A-TS TECHNOLOGY DT100-2S0004G User manual

A-TS 1

https://a-ts.cn/en/

DT100 Series Inverter/VFD/AC

Drive User Manual

A-TS TECHNOLOGY

CORPORATION LIMITED

A-TS 2

https://a-ts.cn/en/

DECLARATION

Without written permission, reprint or copy is strictly forbidden.

A-TS Technology Corporation Limited

All rights reserved

Version

Product

Realse Date

Note

V-18-02

DT100

27.11.2018

N/A

A-TS 3

https://a-ts.cn/en/

Contents

DECLARATION.....................................................................................................2

1. Foreword..........................................................................................................6

2. Inspection ........................................................................................................7

3. Safety Precautions..........................................................................................8

3.1 Safety definition ............................................................................................8

3.2 Safety items ...................................................................................................8

3.3 Precautions..................................................................................................12

4. Specifications and Optional Parts ...............................................................16

4.1Specifications...............................................................................................16

4.2 Products Series Introduction .....................................................................17

4.2.1 DT100 Models....................................................................................17

4.2.2 Ordering information of DT100 series ................................................18

4.2.3 Demision............................................................................................19

4.2.4 LED Keypad Display Unit Size...........................................................19

4.2.5 Optional Parts ....................................................................................20

5. Installation and Wiring..................................................................................21

5.1 Installation ...................................................................................................21

5.2 Wiring...........................................................................................................22

5.2.1 Overview............................................................................................22

5.2.2 Power Terminals.................................................................................23

5.2.3 Control Circuit Wiring.........................................................................23

6. Operation Procedures...................................................................................30

6.1 Operation Guide ..........................................................................................30

LED Keypad................................................................................................30

6.1.1 Keypad Function Explanation ............................................................30

6.1.2 Indicator Description ..........................................................................31

6.1.3 Parameter Setting Method .................................................................32

6.1.4 Motor parameters self learning...........................................................32

6.1.5 Password setting................................................................................33

7. Parameters.....................................................................................................34

A-TS 4

https://a-ts.cn/en/

7.1 Basic Parameters ( P0 ) .............................................................................34

7.2 Motor Parameter ( P1 ) ..............................................................................37

7.3 Start/Brake Parameter ( P2 ) .....................................................................39

7.4 Flux vector control parameters ( P3 ) ......................................................41

7.5 Current vector control parameter ( P4 ) ...................................................44

7.6 Multi-function terminal ( P5 ) ....................................................................44

7.7 Output terminal control parameters ( P6 ) ...............................................51

7.8 Closed-loop PID control ( P7 ) ..................................................................56

7.9 MS parameters ( P8 ) .................................................................................59

7.10 Enhanced function ( P9 ) .........................................................................59

7.11 Display Control Parameters ( PA ) ..........................................................63

7.12 Communication ( PB ) .............................................................................64

7.13 Professional parameters ( PC ) ..............................................................66

7.14 PLC parameters ( PD ) .............................................................................66

7.15 Constant-pressure water supply ( PE ) ...............................................69

7.16 Protection ( PL ) .......................................................................................69

7.17 Operation Time and Temperature of Cooling Fan ( PN ) ....................72

7.18 Protection of Parameters ( PP ) ..............................................................72

7.19 Factory Default ( PU ) ..............................................................................73

8. Trouble shooting...........................................................................................74

9. Maintenance...................................................................................................83

9.1 Routine Maintenance ..................................................................................83

9.2 Periodic Maintenance..................................................................................84

9.2.1 General Inspection:............................................................................84

9.2.2 Replacing Easily-worn Parts ..............................................................85

A-TS 5

https://a-ts.cn/en/

9.2.3 Storing Inverters.................................................................................86

9.2.4 Warranty.............................................................................................86

10. Parameter profiles.......................................................................................87

11. Communication Protocal..........................................................................121

11.1 Communication Mode.............................................................................121

11.2 Protocol Format.......................................................................................121

11.3 Protocol Function....................................................................................122

11.4 Instruction................................................................................................128

11.5 The scaling rule of Inverter.....................................................................129

A-TS 6

https://a-ts.cn/en/

1. Foreword

The DT100 series inverter is provided by A-TS Technology Co., Ltd.

in China.

