VZN V SERIES

2P/N 1011079 Rev. J 01/14

OWNER INFORMATION

TABLE OF CONTENTS

IMPORTANT! Keep these instructions for future reference. If the system changes

ownership, be sure this manual accompanies the equipment.

Owner Information ...............................................................2

General............................................................................... 2

Warranty Information.......................................................... 2

Service/Technical Assistance ............................................. 3

Important Safety Information ..............................................4

Specifications .......................................................................6

Dimensions......................................................................... 6

Electrical Ratings ............................................................... 6

Replacement Cartridges .................................................... 6

Electrical Cord & Plug Configurations................................ 6

Performance Data Sheet......................................................7

Filter Cartridge Capacities.................................................. 7

Performance Claims for Percent Reduction....................... 7

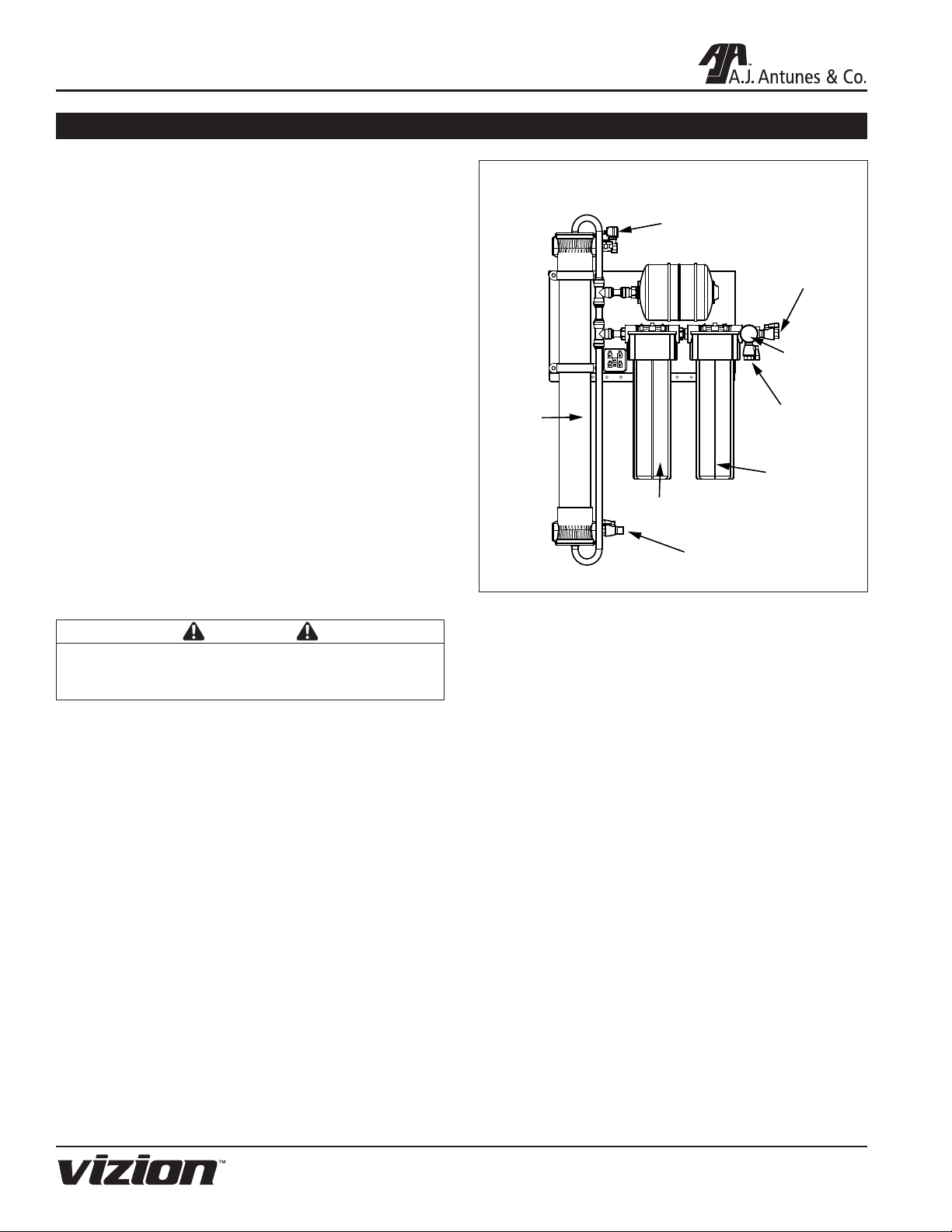

Operation...............................................................................8

Overview ............................................................................ 8

Manual Flushing................................................................. 8

Installation.............................................................................9

Unpacking .......................................................................... 9

Equipment Setup................................................................ 9

Mounting the System ....................................................... 10

Drain Valve Connection.....................................................11

Rinse Valve Connection ................................................... 12

System Inlet Connection .................................................. 12

Filtered Water Permeate Outlet Connection .................... 12

Inlet Water Plumbing........................................................ 12

Installing a Bypass ........................................................... 13

Starting the Controller ...................................................... 13

