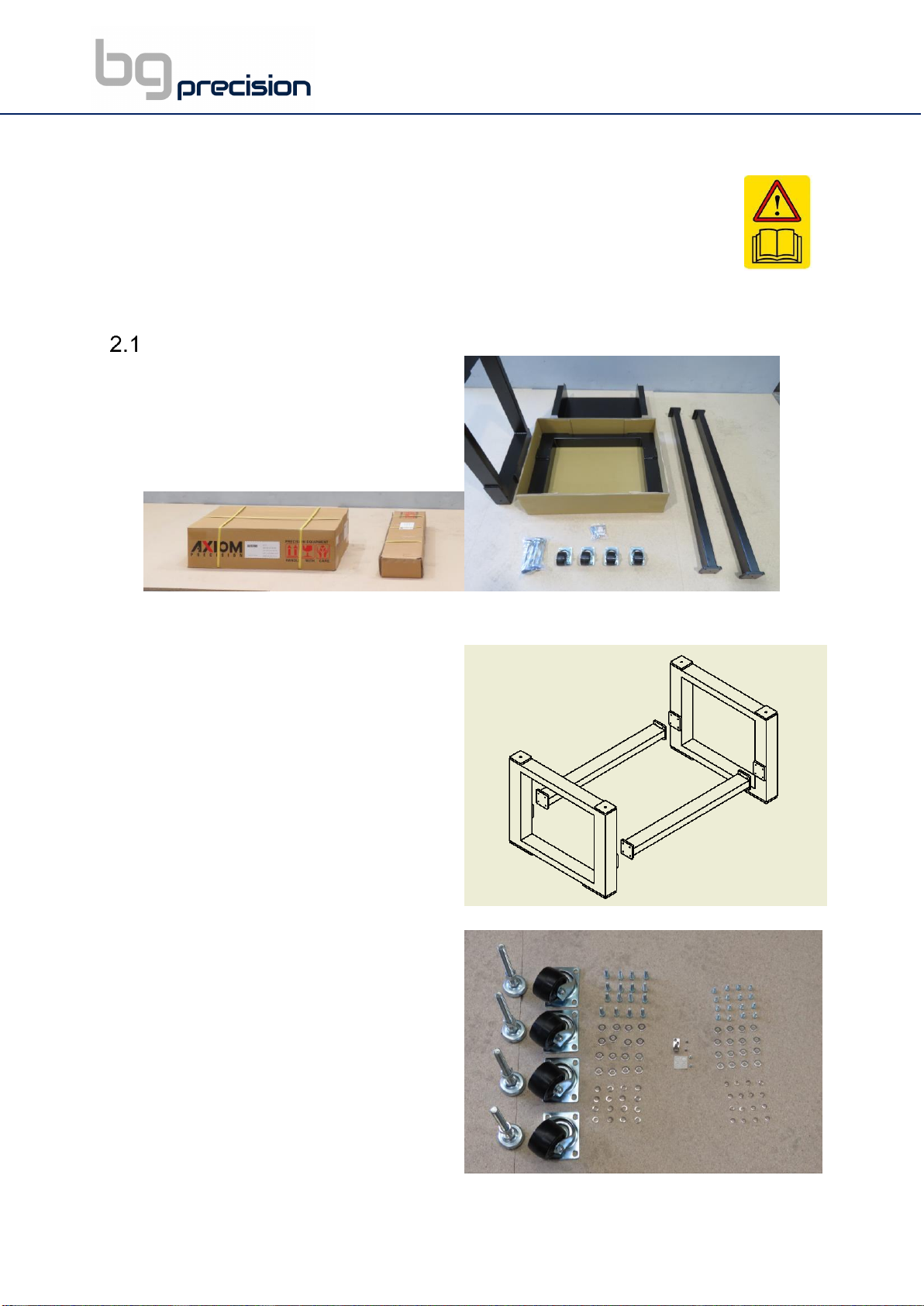

Remove all contents from shipping boxes. Do not discard carton or packing material until

assembly is complete. Accessories commonly ship inside machine or stand packaging and

can be easily over looked.

STAND ASSEMBLY

Tools required for assembly:

#2 Philips-Screwdriver

10mm, 13mm and 17mm sockets and socket wrench

24mm open-end wrench

2mm and 3mm Allen key

Spirit Level

Assembling Stand (all models):

Assembly for stand fitting all Basic and Pro model machines is the same. The only difference

is the length of the cross braces.

