4

OPERATION OF THESE FANS CAN PRODUCE A NEGATIVE

DRAFT IN THEAREA OF THE WATER HEATER PREVENTING

THE PRODUCTS OF COMBUSTION FROM EXHAUSTING

THROUGHTHE CHIMNEY OR VENT PIPE.

Theventing of the waterheater should be inspectedby a qualified

service technician at the time of installation and periodically

thereafter to ensure a down-draft condition does not exist.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATING AIR. ADEQUATE AIR FOR COMBUSTION AND

VENTILATIONMUSTBEPROVIDED FORSAFE OPERATION.

EXTENDED NON-USE PERIODS

WARNING

HYDROGENGASCANBEPRODUCEDINAHOTWATERSYSTEM

SERVEDBYTHISHEATERTHAT HAS NOTBEEN USED FORA

LONGPERIODOFTIME(GENERALLYTWO WEEKS OR MORE).

HYDROGEN GAS IS EXTREMELY FLAMMABLE. Toreduce the

risk of injury under these conditions, it is recommended that the

hot water faucet be opened for several minutes at the kitchen

sink before using any electrical appliance connected to the hot

water system. If hydrogen is present, there will probably be an

unusual sound such as air escaping through the pipe as the

water begins to flow. THERE SHOULD BE NO SMOKING OR

OPENFLAMENEARTHE FAUCETATTHETIMEITIS OPEN.

INSULATION BLANKETS

Insulation blankets available to the general public for external

use on gas water heaters are not approved for use on your

State water heater. The purpose of an insulation blanket is to

reduce the standby heat loss encountered with storage tank

water heaters. Your State water heater meets or exceeds

the ASHRAE/IES 90.1-1999 standards with respect to

insulation and standby loss requirement making an insulation

blanket unnecessary.

WARNING

Shouldyouchoosetoapplyan insulation blanket to this heater,

you should follow these instructions. Failure to follow these

instructions can result in fire, asphyxiation, serious personal

injury or death.

•Do not apply insulation to the top of the water heater, as

this will interfere with safe operation of drafthood.

•Do not cover the temperature & pressure relief valve.

•Do not cover the instruction manual. Keep it on the side of

the water heater or nearby for future reference.

•Do obtain new labels from State Water Heaters for

placement on the blanket directly over the existing labels.

HIGH ALTITUDE INSTALLATIONS

WARNING

INSTALLATIONS ABOVE 2000 FEET (610 METERS) REQUIRE

REPLACEMENTOF THE BURNER ORIFICE IN ACCORDANCE

WITH SECTION 8.1.2 OF THE NATIONAL FUEL GAS CODE

(ANSIZ223.1).FAILURETOREPLACETHEORIFICEWILLRESULT

INIMPROPERANDINEFFICIENTOPERATIONOFTHEAPPLIANCE

RESULTING IN THE PRODUCTION OF INCREASED LEVELS OF

CARBONMONOXIDEGASINEXCESSOFSAFELIMITSWHICH

COULDRESULTINSERIOUSPERSONALINJURYORDEATH.

You should contact your gas supplier for any specific changes

which may be required in your area.

As elevation above sea level is increased, there is less oxygen

per cubic foot of air. Therefore, the heater input rate should be

reduced at high altitudes for satisfactory operation with the

reduced oxygen supply. Failure to make this reduction would

result in an overfiring of the heater causing sooting, poor

combustion and/or unsatisfactory heater performance.

REQUIREMENTS

Ratings specified by manufacturers for most appliances apply

for elevations up to 2000 feet. For elevations above 2000 feet,

ratings must be reduced at the rate of 4% for each 1000 feet

above sea level. For example, if a heater is rated at

120,000 Btuh at sea level, to rate the heater at 4000 feet, you

subtract4 (once for each thousand feet) x.04(4% input reduction)

x120,000 Btuh(original rating) fromthe original rating. Therefore,

tocalculatethe inputrating at4,000 feet:4 x.04x 120,000=19,200

Btuh, 120,000 - 19,200 = 100,800 Btuh. At 6000 feet the correct

input rating should be 91,200 Btuh.

The input reduction is primarily achieved by reducing the size of

the main burner orifices. To do this, the main burner orifices

require replacement with orifices sized for the particular

installation elevation. Correct orifice sizing and parts may be

obtained from State Water Heaters. When ordering, be sure to

state the model number and the altitude of the location where

the water heater is being installed.

Upon completion of derating of the heater, adjustment to the gas

pressure regulator may be required. See CHECKING THE

INPUT section in this manual for inlet and manifold pressure

requirements.

Also due to the input rating reduction required at high altitudes,

the output rating of the appliance is also reduced and should be

compensated for in the sizing of the equipment for application.