With the unique control method, high torque, high accuracy and wide

speed-adjusting range, DT100 series satisfies high performance

requirements. It has anti-tripping function and capabilities of adapting

severe power network, temperature, humidity, and dusty environment,

which improves the products reliability markedly.

This manual provides guidance on installation, wiring, parameters

setting, trouble-shooting, and routine maintenance, etc.. In order to

ensure the correct installation and operation of the inverter, please read

this manual carefully before use and keep it safely.

Thank you for choosing A-TS.

A-TS, advanced technologies, advanced things.

A-TS 7

https://a-ts.cn/en/

2. Inspection

Product Overall Checking

Don’t install or use any inverter that is damaged or have defective parts,

otherwise it may cause injury !

Check the following items when unpacking.

1. Check the nameplate, make sure inverter model matches your order.

The box contains the inverter and user manual.

2. Inspect the whole exterior of inverter to ensure there are no scratches

or other damage caused by transportation. If the inverter is damaged

during transportation, or you find any missing or damage, please contact

A-TS or your local supplier immediately.

3. If you have ordered optional parts, ensure the optional parts match

your order.

If there is any damage in the inverter or other parts, please contact the

local supplier or A-TS as early as possible.

A-TS 8

https://a-ts.cn/en/

3. Safety Precautions

To have a thorough understanding, please read this manual carefully

and follow all safety precautions before moving, installing, operating and

servicing the inverter. If it’s ignored, physical injury or even death may

occur, and damage may occur to the devices.

For any injury or loss caused by improper operation, A-TS will not

take the responsibility.

3.1 Safety definition

In this manual, the safety precautions are sorted to “Danger” or

“Caution”

DANGER

Operations without following instructions may cause fire, severe

injury, or even death.

Operation without following instructions may cause medium or

minor injury or property damage.

3.2 Safety items

Before installation:

DANGER

Please do not install the equipment if you find water seepage,

component missing or damage upon unpacking.

Do not install the equipment if the packing list is not conform to the

product you received.

Please use the insulating motor above B class; otherwise it may

result in serious injury or even death due to electric shock !

Please do handle the equipment carefully during transportation to

prevent damage to the equipment.

Do not touch the components with your hands directly. Improper

operation will result in static electricity damage.

!

CAUTION

!

CAUTION

A-TS 9

https://a-ts.cn/en/

During installation:

DANGER

Please install the inverter on the fireproofing material ( such as

metal ) to prevent fire, and keep it away from combustible materials !

Do not loosen the fixed screws of the components.

When you need to install two or more inverters in one cabinet,

cooling fans should be provided,and the installation positions should be

arranged properly to make sure that the ambient temperature is below

45℃. Otherwise it could cause fire or damage to the devices.

Install the inverter in places without vibration or direct sunlight.

Do not drop any wire end or screw into the inverter. Failure to

comply will result in damage to the inverter.

At wiring:

DANGER

Wiring must be performed only by qualified personnel under

instructions in this manual. Improper operation may cause unexpected

accidents.

A circuit breaker must be used between the power supply and

inverter to isolate. Otherwise the fire may be caused !

Never wire the inverter unless the power supply is totally cut off !

The ground terminal must be grounded properly by standard to

avoid electrical accident !

Pay attention to the marks of the wiring terminals and ensure

correct wiring. Never connect the power cables to the output terminals

( U,V, W ) of the inverter.Otherwise it will cause damage to the inverter !

The wring must comply with the EMC requirements and safety

standards in the region. Use wire diameter sizes recommended in the

manual, otherwise it may cause an accident !

Use the shielded cable for the encoder, and ensure that the

!

CAUTION

!

CAUTION

A-TS 10

https://a-ts.cn/en/

shielding layer is reliably grounded.

Never connect the braking resistor between the DC bus terminals

( + ) and ( - ) , or it may cause a fire !

Before power-on:

DANGER

Make sure the following requirements, failure to comply will cause

damage to the inverter.

–The power and voltage level of the power supply is consistent with

the rated voltage of the inverter.

–The input terminals ( R, S, T ) and output terminals ( U, V, W )

are properly connected.

–No short-circuit exists in the peripheral circuit.

–The wiring is secured.

Do install the cover properly before power-on, to prevent the

danger of electric shock !

Do not perform the voltage resistance pressure test on any part of

the inverter, because such test has been done in the factory. Otherwise, it

will cause accidents.

