TABLE OF CONTENTS

Page

LIST OF SPECIFICATIONS…………………………………………. 6

INTRODUCTION……………………………………………………… 8

THEORY OF OPERATION………………………………………….. 8

Actuation Of Printing Mechanism…………………………… 8

Automatic Ribbon Advance……………………………………….. 10

Typewheel Operation……………………………………………… 11

OPERATING INSTRUCTIONS……………………………………… 13

Setting Print Wheels……………………………………………….. 13

Stamping An Impression…………………………………………… 14

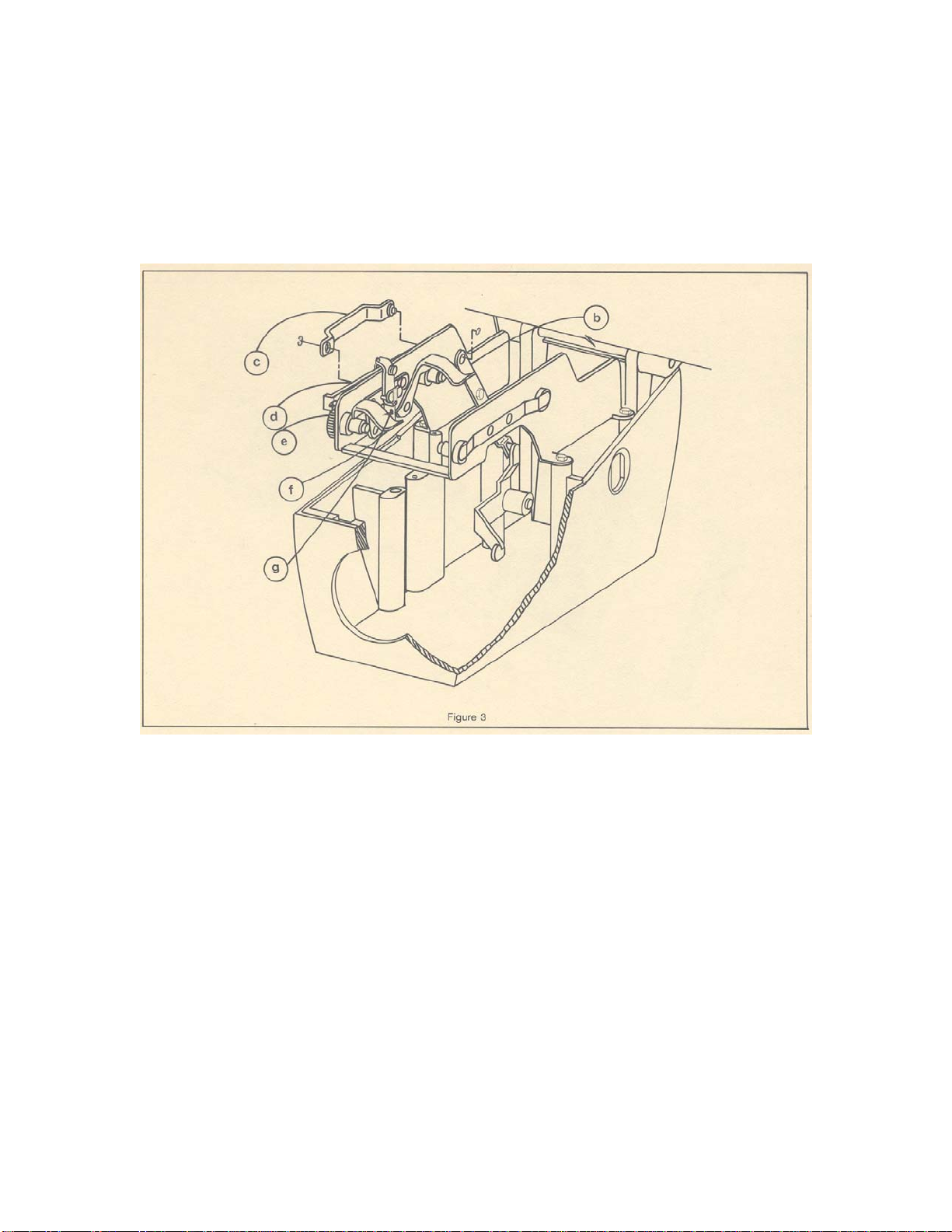

Description Of Major Assemblies………………………………….. 14

COMMON ADJUSTMENTS………………………………………….. 16

Changing Force Of Imprint………………………………………… 16

Imprint Location…………………………………………………… 16

Installation Of Extended Trigger……………………………… 19

Adjusting Uniformity Of Imprint……………………………… 19

TROUBLESHOOTING GUIDE………………………………………. 20

Machine Does Not Stamp………………………………………….. 20

Gains Time…………………………………………………………. 23

Loses Time…………………………………………………………. 24

Combination Test………………………………………………….. 26

Machine Does Not Stamp Or Advance……………………………. 26

Blowing House Fuses……………………………………………… 26

Ribbon Does Not Reverse…………………………………………. 26

AR-E Wiring Diagram……………………………………………... 27

AR-E w/Visual Counter Wiring Diagram………………………… 28

AN-E Wiring Diagram……………………………………………… 29

AN-E w/Repeat Switch Wiring Diagram……………………… 30

C724-E Wiring Diagram…………………………………………… 31

RECOMMENDED TOOLS…………………………………………… 32

RECOMMENDED LUBRICANTS…………………………………… 32

REPLACEMENT SPACERS………………………………………….. 33

MAINTENANCE………………………………………………………. 34

Changing Ribbon…………………………………………………… 34

Removing Typesection Assembly………………………………….. 35

Disassembling AR-E Typesection………………………………….. 35

Removing Motor……………………………………………….. 35

Removing Retaining Pawls/Springs/Shaft……………… 36

Removing Wheels And Swing Assembly……………………. 36

TABLE 1 Retaining Pawl Springs Color Code……………… 38

Removing Actuating Pawl Assembly………………………... 39

Changing A Unit Wheel………………………………………… 39

Disconnecting Typesection Wires……………………………… 41