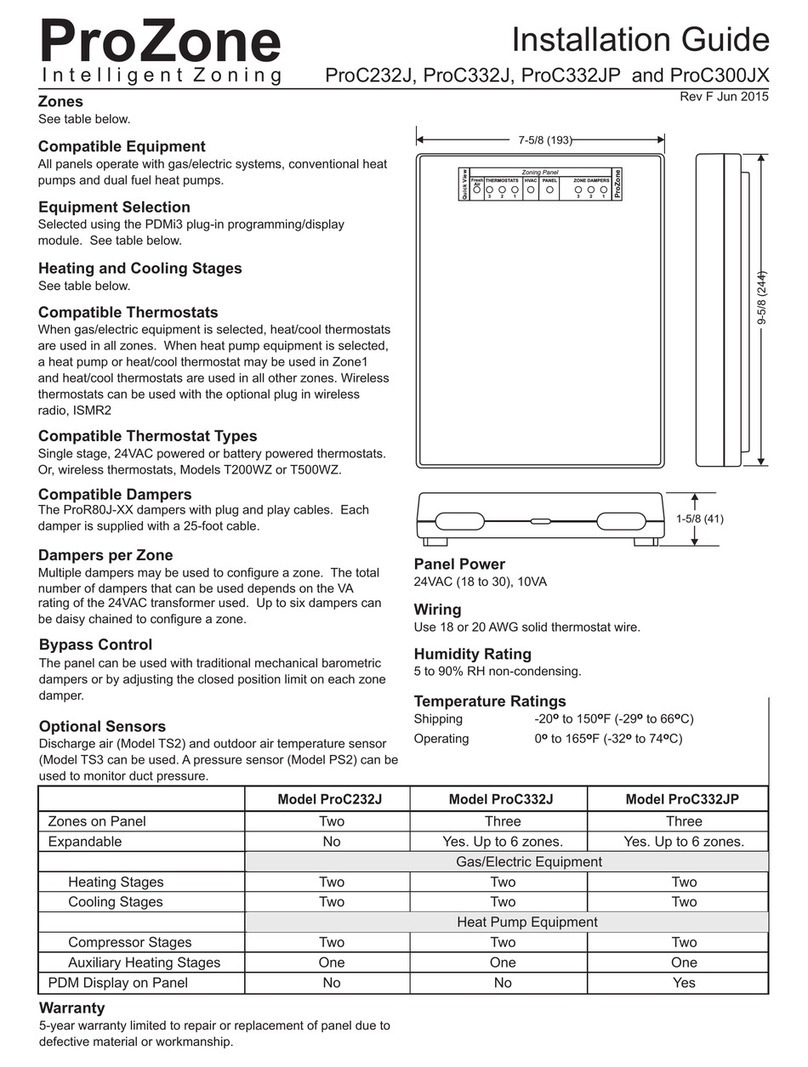

12

A damper can be used to bring outdoor air into the return to

maintain a healthy home. The equipment fan draws in the

outdoor air and mixes it with the return air from the home.

The panel attemps to fulfill the required fresh air during

heating and cooling calls. As the end of each hour

approaches, the panel will open the fresh air damper and

activate the indoor fan (G) if additional fresh air minutes are

required.

The PDMi3 allows the installer to directly set the minutes

per hour the fresh air damper is open or the PDMi3 can

calculate the required CFM of fresh air based on the area

of the home and the number of bedrooms.

Fresh air operation is factory set to Off.

If the contractor has calculated the CFM for fresh air and sized

the damper to operate for a number of minutes each hour, the

minutes can be directly entered.

The PDMi3 allows the installer to calculate the required CFM of

fresh air based on the area of the home and the number of

bedrooms. The calculated CFM is the CFM required if the fresh

air damper is continuously open and the indoor fan operating to

draw in fresh air.

The PDMi3 tutors the installer to set the area of the home in

square feet and the number of bedrooms. It then calculates and

displays the minimum amount of outdoor air required to meet the

requirement for the home. This is the amount required if the

indoor fan was running continuously.

If the fresh air intake is increased, the fresh air operation can

occur mostly during calls to minimize dis-comfort. The PDMi3 will

then display the number of minutes of fresh air operation required

each hour based on the minimum CFM and the selected CFM.

Fresh Air Control for Title24 and ASHRAE 62.2

Change or Set Fresh Air Operation

Direct Entry of Minutes per Hour of Fresh Air

PDMi3 Calculates Minutes per Hour of Fresh Air

Press Up or Down to set the area of

the home. Press NEXT to continue.

Press Yes to have the PDMi3 calculate

the fresh air requirements. Press No to

directly set the minutes per hour of fresh

air operation.continue.

Press Up or Down to set the

number of minutes the fresh air

damper and indoor fan must

operate each hour to meet the fresh

air requirements. Press NEXT to

continue.

Press Yes to enter the minutes of

fresh air operation required each

hour. Press No to select calculating

the CFM and minutes per hour.

Press Yes to change the Fresh Air

Option. Press no to continue to

another option.

Press Yes to turn the Fresh Air

Option On or No to turn it Off.

Press Up or Down to set the

bedrooms in the home. Press NEXT

to continue.

The PDMi3 shows the minimum CFM

required when the fresh air duct is

operating continuously.

Press Up or Down to adjust the fresh

air CFM. Increasing the CFM to 210

would lower the number of minutes

per hour of fresh air operation

allowing it to be accomplished during

calls. Press NEXT to continue.

The PDMi3 shows the number of

minutes of fresh air operation each

hour. Press Up or Down to adjust the

fresh air minutes each hour. Press

NEXT to continue to the next menu

selection.

Fresh Air Calc

Y/N

Fresh Air Enter

Min/Hr Y/N

Change Fresh Air

Option Y/N

Fresh Air Off

Y-On/N-Off

Area 2200

SqFt U/D/NEXT

Bedrooms 4

U/D/NEXT

Fresh Air 70

CFM U/D/NEXT

Fresh Air 20

Min/Hr U/D/NEXT

Fresh Air 20

Min/Hr U/D/NEXT

Fresh Air 210

CFM U/D/NEXT

Press Yes to select limiting upstaging

based on outdoor temperature.

Staging is controlled by the number of minutes heating or

cooling has been calling. The Timer monitors the continuous

call time and forces staging when the call time exceeds the

preset limits.

Staging can be disabled if the outdoor temperature exceeds

the preset limits.

Limit Staging Based on Outdoor Temperature

Press Yes to select timed upstaging.

Press Up or Down to set the number

of minutes of continuous call time

required to upstage to Stage2. Press

NEXT to continue.

Press Up or Down to set the number

of minutes of continuous call time

required to upstage to Stage3. Press

NEXT to continue to the next menu

selection.

Press Up or Down to set the outdoor

temperature to disable staging

heating. If the outdoor temperature is

above the limit, staging of heating is

disabled. Press NEXT to continue.

Press Up or Down to set the outdoor

temperature to disable staging

cooling. If the outdoor temperature

is below the limit, staging of cooling

is disabled. Press NEXT to continue

to the next menu selection.

Staging Based on Call Timer

Timed

UpStaging Y/N

Stage 2 20

Minutes U/D/NEXT

Stage 3 30

Minutes U/D/NEXT

Limit Staging

OD Temp Y/N

OD Temp Lmt 60

Heating U/D/NEXT

OD Temp Lmt 55

Cooling U/D/NEXT