All the peripheral devices must be connected properly under the

instructions in this manual. If not, it may cause an accident !

After power-on:

DANGER

Do not open the cover after power-on, otherwise it may cause

electric shock and damage !

Do not wire or operate the inverter with wet hands, otherwise it

may cause electric shock !

Do not touch any inverter terminals ( including the control

terminals ) , otherwise it may cause electric shock !

At the beginning of power-on, the inverter will carry out safety

testing for external electric circuit automatically. Do not change the

!

CAUTION

A-TS 11

https://a-ts.cn/en/

default settings of the inverter. Otherwise it will cause damage to the

devices.

If you need parameter identification, please notice the risk of

injuries in motor rotation. Do not touch the rotating part of the motor

during the motor auto-tuning or running. Or, it may cause an accident !

Please do not arbitrarily change the default parameters of inverter;

otherwise it may result in equipment damage !

During operating:

DANGER

When the user selects the function re-starting, please do not stay

close to the mechanical equipment, otherwise it may cause personal

injury !

Do not touch the radiator, fan or the discharging resistor to check

the temperature, otherwise it may get burned !

Only qualified personnel shall detect the signal, otherwise it may

cause personal injury or equipment damage !

When the inverter is running, please don’t let any sundries fall into

the device, or it may cause equipment damage !

Please do not start/stop the AC drive by turning the contactor

ON/OFF, otherwise it would cause device damage !

During maintenance:

DANGER

Ensure the inverter is disconnected from all power supplies before

starting repair or maintenance. Never repair or maintain the inverter with

electrification, otherwise it may cause injury or electric shock !

Do not repair or maintain the inverter when power-on. Before the

maintenance or repair, wait at least ten minutes after power off and ensue

the inverter “CHARGE” light off, otherwise the residual charge on the

capacitor may cause personal injury !

!

CAUTION

!

CAUTION

A-TS 12

https://a-ts.cn/en/

Only qualified personnel can repair and maintain the inverter,

otherwise it will cause personal injury or device damage!!

Set and check the parameters again after the inverter is replaced.

Only after power-off, the pluggable components can be plugged or

removed.

Generally, the rotating motor feeds back power to the inverter.

Ensure the inverter is disconnected from the motor before starting repair

or maintenance.

3.3 Precautions

Insulation of the motor

Before using the inverter, the insulation of motor must be checked,

especially, when it is used for the first time or it has been stored for a long

time. The poor insulation of the motor winding may cause damage to the

inverter. The motor must be disconnected from the inverter during the

insulation test. Please use 500V insulation tester to measure the

insulation resistance. It should not be less than 5MΩ.

Thermal protection of the motor

In model selection, if the rated capacity of motor and inverter does not

match, especially when the rated power of inverter is greater than the

motor, make sure to adjust the motor protection-related parameters in the

inverter or the pre-installed thermal relay in the motor for motor thermal

protection.

Working above power frequency

The inverter can provide 0Hz-60Hz output frequency, if the customer

needs to run at 50Hz or above, please consider the affordability of

mechanical devices.

Vibration of mechanical devices

When the inverter output frequency reaches a certain value, you may

encounter a mechanical resonance point of the load devices. It can be

avoided by setting parameters about the hopping frequency in the

inverter.

Regarding motor heat and noise

A-TS 13

https://a-ts.cn/en/

Because the output voltage of the inverter is the PWM wave,it

contains some harmonics wave, Therefore, there will be some increase in

temperature、noise、libration in motor and work-frequency.

Varistors for surge protection and capacitors used to improve the

Power Factor

Don’t connect any varistor or capacitor to the output terminals of the

inverter, as the inverter output voltage waveform is pulse wave.

Otherwise, it may cause tripping or damage to devices.

If the circuit breaker or contactor needs to be connected between

the inverter and the motor, please only operate them when the inverter

has no output. Do not turn off the contactor when the inverter is active. It

is to avoid damage to the inverter. Otherwise it may cause damage to the

devices.

Using outside rated voltage

The inverter could not be used at an operating voltage out of the

specified range. If needed, please use suitable voltage regulation device.

Try to change the three-phase input into two-phase input

It’s not permitted. Don’t use the three-phase inverter as a two-phase

one, or it will result in failure or damage.

Protection against lightning stroke

There are transient surge suppressors inside the inverter. They can

protect it against lightning stroke. If it is in frequent lightning stroke area,

more protection device should be added in the leading end.