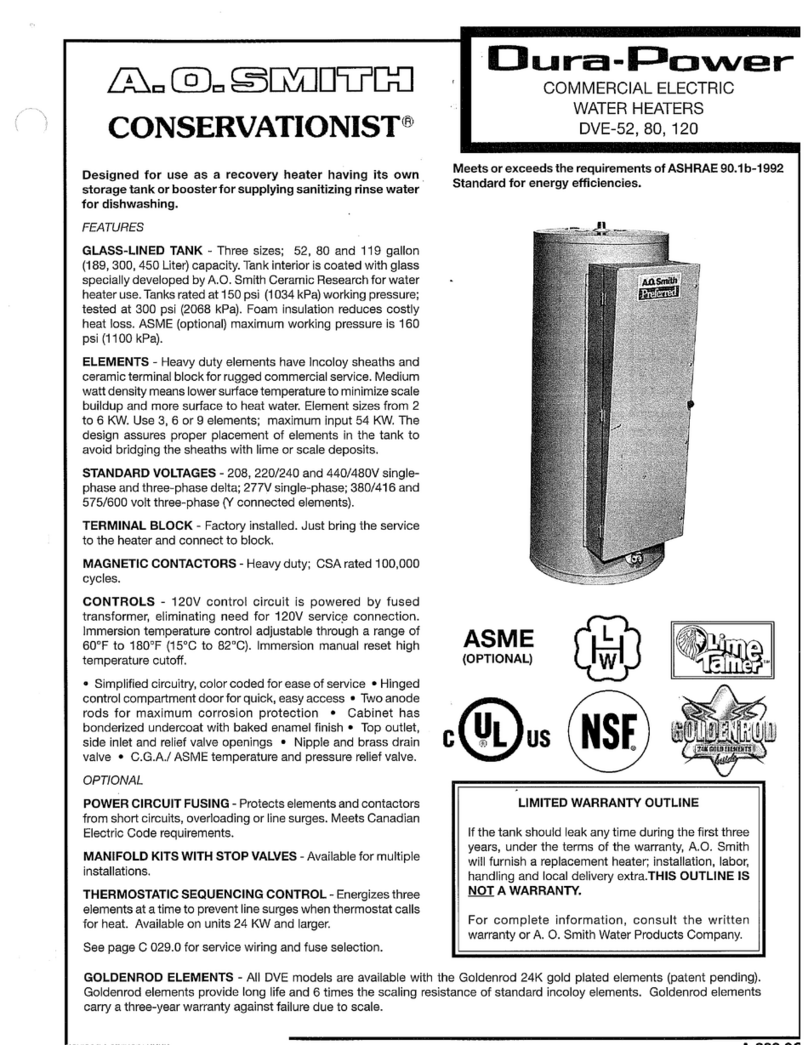

FEATURES

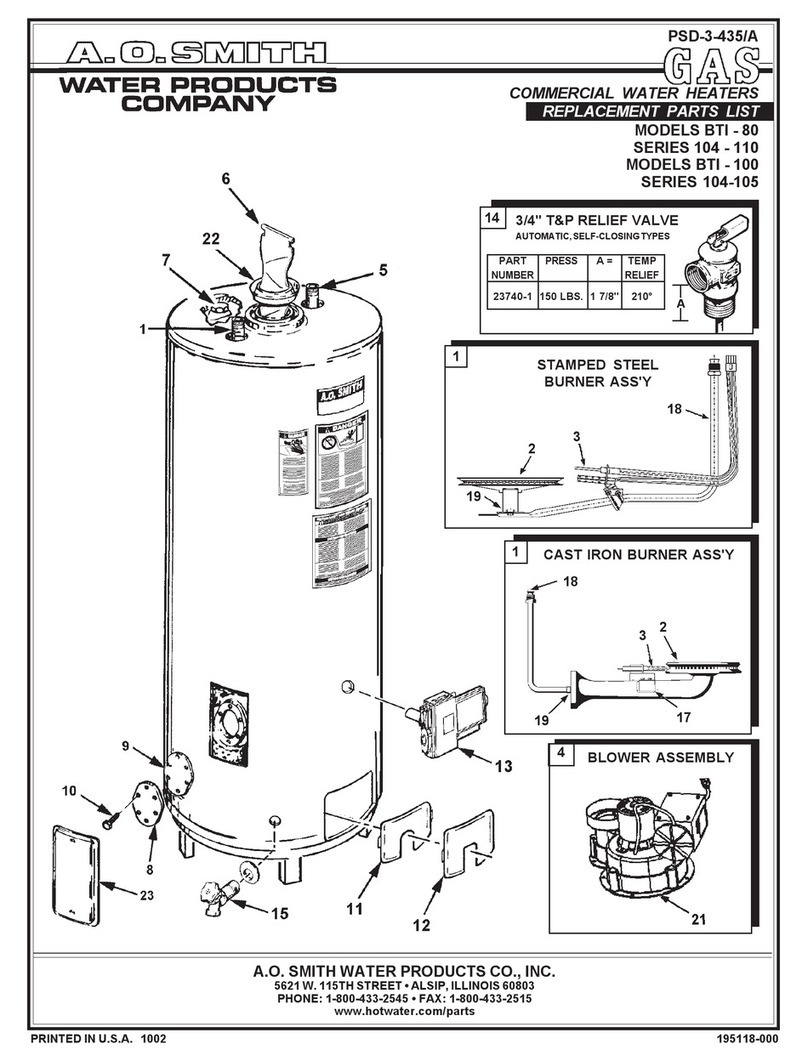

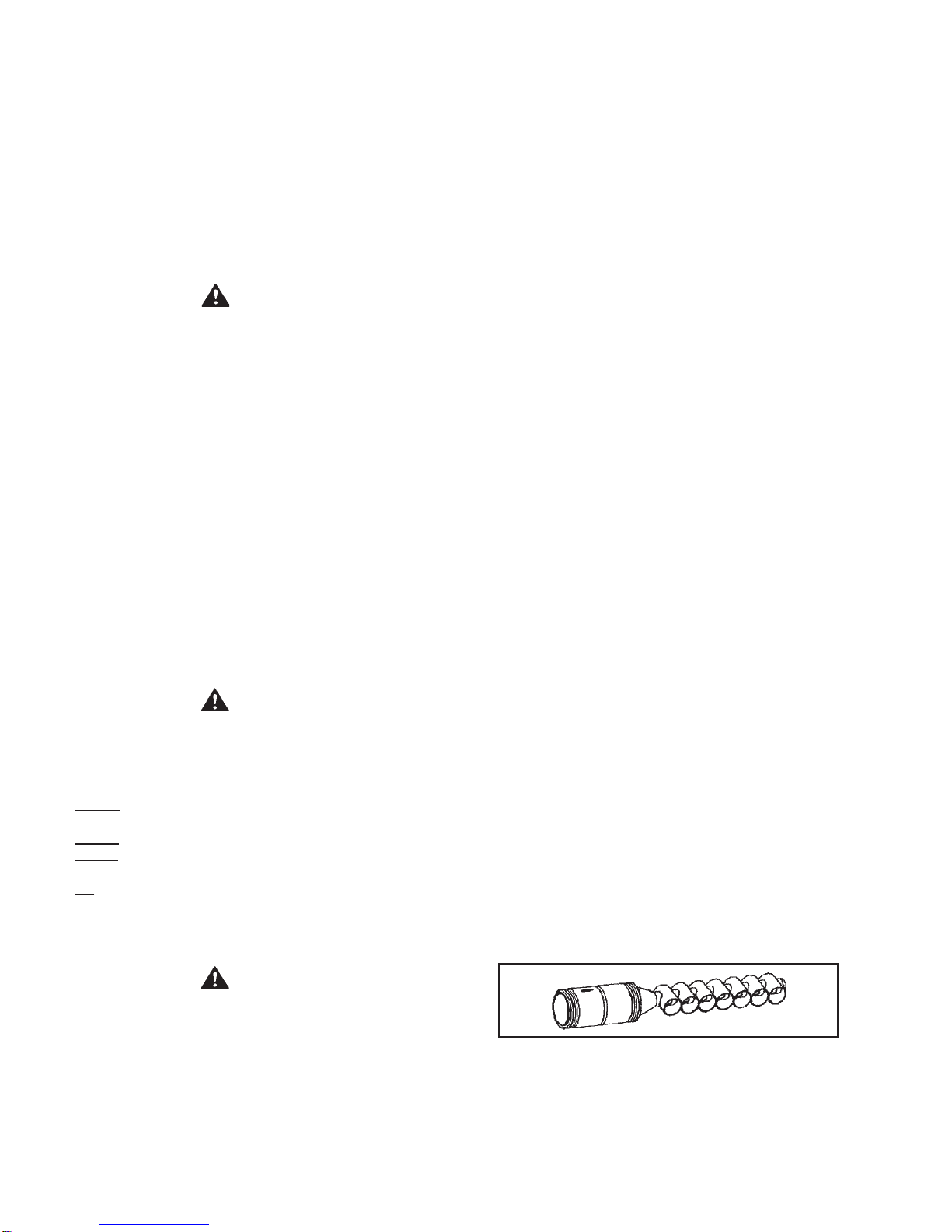

SELF-CLEANING HYDRO-CANNON

These units include a self-cleaning hydro-cannon installed in

the front water inlet. See figure 2. The hydro-cannon must be

oriented correctly for proper function. There is a marked range

on the pipe nipple portion of the hydro-cannon, that must be

aligned with the top of the inlet spud. A label above the jacket

hole has an arrow that will point to the marked portion of the

pipe nipple if the orientation is correct. If the arrow does not

point within the marked range on the pipe nipple, adjust the pipe

nipple to correct. Apipe union is supplied with the hydro-cannon

to reduce the probability of misaligning the hydro-cannon

accidentally while tightening the connection to the inlet water

supply line. Improper orientation of the hydro-canon can cause

poor performance of the heater and can significantly reduce

outlet water temperatures during heavy draws.

NOTE: The inlet may have 1, 2 or 7 cross- tubes.

FIGURE2

HIGH LIMIT SWITCH

The digital thermostat (Figure 3) contains the high limit (energy

cutoff) sensor. The high limit switch interrupts main burner gas

flow should the water temperature reach 203°F (195°C).