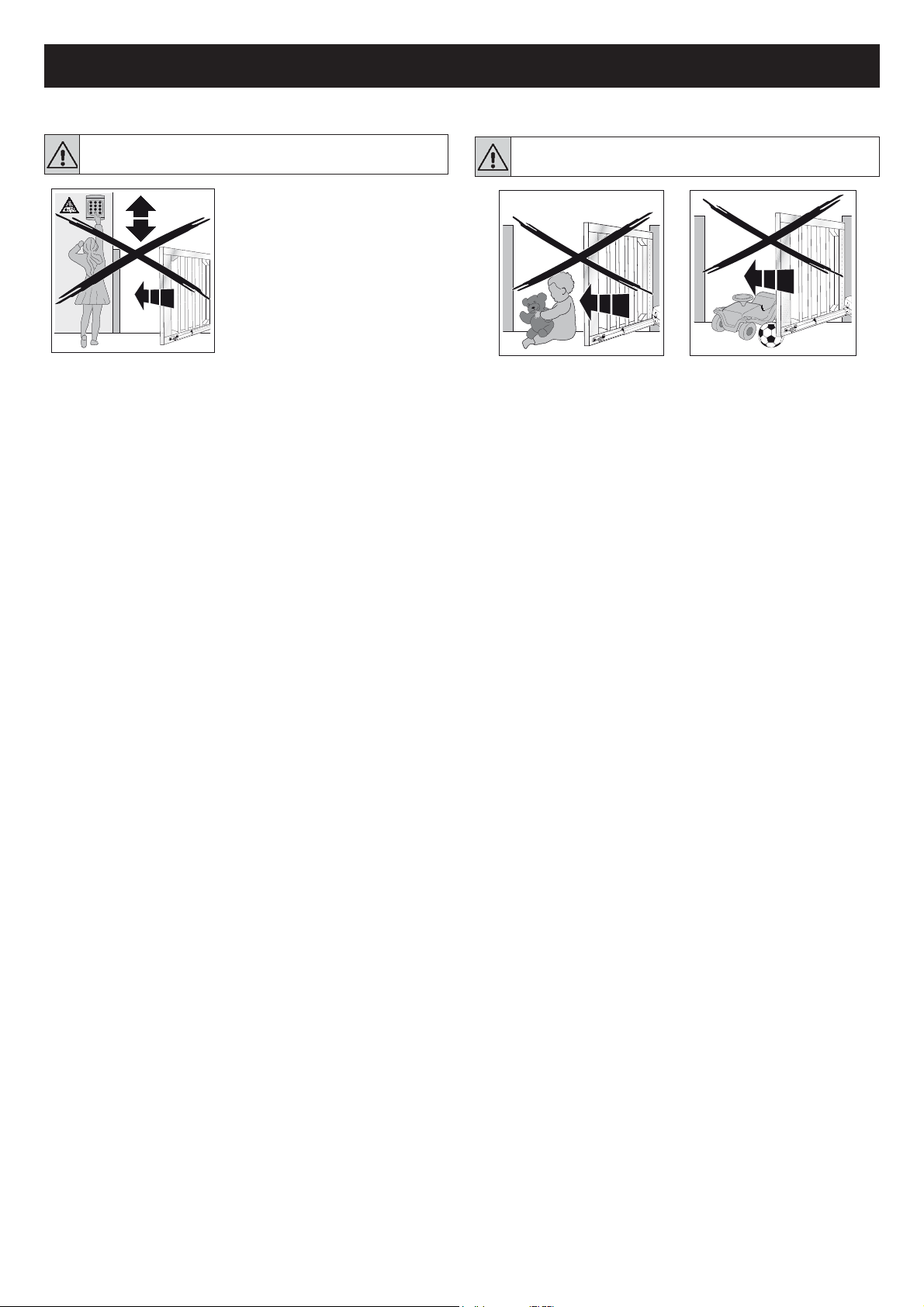

2 SAFETY PRECAUTIONS

2.1 Intended use

The hinged gate operator is designed and intended

exclusively for the operation of smooth-running hinged

gates in the domestic and commercial sector.

The maximum permissible gate size and maximum weight

must not be exceeded.

The gate must be easy to open and close by hand.

Please observe the manufacturer‘s specifications

regarding the door and operator combination.

Possible hazards as defined in EN 12604, EN 12445

and EN 12453 are prevented by the design itself and

by carrying out installation in accordance with our

guidelines. Gate systems used by the general public and

equipped with a single protective device, e.g. force limit,

may only be used when monitored.

2.2 Inappropriate use

The gate-operator is not designed for use with larger

heavy-weight or sluggish gates or gates with an

ascending slope.