Derating due to altitude

Derating must be considered when the inverter is installed at a

high altitude, above 1000m. The cooling effect of the inverter is less

effective in the thin air. For more details, please contact your local

supplier or A-TS.

For some special usages

If the customer needs to use the wiring diagram that the manual

did not mentioned, such as the common DC bus, please contact local

supplier or A-TS.

A-TS 14

https://a-ts.cn/en/

Disposing unwanted inverters

1 ) The capacitors and PCB may explode when they are burnt.

2 ) Poisonous gas may be generated when the plastic parts like front

covers are burnt.

3 ) Please dispose the inverter as industrial refuse.

Requirement on residual current device ( RCD )

The inverter generates high leakage current during running, which

flows through the protective earthing ( PE ) conductor. Thus it is

necessary to install a type-B RCD at primary side of the power supply.

When selecting the RCD, you should consider the transient and

steadystate leakage current to the ground that may be generated at the

inverter startup and running. You can select a specialized RCD with the

function of suppressing high harmonics or a general-purpose RCD with

relatively large residual current.

High leakage current warning

The inverter generates high leakage current during running, which

flows through the PE conductor. Earth connection must be done before

connection of power supply. Earthing shall comply with local regulations

and related IEC standards.

Surge suppressor

The inverter has a built-in voltage dependent resistor ( VDR ) for

suppressing the surge voltage generated when the inductive loads

( electromagnetic contactor, electromagnetic relay, solenoid valve,

electromagnetic coil and electromagnetic brake ) around the inverter

are switched on or off. If the inductive loads generate a very high surge

voltage, use a surge suppressor for the inductive load or also use a

diode.

Do not connect the surge suppressor on the output side of the

inverter.

Adaptive motor

1 ) The standard adaptive motor is four-pole squirrel-cage

asynchronous induction motor. If it is not the motor mentioned above,

A-TS 15

https://a-ts.cn/en/

customer could select the inverter according to rated current of the motor.

If you need the inverter matches permanent magnet synchronous motor,

please ask local supplier or A-TS for support.

2 ) The cooling fan of non-variable frequency motor and the rotor

shaft is connected by coaxial connection device. The fan cooling effect

decreases along with the rotational speed. Therefore, when it’s

overheated, more fan should be installed or change to use the variable

frequency motor.

3 ) There are built-in standard adaptive parameters for motors in the

inverter. According to the actual situation or requirements, motor

parameter recognition ( auto-tuning ) needs to be performed or

unique default value should be set, in order to match with the actual

conditions as far as possible. Otherwise it will affect the running

performance and protection capability.

4 ) If the short circuit occurs in the cable or motor, it will cause alarm in

the inverter, or even explosion. Therefore, firstly please do perform the

insulation and short circuit tests, when the motor and cable are initially

installed. The same tests should also be carried out in the routine

maintenance regularly. Please kindly note that the inverter should be

separated totally, when doing such tests.