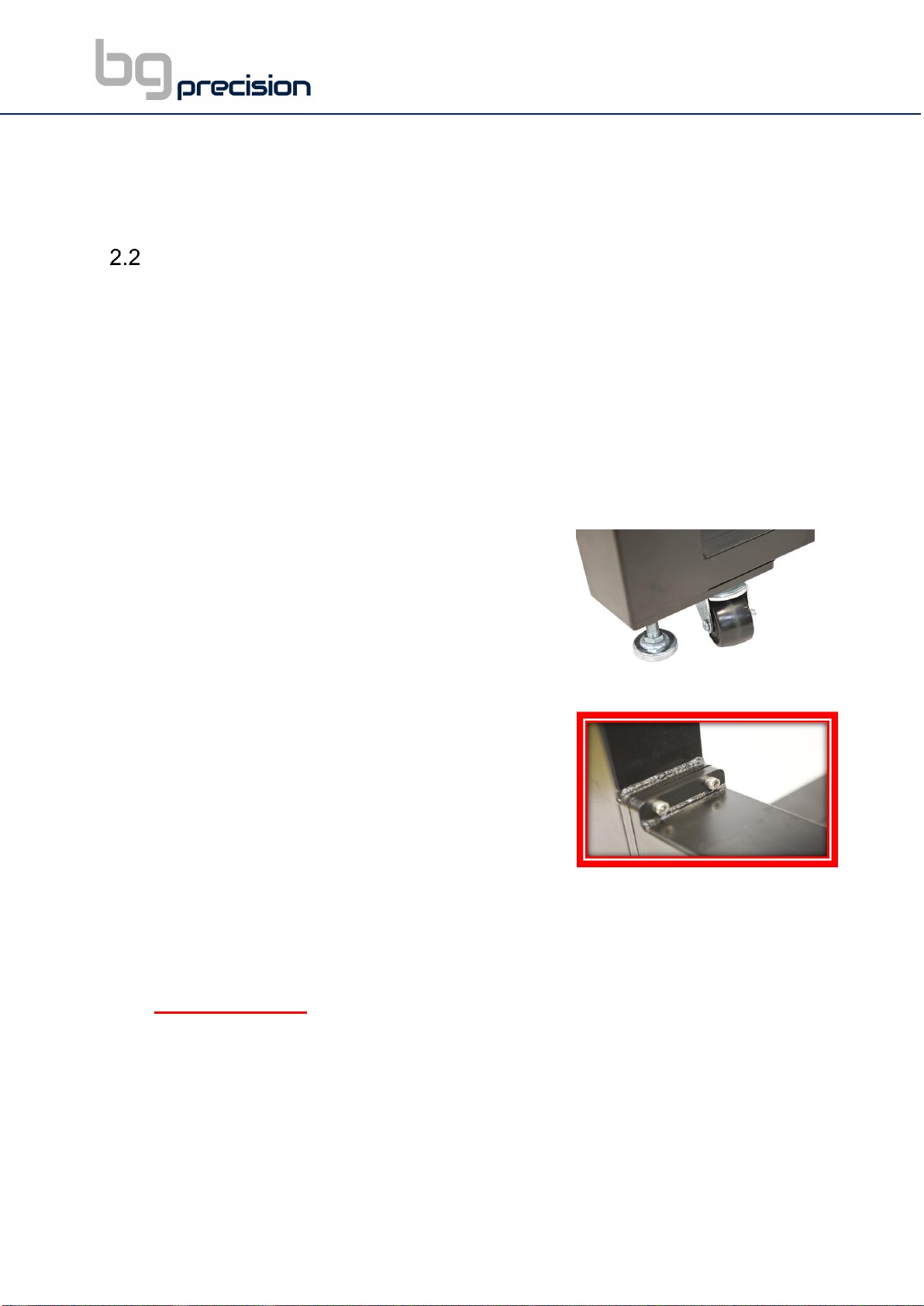

1- Thread a loose hex-nut onto each of the levelling feet.

2- Turn the square stand uprights upside down. Do this on

top of the cardboard packaging to prevent scratching.

a. Install the levelling feet and swivel casters using

M6 hex bolt, M6 lock washer, and M6 flat washer

for each caster. Tighten all the caster hardware

securely. The levelling feet can be adjusted later.

b. Rotate uprights so the cross-brace mounting plates

are facing each other. Separate the uprights far

enough that the braces can fit between them.

c. Align the cross-braces between the uprights and

bolt the mounting flanges to the plates using (4) M8

hex bolt, (4) lock washers and (4) flat washers for each side. We recommend that

you do not fully tighten these bolts until the machine is securely fixed on top of the

stand as this makes the machine and stand alignment easier.

IMPORTANT NOTE: As seen in the diagram above (Figure 9), the braces should be

rotated correctly for the toolbox and shelf to sit at the correct height. Braces

should be mounted so that the top and bottom are the larger flat surfaces*

3- With assistance, the stand can now be flipped over onto the casters and levelling feet.

4- Flip the shelf upside down and stick of the rubber pads on each corner of the shelf flange.

a. Install shelf between the braces on the stand, all the way forward.