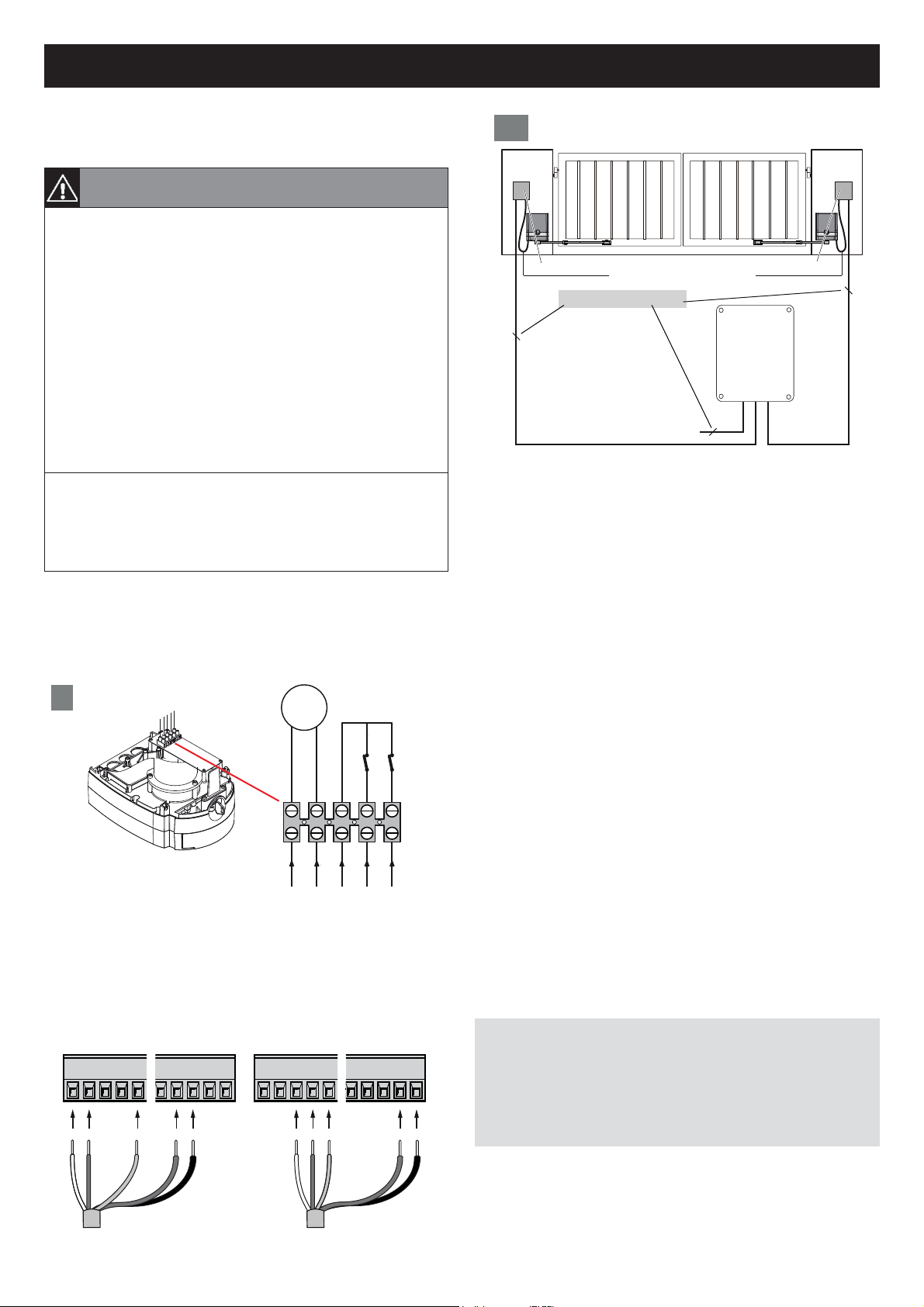

2.3 Fitter qualification

Only correct fitting and maintenance in compliance with

the instructions by a competent/specialist company or a

competent/qualified person ensures safe and flawless

operation of the system. According to EN 12635, a

specialist is a person with suitable training, specialist

knowledge and practical experience sufficient to

correctly and safely fit, test, and maintain a gate system.

Work to be carried out (mounting, maintenance, repair

and dismantling) by qualified service personal only!

Should the hinged gate operator fail, a specialist must

be immediately entrusted with its inspection / repair.

2.4 Important instructions for a safe

installation

Any further processing must ensure that the national

regulations governing the operation of electrical

equipment are complied with.

2.4.1. After installation

The installer of the gate system must declare conformity

to DIN EN 13241-1 in accordance with the scope of

application.