A-TS 16

https://a-ts.cn/en/

4. Specifications and Optional Parts

4.1 Specifications

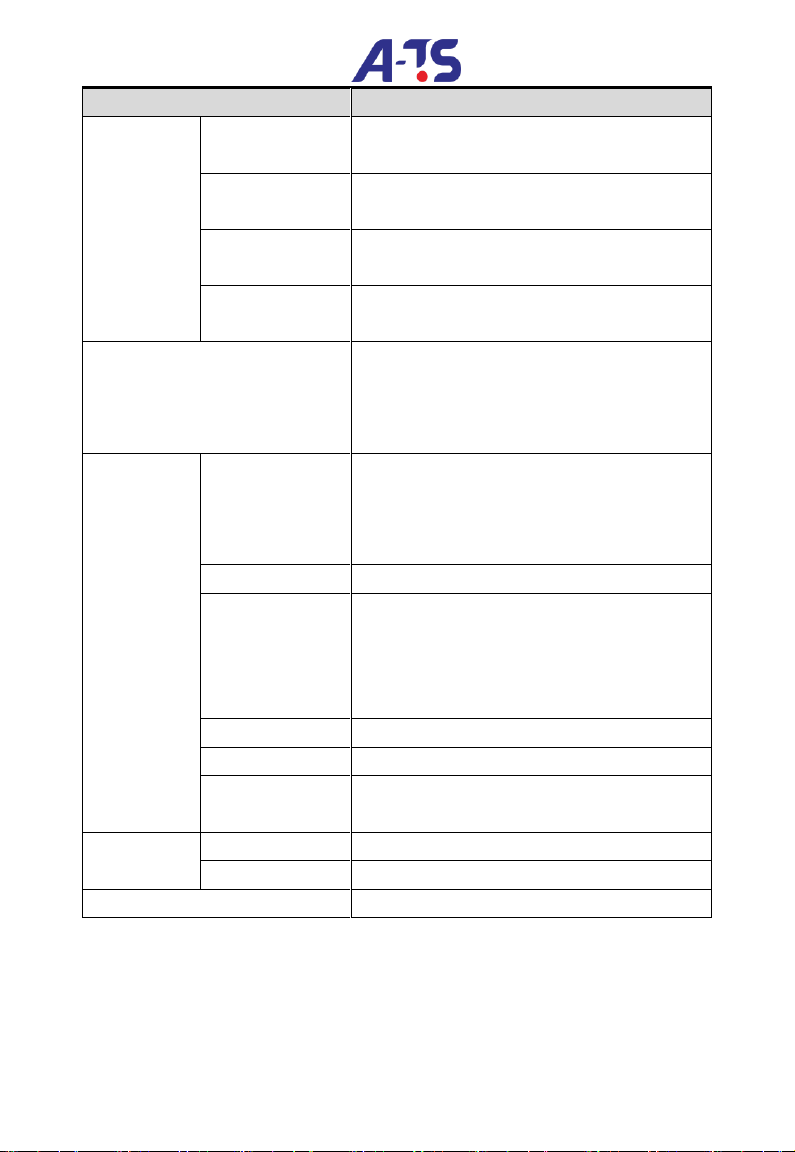

Table 4-1 DT100 Specifications

Item

Description

Input

Rated voltage;

Frequency

DT100-4Txxxxx: 380V~440V; 50Hz/60Hz

DT100-2Sxxxxx: 200V~240V; 50Hz/60Hz

Permissible

fluctuation range

Voltage contant fluctuate ≤±10%, Transient

fluctuate: -15%~+10%, out of balance voltage

rate: ≤3%, frequency fluctuation:≤5%

Output

Rated voltage

DT100-4Txxxxx: 0~380V/440V

DT100-2Sxxxxx: 0~200V/240V

Frequency

0Hz~650Hz

Control

functions

Modulation mode

Flux vector PWM modulation

Speed range

1: 100

Starting torque

180% rated torque at 0.5Hz

Accuracy of speed

at steady state

≤±0.5%rated synchronous speed

Torque boost

Auto torque boost, Manual torque boost

Acc/Dec curve

Linear

Jog

Jog frequency, Acc/Dec time,

Jog interval are adjustable

Multi-speed

operation

15 sections of frequency. By the built-in PLC or

terminals.

Closed-loop

control

Analog closed-loop

Auto voltage

regulation

( AVR )

Steady output voltage,

when power network voltage fluctuates.

Auto current

regulation

Current amplitude is regulated

to avoid overcurrent automatically

Auto carrier

regulation

Adjust the carrier frequency automatically,

according to the load characteristics

Special

Internal counter

External pulse signal is counted by X terminal

A-TS 17

https://a-ts.cn/en/

Item

Description

function

Command

channel

Via operation panel, terminals and serial port

Frequency setting

channel

Digital setting, AIand communication

Auxiliary

frequency setting

Flexible auxiliary frequency selectable

Analog output

terminals

0/4~20mA and 0/2~10V ( selectable )

Protection function

Phase loss failure protection, Over/Under

current protection,

Over/Under voltage protection,

Overheat and overload protection.

Environment

Operating

environment

In-door, no direct sunlight, no dust, no corrosive

gas or

combustible gas,no oil mist, vapor, drip, or

salinity.

Altitude

Less than 1000m ( Above 1000m derating )

Ambient

temperature

-10℃~+40℃, derating is required from 40~

50℃;

Above 40℃, each degree rised, derating 2%;

Highest temperature: 50℃.