Rinsing the Ultra Filter Cartridge...................................... 13

Sanitizing the System and Lines...................................... 14

Rinsing the Carbon Element and TAC Cartridge ............. 14

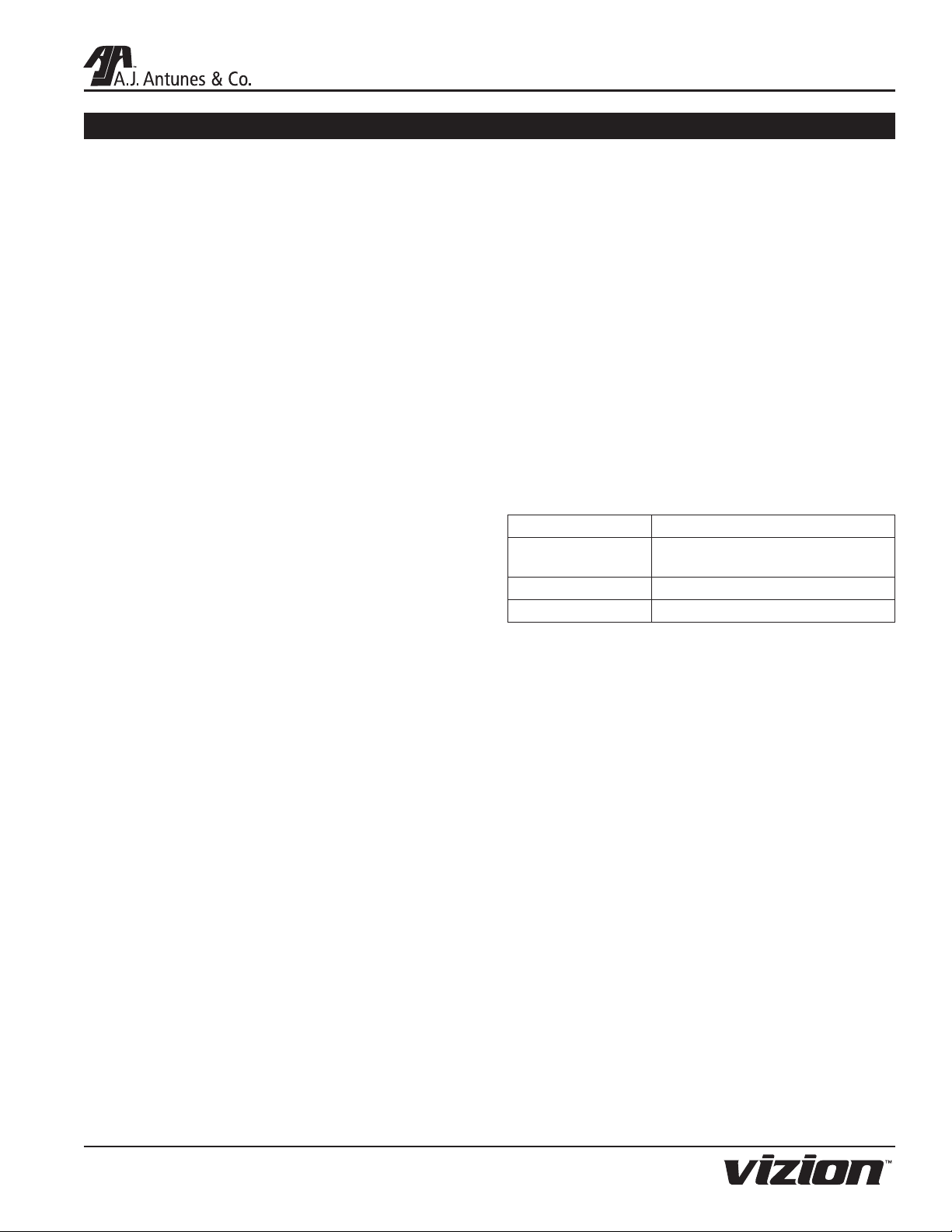

Maintenance........................................................................15

Replacing the Ultra Filter Cartridge.................................. 15

Rinsing and Replacing the Carbon Element.................... 16

Rinsing and Replacing the TAC Cartridge

(VZN-441V-T5 ONLY) ...................................................... 17

System Sanitization.......................................................... 17

Changing the Interval Setting........................................... 18

Resetting the Timer Program ........................................... 18

Check Permeate Tank Air Pre-Charge............................. 18

Troubleshooting .................................................................19

Replacement Parts .............................................................20

Notes....................................................................................23

Limited Warranty ................................................................24

General

The VZN system is an innovative filtration system that uses

proprietary multi-bore hollow fiber membranes as well as a

carbon element to provide the latest innovation in filtration

technology.

This manual provides the safety, installation, and

operating procedures for the VZN water filtration system. All

information contained in this manual should be read prior to

installing and operating the system. Your VZN system is man-

ufactured from the finest materials available and is assembled

to strict quality standards. This system has been tested at the

factory to ensure dependable trouble-free operation.

Warranty Information

Please read the full text of the Limited Warranty in this

manual.

If the system arrives damaged, contact the carrier immediate-

ly and file a damage claim with them. Save all packing materi-

als when filing a claim. Freight damage claims are the respon-

sibility of the purchaser and are not covered under warranty.

The warranty does NOT extend to:

• Damages caused in shipment or damage as result of

improper use.

• Installation of electrical service.

• Normal maintenance as outlined in this manual.

• Malfunction resulting from improper maintenance.

• Damage from moisture leaking into electrical

components.

• Damage from tampering with, removal of, or changing

any preset control or safety device.