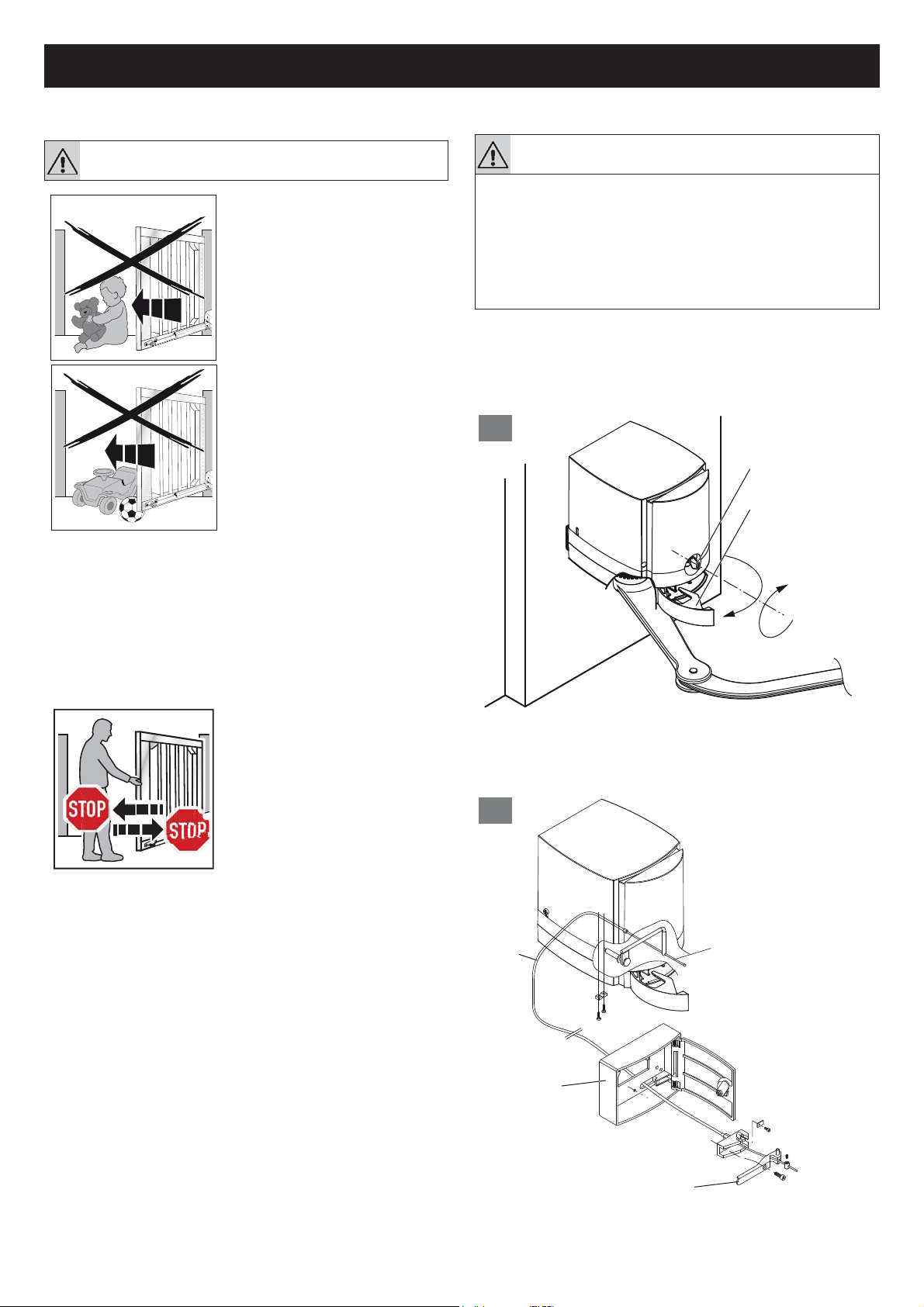

2.5 Checking the gate / gate system

The design of the operator is not suitable nor intended

for the opening and closing of heavy gates, i.e. gates

that can no longer be opened or closed manually. Before

installing the operator, it is therefore necessary to check

the gate and make sure that it can also be easily moved

by hand.

In addition, check the entire gate system (gate pivots,

bearings and fastenings) for wear and possible damage.

Check for signs of corrosion or fractures. The gate

system may not be used if repair or adjustment work

needs to be carried out. Always remember that a fault

in the gate system or a misaligned gate can also cause

severe injury.

Note

Before installing the operator and in the interests of

personal safety, make sure that any necessary repairs

to the gate are carried out by a qualified service

engineer.