Humidity

Less than 95% RH, no condensing

Vibration

Less than5.9m/s2( 0.6g )

Storage

temperature

-40℃~+70℃

Enclosure

Protection level

IP20

Cooling

Fan cooling, natural cooling

Mounting mode

Mounted in the cabinet

4.2 Products Series Introduction

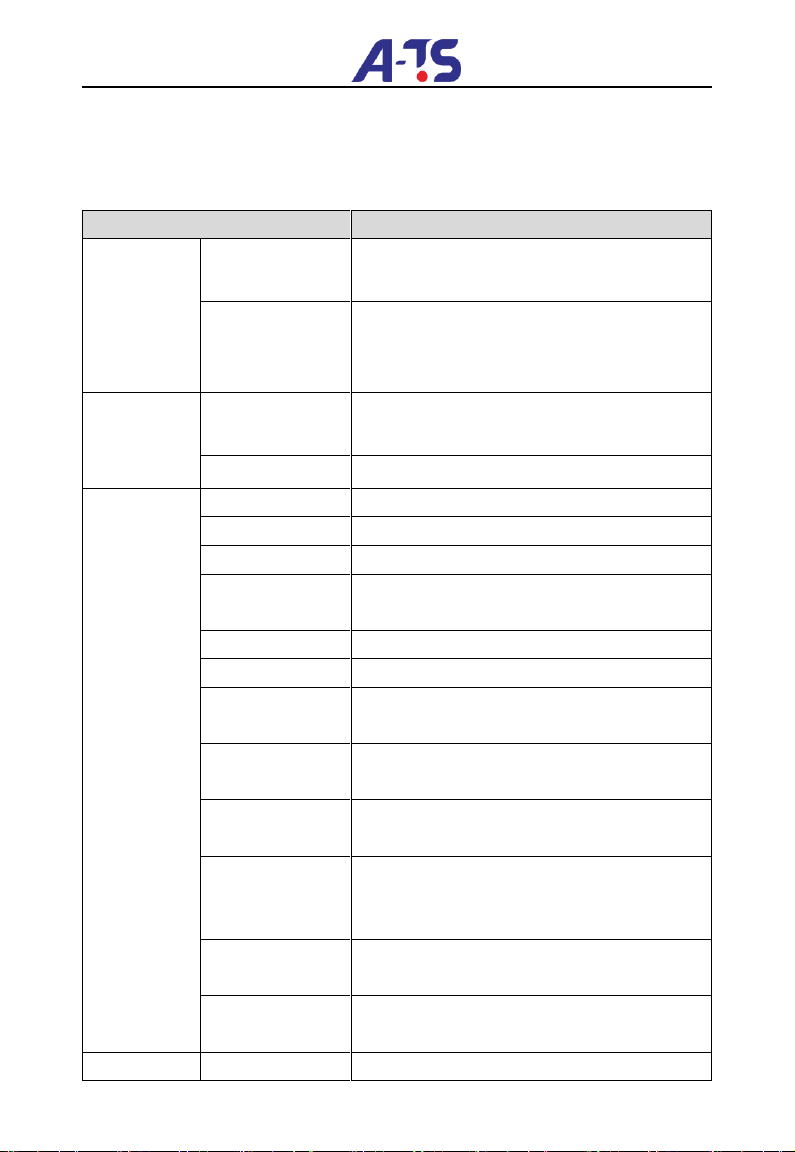

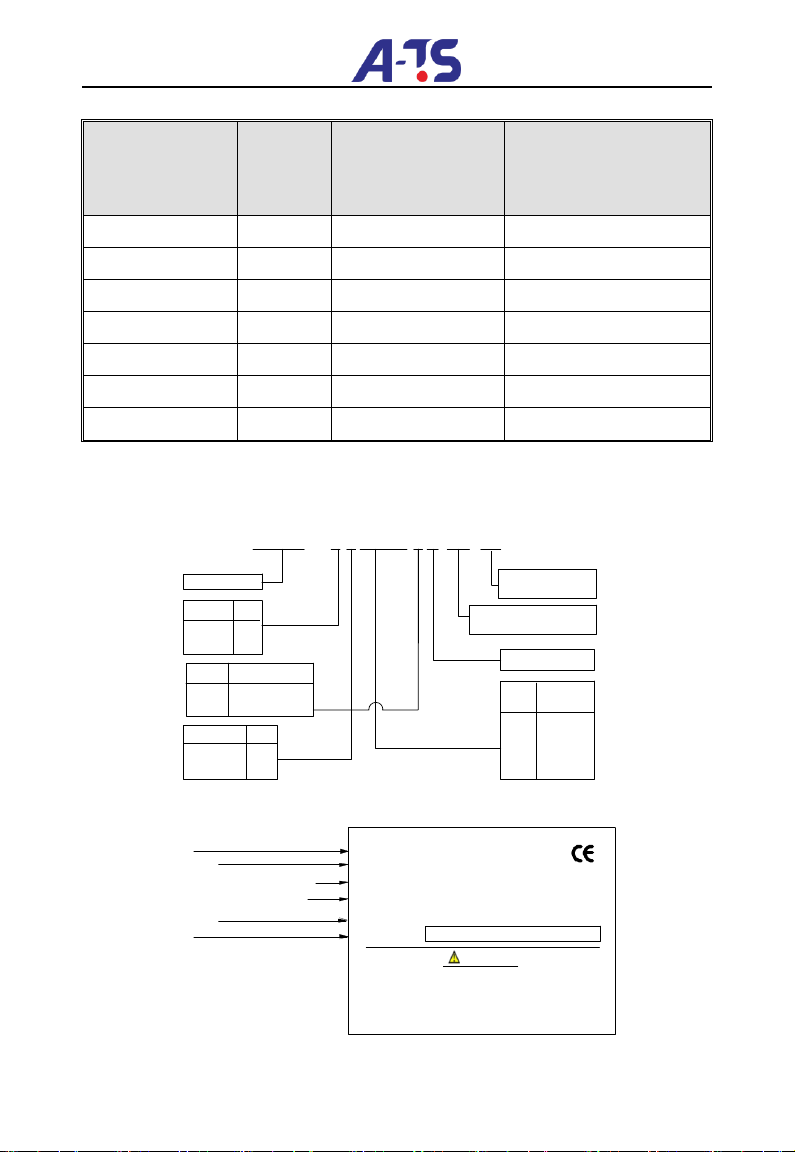

4.2.1 DT100 Models

A-TS 18

https://a-ts.cn/en/

Table 4-2 DT100 general purpose series

Model

Rated

capacity

( KVA )

Rated output

current ( A )

Applicable motor

power ( KW )

DT100-2S0004G

1.0

2.5

0.4

DT100-2S0007G

1.5

4.0

0.75

DT100-2S0015G

3.0

7.5

1.5

DT100-2S0022G

4.0

10.0

2.2

DT100-4T0007G

1.5

2.3

0.75

DT100-4T0015G

3.0

3.7

1.5

DT100-4T0022G

4.0

5.0

2.2

4.2.2 Ordering information of DT100 series

Please refer to Figure 4-1a and Figure 4-1b.

Series

Power

(KW)

Code

0004

0015

0022

0.4

1.5

2.2

-4 T 0 0 2 2 G B

DT100

Input Code

Three Phase T

Single Phase

Voltage Code

220V 2

380V 4

Code Type

Constant

torque

G

-XX-XX

Special machine code:

GM Series changed to default

Design version:0~99

0007 0.75

S

Built - in brake unit

Figure 4-1a DT100 Model Designation

DT100-4T0022G

2.2KW

3PH AC 380-440V 5.8A 50/60HZ

3PH AC 0-440V 5.0A 0~650HZ

MODEL :

POWER :

INPUT

:

OUTPUT:

S/N:

Model

Motor power

Rated input voltage, current and frequency

、

、

Design version

WARNING

* Risk of electric shock

*

*

VS 0000 0219 0000 0000

Barcode

:

Output voltage range rated current and

frequency range

Wait 10mins after power down before removing

the cover

Follow all the instructions in the manual before use

Figure 4-1b DT100 series nameplate

A-TS 19

https://a-ts.cn/en/

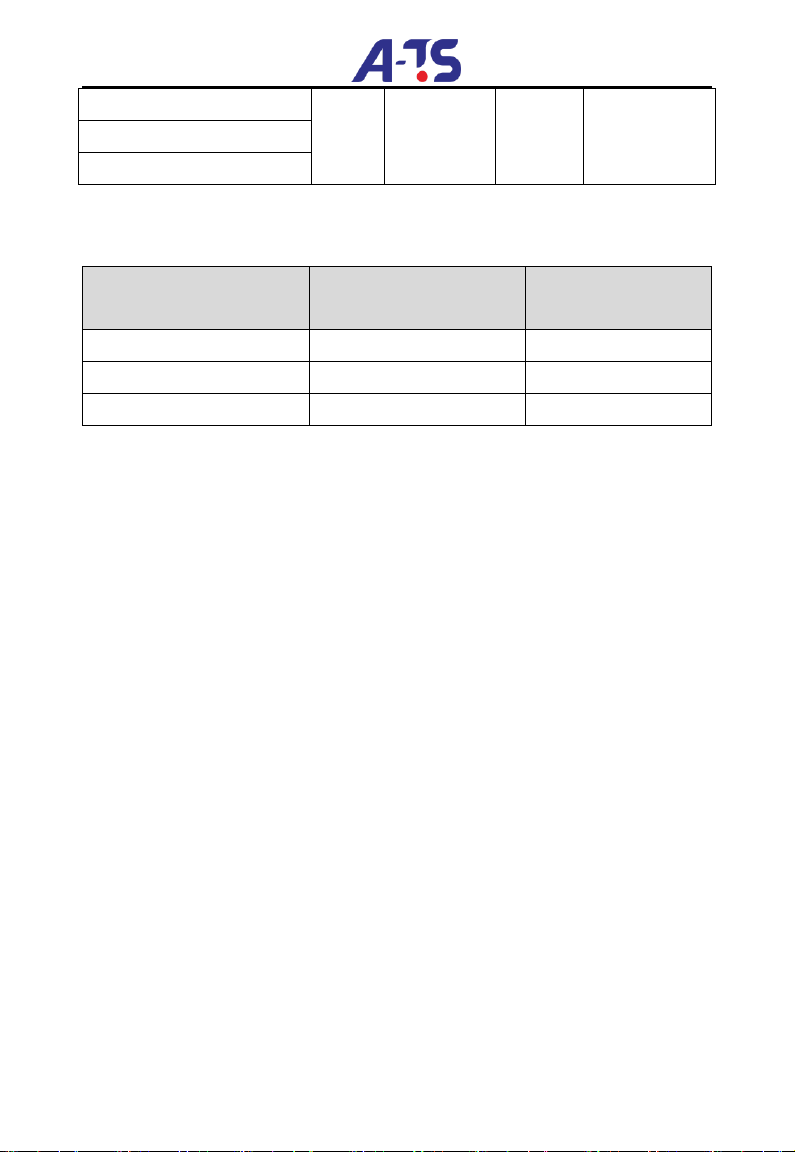

4.2.3 Demision

Please refer to Figure 4-2

Figure 4-2 DT100 series inverter size

Note: Net weight, 1.04KG

Gross weight ( including user manual after package ) , 1.22KG.

4.2.4 LED Keypad Display Unit Size

Through it, operation and configuration of the inverter can be done.

Please refer to its size and configuration in Figure 4-3.

Figure 4-3 Keypad display unit

Model No.

L

( mm )

W ( mm )

H

( mm )

Weight

( Kg )

DT100-2S0004G

146

92

123.52

1.22

DT100-2S0007G

DT100-2S0015G

DT100-2S0022G

A-TS 20

https://a-ts.cn/en/

DT100-4T0007G

DT100-4T0015G

DT100-4T0022G

4.2.5 Optional Parts

Table 4-3 Braking resistor suggested

Model

Suggested value of

resistance

Suggested power

DT100-4T0007G

250-350Ω

100W

DT100-4T0015G

200-300Ω

200W

DT100-4T0022G

100-250Ω

250W

DT100 series inverter ( 3phase product ) is equipped with braking unit.

If there is a need for energy-consuming braking, please select a braking

resistor in Table 4-3.

The Table 4-3 above is a guide reference only. Users can choose

different braking resistance and power according to each application.

However, please remember that the braking resistance shouldn’t be

lower than the above suggested value, but the power is allowed to be

higher than the recommend numbers. Users need to select the right

braking resistors according to each application case,there are quite a few

aspects which will determine your choice of the resistors, such as the

power of the motor, system inertia,deceleration time, the energy of the

load etc. The greater the system inertia is, the shorter the required

deceleration time is required,then the braking frequency will be increased,

which means you need to choose a bigger power braking resistor with a

lower braking resistance.

Note: the 220V single phase inverter is not with buit-in brake unit.

This manual suits for next models

7

Table of contents